PRODUCT OFFERING FOR RIGID POLYURETHANE FOAMS

Cardolite polyols based on Cashew Nutshell Liquid (CNSL) technology are functionalized to provide specific handling and performance properties. A wide range of viscosities, hydroxyl values, molecular weights, and functionalities can be achieved with CNSL technology to meet different application requirements in rigid foams. The intrinsic benefits inherited from CNSL technology translate into polyols with fast reactivity, good compression strength and fire resistance, hydrophobicity, and good compatibility with various blowing agents.

NX-9020 – NEW RENEWABLE POLYOL FOR RIGID FOAMS

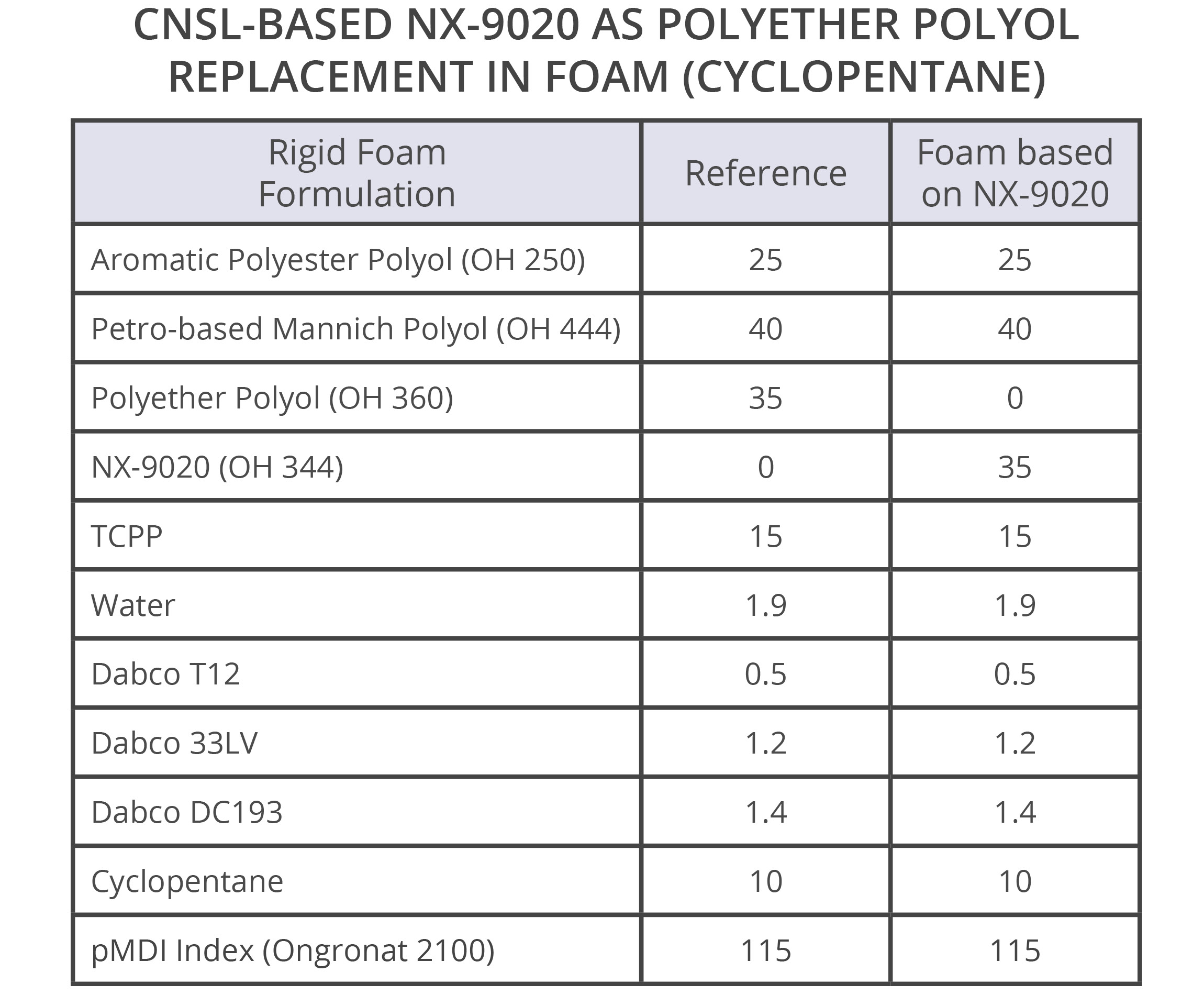

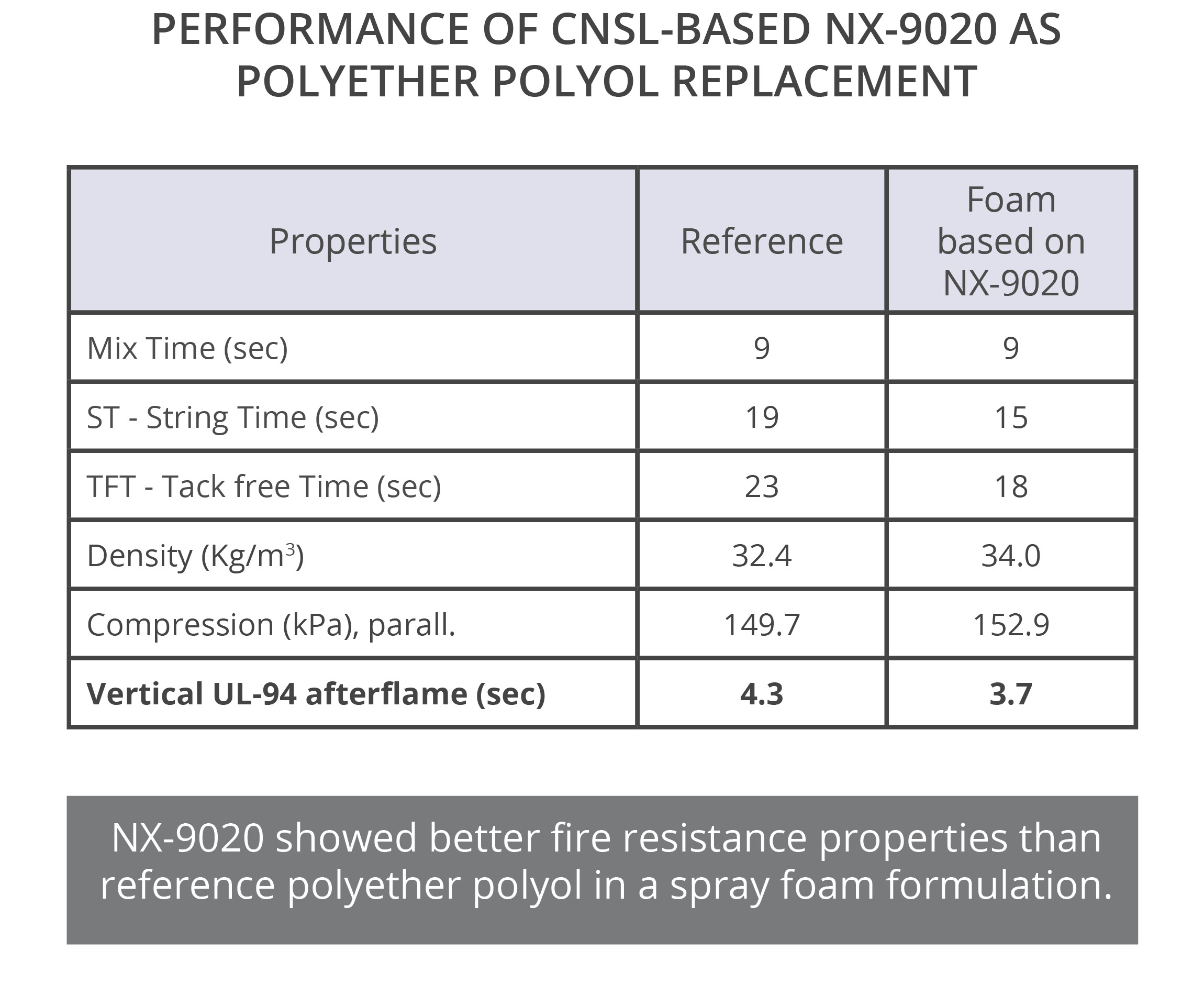

Cardolite NX-9020 CNSL-based polyether polyol is an excellent replacement for standard glycerin/sorbitol/sucrose initiated polyether polyols commonly used in rigid foams. This very high bio-content polyol provides aromaticity for better fire protection, and water and moisture resistance that result in better dimensional stability. Foams based on NX-9020 tend to show faster reactivity than traditional petroleum-based polyether polyols, which allows for catalyst reduction. Moreover, NX-9020 shows good reactivity stability with HFO blowing agents. This polyol is suitable for use in spray foams, insulation panels and boardstocks, pour-in-place and injection foams.

CNSL POLYOLS AS ADDITIVES IN PU FOAMS

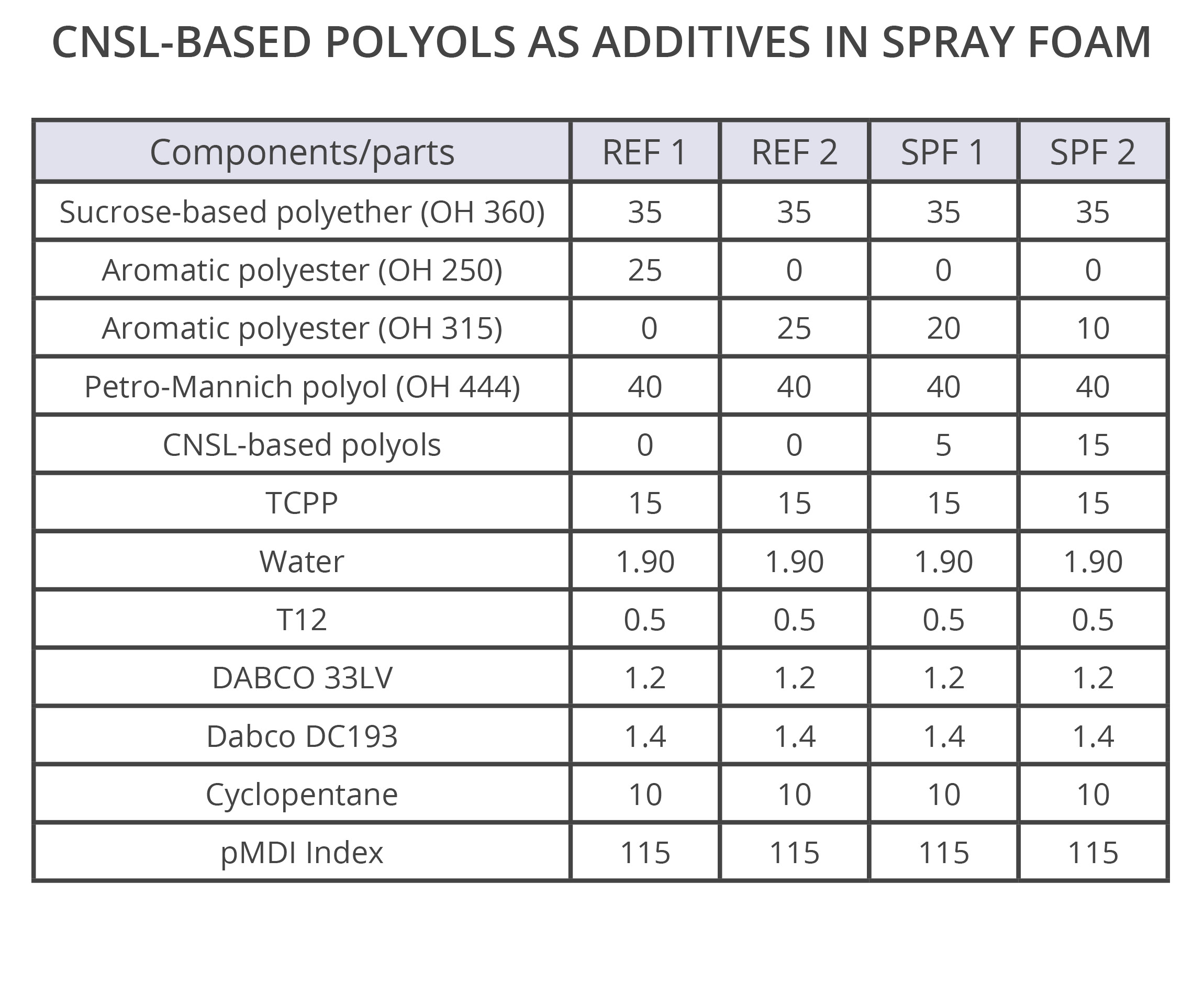

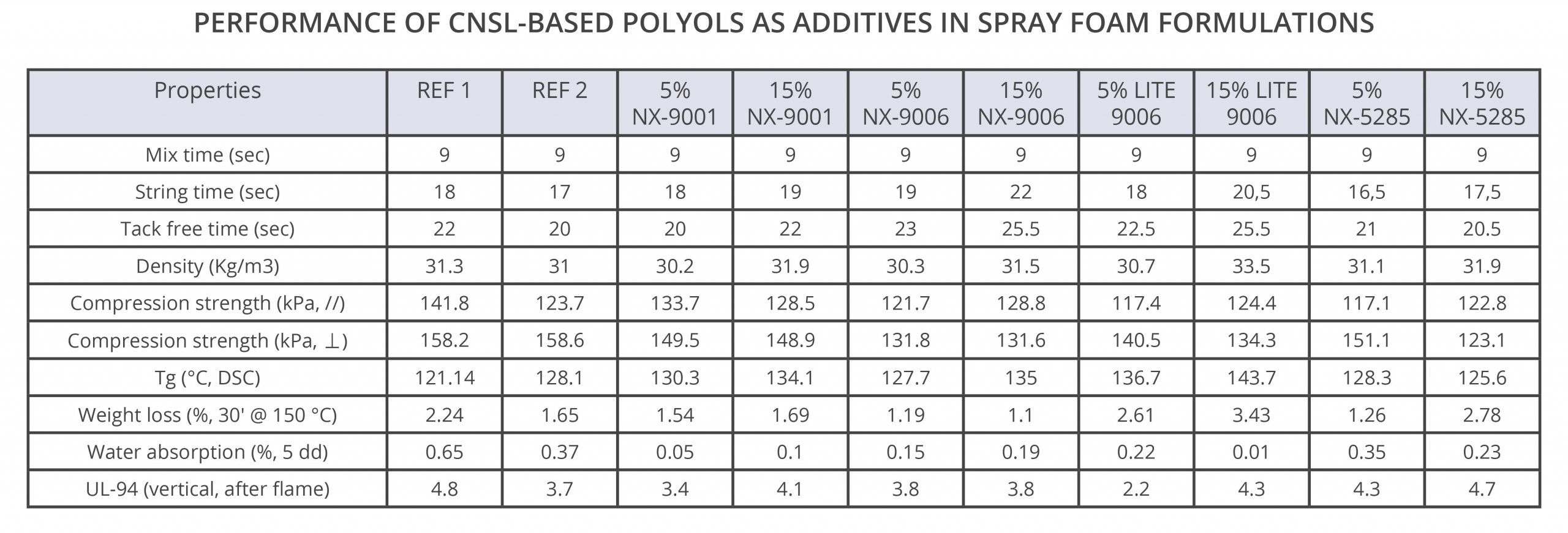

Cardolite CNSL-based Novolac and aromatic polyols are suitable for use as the main polyol resin or as modifiers at lower use levels (5 to 15%) in polyurethane rigid and flexible foams. The addition of these polyols can help increase bio-content and reduce costs as well as improve targeted performance attributes. For instance, the spray foam study shown on this page, indicates that CNSL polyols can be partial replacements for aromatic polyester polyols without the need to reformulate the polyurethane foam.

In general, these polyols are good tools to lower water absorption of the final foam while maintaining good reactivity, fire resistance, compression strength and thermal stability. Our evaluations demonstrated that at 5%, NX-9001 and LITE 9006 also provided an improvement in UL 94 performance. In addition, NX-9001 showed excellent compression strength and similar reactivity to standard aromatic polyol. Foams modified by NX-9006 delivered the best thermal stability as observed by the very low weight loss after exposure to 150°C for 30 min. NX-5285 is another good option for more economical formulations that can accept a darker color.

EXCELLENT COMPATIBILITY

CNSL-based polyols, even if characterized by a high hydrocarbon content, contain enough polar groups (e.g. amino, hydroxyl, esters) to guarantee excellent compatibility with polyether polyols and petro-based Mannichs. As seen with other natural oil polyols, CNSL polyols show limited miscibility with polyester polyols (both aliphatic and aromatic). However, this limitation can be easily overcome by properly tuning the composition of the B-part of the polyurethane formula. As an example, a polyether polyol may be used as a co-polyol, balancing the CNSL-polyol/polyester polyol ratio. Other options include the use of non-ionic surfactants, emulsifiers or blowing agents with a solvent effect (e.g. methyl formate).

Moreover, cardanol-based polyols demonstrated excellent miscibility with methyl-formate, n-pentane and HFO, better than petro-based Mannich and polyester polyols, while the compatibility with HFC is comparable to commercial references. Polyols must exhibit good compatibility with the blowing agent of choice to ensure adequate final foam properties and B-part stability.

POLYOLS COMPATIBILITY WITH BLOWING AGENTS*

| Polyol Type | Polyol/ methyl-formate | Polyol/ HFC | Polyol/ n-pentane | Polyol/ HFO (Solstice LBA) |

|---|---|---|---|---|

| NX-9101 | ≥ 40 | ~10 | ≥ 40 | ≥ 40 |

| NX-9102 | ≥ 40 | ~12 | ≥ 40 | ≥ 40 |

| NX-9104 | ≥ 40 | ~10 | ≥ 40 | ≥ 40 |

| Petro-Mannich polyol (OH 425) | ≥ 40 | ~25 | ~4 | ≥ 40 |

| Petro-Mannich polyol (OH 450) | ≥ 40 | ~26 | ~2 | ≥ 40 |

| NX-9006 | ≥ 40 | ~6 | ≥ 40 | ≥ 40 |

| NX-9001 | ≥ 40 | ~6 | ≥ 40 | ≥ 40 |

| NX-9020 | ≥ 40 | N/A | ≥ 40 | ≥ 40 |

| Aromatic-PA polyester polyol (OH 240) | ≥ 40 | ~6 | ~2 | ~9 |

| Aromatic-PET polyester polyol (OH 240) | ≥ 40 | ~12 | ~2 | ~25 |

| Aliphatic polyester polyol (OH 350) | ≥ 40 | ~14 | ~1 | ~23 |

| Polyether polyol (OH 360) | ≥ 40 | ≥ 40 | ≥ 40 | ≥ 40 |

*Max wt. for single phase solution (%) after 24 hrs (60/40 w/w)

≥ 40 indicates full miscibility

CNSL POLYOLS COMPATIBILITY WITH OTHER POLYOLS

| Petro-based Polyols | NX-9101 | NX-9102 | NX-9104 | NX-9001 | NX-9006 | NX-9020 |

|---|---|---|---|---|---|---|

| Mannich (OH 425) | Excellent | Excellent | Excellent | Excellent | Excellent | Excellent |

| Aromatic Polyester (OH 240) | Separation | Separation | Separation | Separation | Clear at 50/50 | Separation |

| Aliphatic Polyester (OH 350) | Separation | Separation | Separation | Separation | Clear at 50/50 | Separation |

| Propoxylated sorbitol polyether (OH 300) | Excellent | Excellent | Excellent | Excellent | Excellent | Excellent |

| Alkoxylated sucrose based polyether (OH 360) | Excellent | Excellent | Clear at 50/50 | Excellent | Excellent | Excellent |

| Alkoxylated sucrose/DEG based polyether (OH 440) | Excellent | Excellent | Excellent | Clear at 50/50 | Excellent | Excellent |

| Ethoxylated/propoxylated glycerine based polyether (OH 33) | Excellent | Excellent | Clear at 50/50 | Excellent | Excellent | Excellent |

| PPG 1000 (OH 114) | Excellent | Excellent | Excellent | Excellent | Excellent | Excellent |

| Propoxylated glycerine polyether polyol (OH 156) | Excellent | Excellent | Excellent | Excellent | Excellent | Excellent |

| Propylene oxide/ethylene oxide based polyether polyol (OH 48) | Excellent | Excellent | Excellent | Excellent | Excellent | Excellent |

REPLACEMENT FOR PETRO-BASED MANNICH POLYOLS

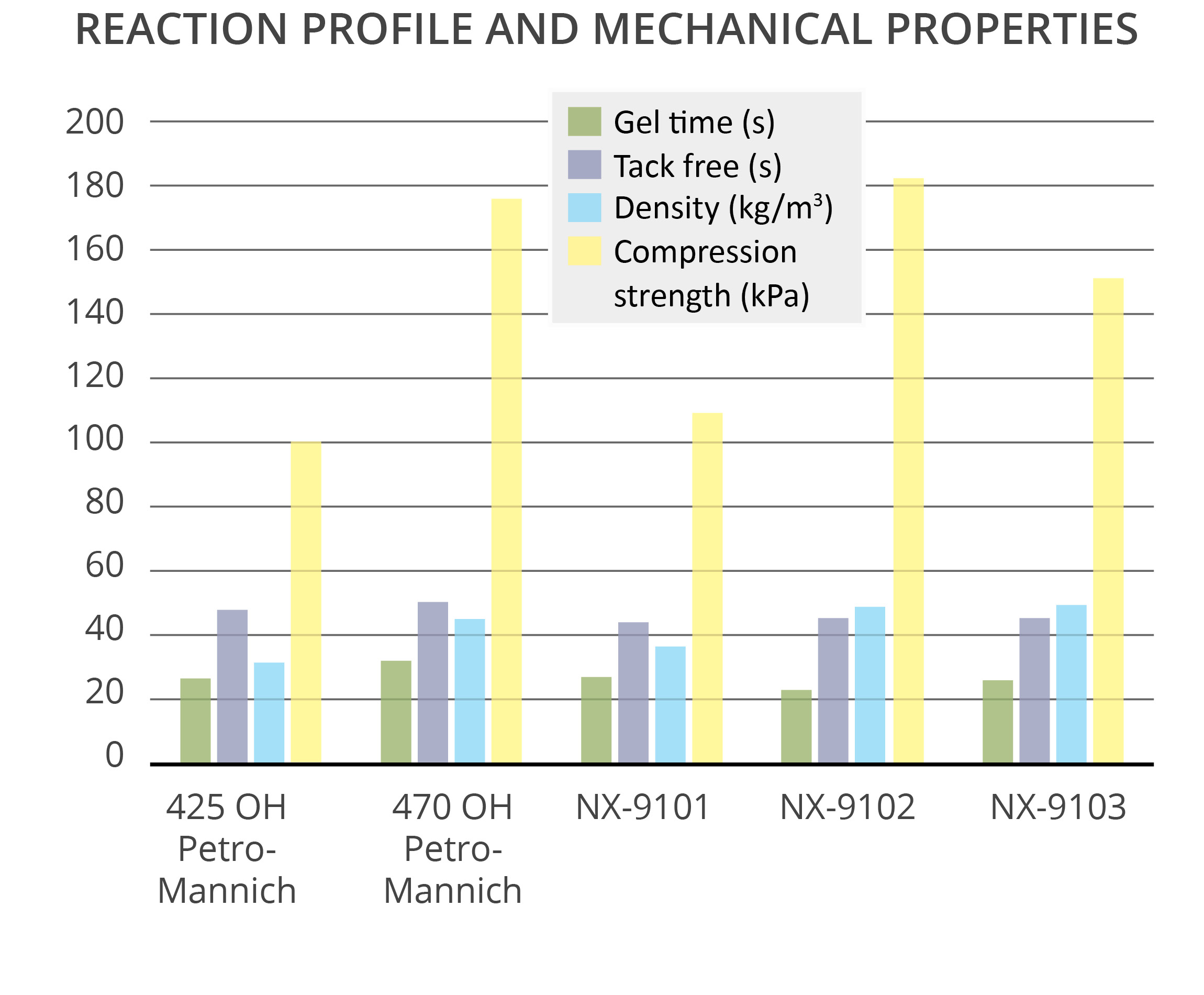

CNSL-based Mannich polyols are lower in viscosity and have a broader range of hydroxyl values than petro-based analogues, and offer excellent field processing, good dimensional stability, low friability, good flow, very uniform fine cell structure and high closed cell content. Moreover, the surfactant-like properties from CNSL derivatives and their inherent fast reactivity allows foam formulators to reduce the use of expensive additives such as blowing and gelling catalysts as well as surfactants.

Due to the nature of the hydroxyl groups within each derivative, CNSL-based Mannich polyols exhibit reaction profiles comparable or faster than standard commercial Mannich polyols, thus being suitable for the majority of rigid polyurethane systems, including PIR systems. Moreover, the combination of aromatic content and long alkenyl chain of CNSL Mannich polyols delivers comparable or superior compression strength at similar density levels.

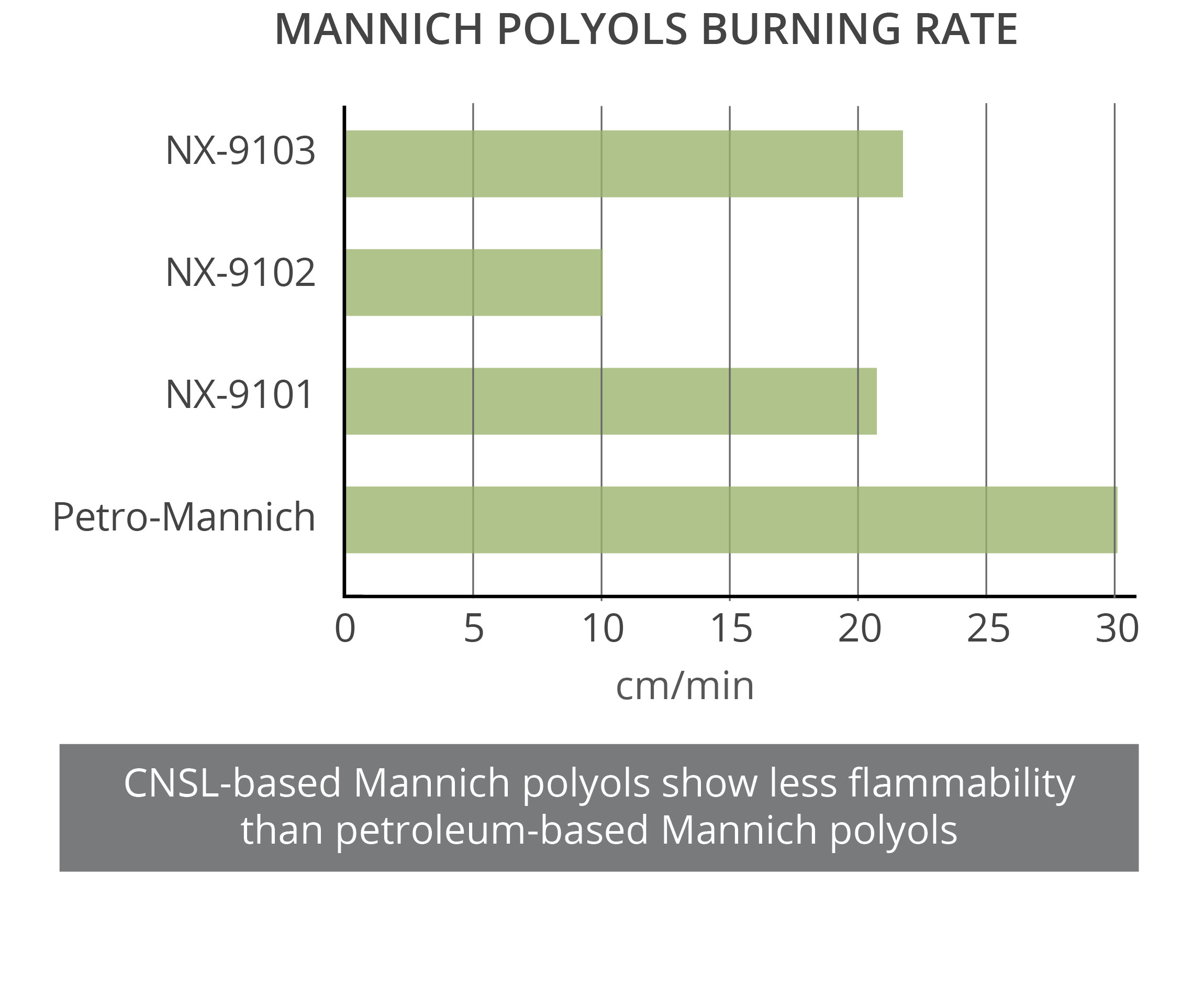

The high aromatic content of CNSL-based Mannich polyols and overall composition results in excellent fire resistance properties that can be seen by lower burning rates and less flammability than petro-based counterparts.

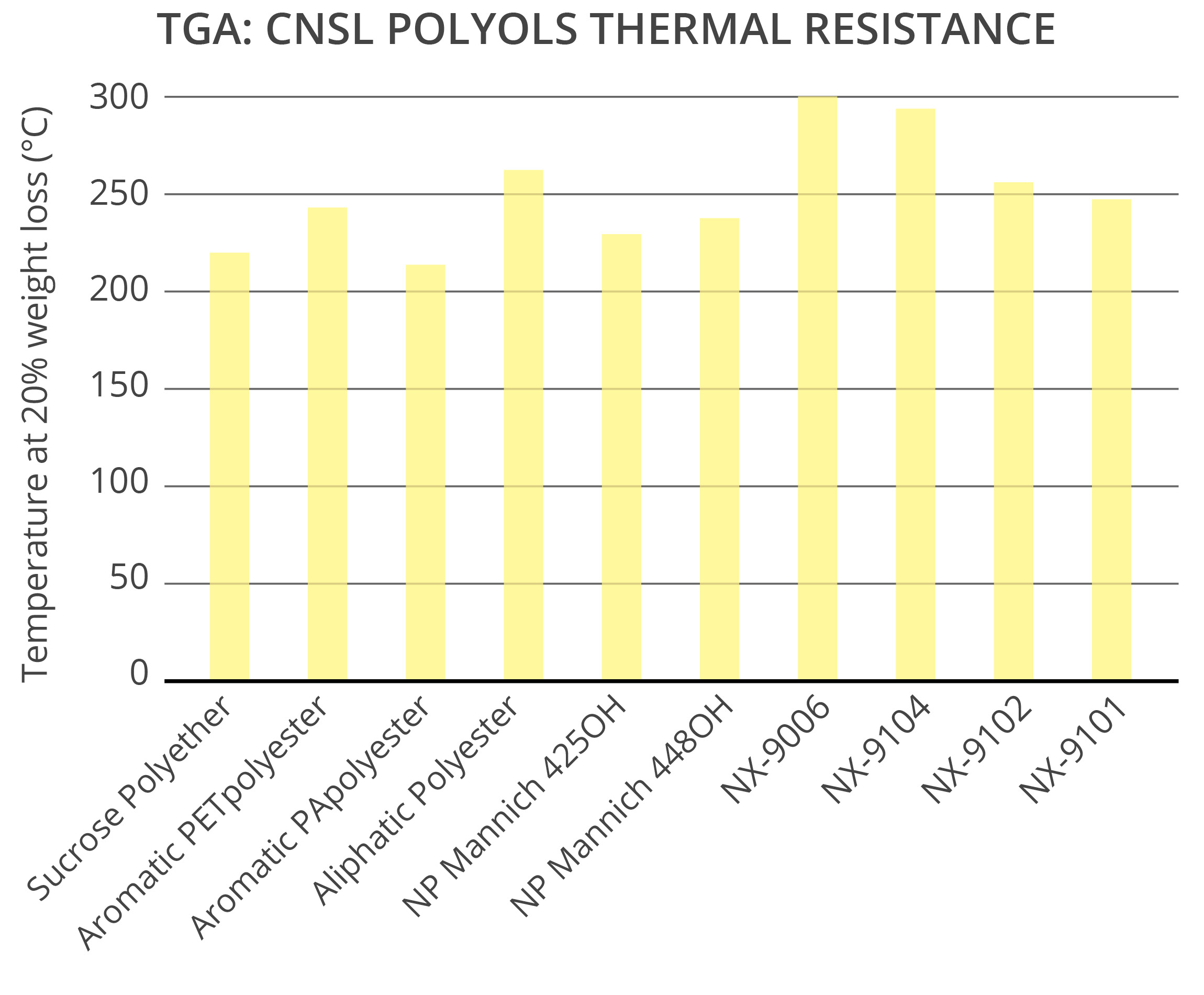

IMPROVED THERMAL RESISTANCE

CNSL-based polyols are expected to provide good thermal resistance due to the aromatic ring in their backbone. Thermal gravimetric results shown in the TGA graph on the left confirm that in average, CNSL-based polyols can withstand higher temperatures than typical polyether polyols and petro-based Mannich polyols. CNSL-based polyols also performed similarly or better than aliphatic and aromatic polyesters. Results were reported based on the temperature required for a 20% polyol weight loss.

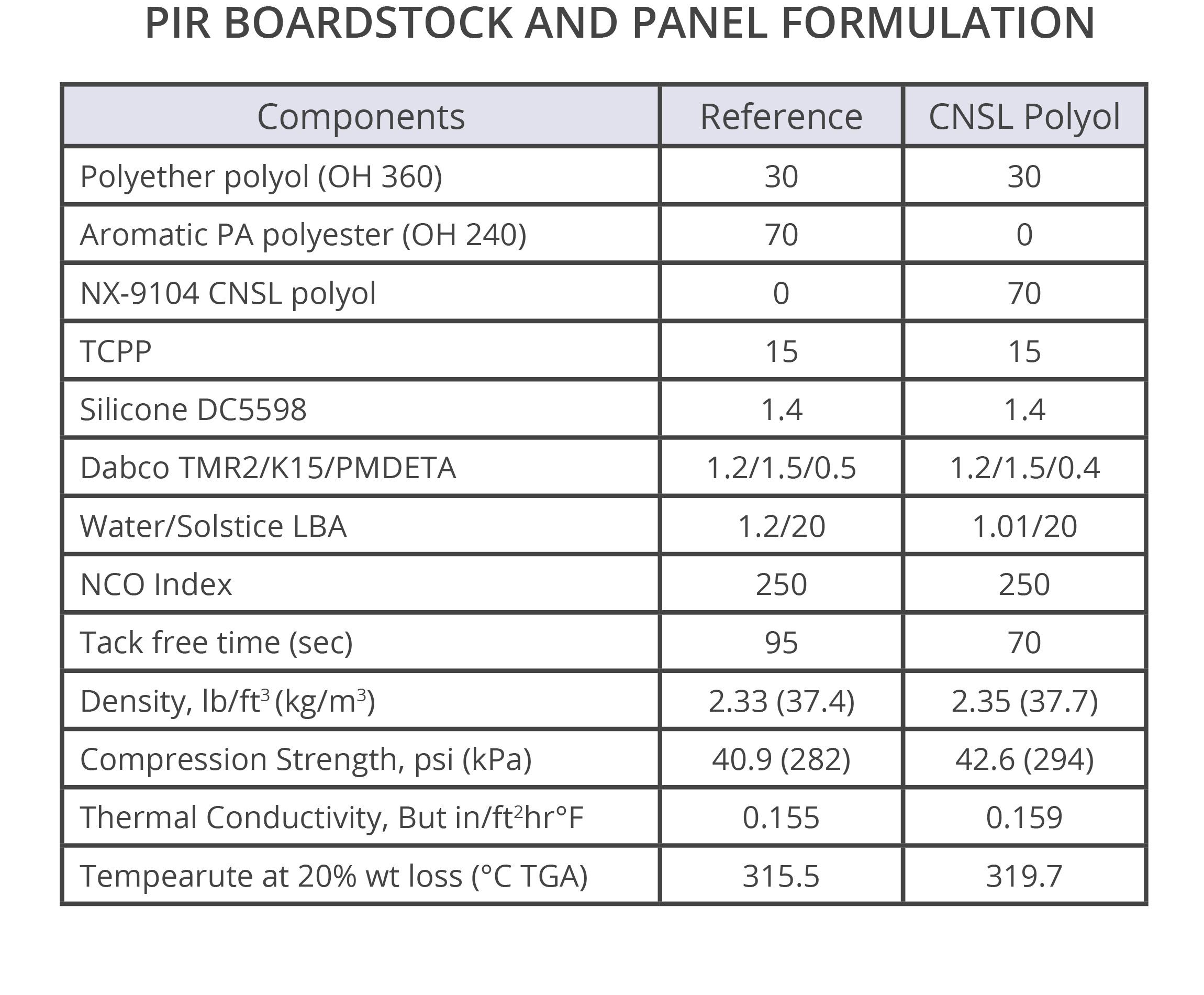

Furthermore, the full replacement of an aromatic polyester with NX-9104 in the PIR formulation on the left, results in a faster cure profile even with the use of less amine catalyst, similar density and slightly higher compression strength. The aromatic polyester offered higher LOI, but NX-9104 gave similar thermal conductivity and slightly better TGA results.