IMPROVING PERFORMANCE WITH RENEWABLE TECHNOLOGY

Cardolite offers a variety of cardanol grades and cardanol derivatives that can be used as monomer or polymer building blocks in specialty chemicals. Cardanol is the main component distilled from Cashew Nutshell Liquid (CNSL), an annually renewable and non-food chain phenolic resin extracted from the honeycomb of the cashew nut.

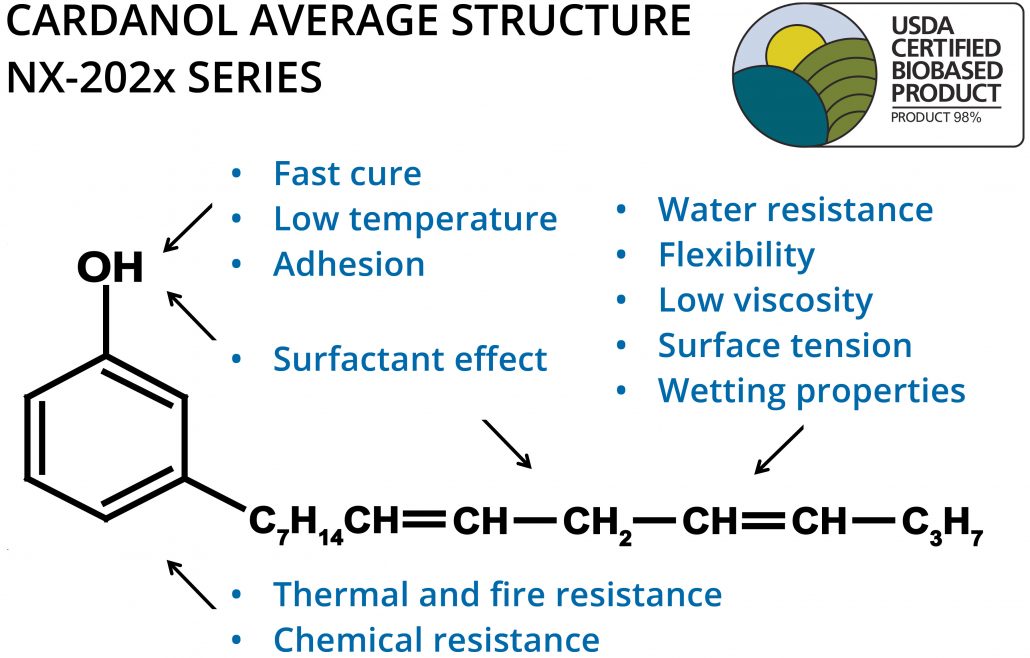

This material is a versatile molecule that can be functionalized in many different ways. Reactive sites include the phenolic OH, aromatic ring and double bonds of the long aliphatic side chain. Epoxy and polyol resins, ethoxylate surfactants, amines as curing agents, benzoxazines, and phenolic and polyester resins are just some examples of resins made from cardanol. For years, cardanol and its derivatives have been successfully used in the coatings, adhesives, composites, foam and friction industries due to their unique properties. Moreover, cardanol is a safer, non-toxic replacement for nonyl phenol and similar petro-based phenols.

Given the performance and health, environmental and safety benefits of cardanol, this material has also been used as modifier in many applications. For instance, cardanol can be a diluent, flexibilizer and accelerator for epoxy systems, an isocyanate blocking agent in polyurethanes, a plasticizer in plastics and PVC, and a dust suppressor in mixing processes.

BUILDING BLOCKS WITH A WIDE RANGE OF PROPERTIES AND PERFORMANCE

CNSL can be processed to yield different cardanol grades with a wide range of color, odor, and purity among other parameters. Recently, Cardolite developed a proprietary process technology that enables very high purity cardanol grades with ultra light color (Gardner of 1 or less) and good stability over shelf life. This leap forward in CNSL processing technology is expanding the use of cardanol as an intermediate and as a modifier. Cardanol is a suitable replacement for potentially toxic phenol diluents such as nonyl-phenol as it provides lower viscosity, better flexibility, and similar acceleration effects to epoxy-amine reactions. Please click on the link to learn more about the Ultra LITE technology.

Cardanol is also available in its partially and fully hydrogenated forms called NC-510(HP) and NC-510FH, respectively. NC-510 is a waxy solid that has been used as an intermediate in color films and can be a versatile building block for other chemistries.

CARDANOL GRADES AND PROPERTIES

| Product | Color Gardner | Viscosity (cPs) | Typical Purity (%) | Description | Documents |

|---|---|---|---|---|---|

| NX-2021 | ≤ 18 | 45 - 75 | 87 - 90 | Standard cardanol grade | TDS MSDS (USA) MSDS (EU) |

| NX-2022 | 5 - 8 | 40 - 60 | ≥ 95 | High purity cardanol | TDS MSDS (USA) MSDS (EU) |

| Ultra LITE 2023 | 1 | 40 - 100 | ≥ 96 | Ultra light, wet color stable cardanol | TDS MSDS (USA) MSDS (EU) |

| NX-2023 | ≤ 6 | 40 - 100 | ≥ 96 | Light, wet color stable cardanol | TDS MSDS (USA) MSDS (EU) |

| NX-2023D | ≤ 15 | 80 - 140 | 87 - 90 | Dark, wet color stable cardanol | TDS MSDS (USA) MSDS (EU) |

| NX-2024 | 4 - 9 | 45 - 60 | 87 - 90 | Low odor, standard purity cardanol | TDS MSDS (USA) MSDS (EU) |

| NX-2025 | ≤ 5 | ≤ 60 | ≥ 96 | Low odor, high purity cardanol | TDS MSDS (USA) MSDS (EU) |

| NX-2026 | ≤ 2 | ≤ 60 | ≥ 96 | Very light, wet color stable cardanol | TDS MSDS (USA) MSDS (EU) |

| NC-510 | solid | melting range 49-51°C | ≥ 90 | Partially hydrogenated cardanol | TDS MSDS (USA) MSDS (EU) |

| NC-510HP | solid | melting range 49-51°C | ≥ 96 | Higher purity NC-510 | TDS MSDS (USA) |