INDUSTRIAL AND TRANSPORTATION COATINGS

Cardolite offers a broad portfolio of products for industrial and transportation epoxy and polyurethane coatings. Formulators looking for solutions with excellent anti-corrosion properties, zero and low V.O.C., adhesion to various substrates, fast cure and long lasting protection can benefit from our offering.

OUTSTANDING PROTECTIVE & FUNCTIONAL PERFORMANCE

Very fast cure for sandable and wet-on-wet applications, excellent corrosion protection for thin coatings, adhesion to non-blasted substrates, good color and gloss retention, and universal and all-season solutions are some of the advantages provided by Cardolite products for industrial and transportation coatings.

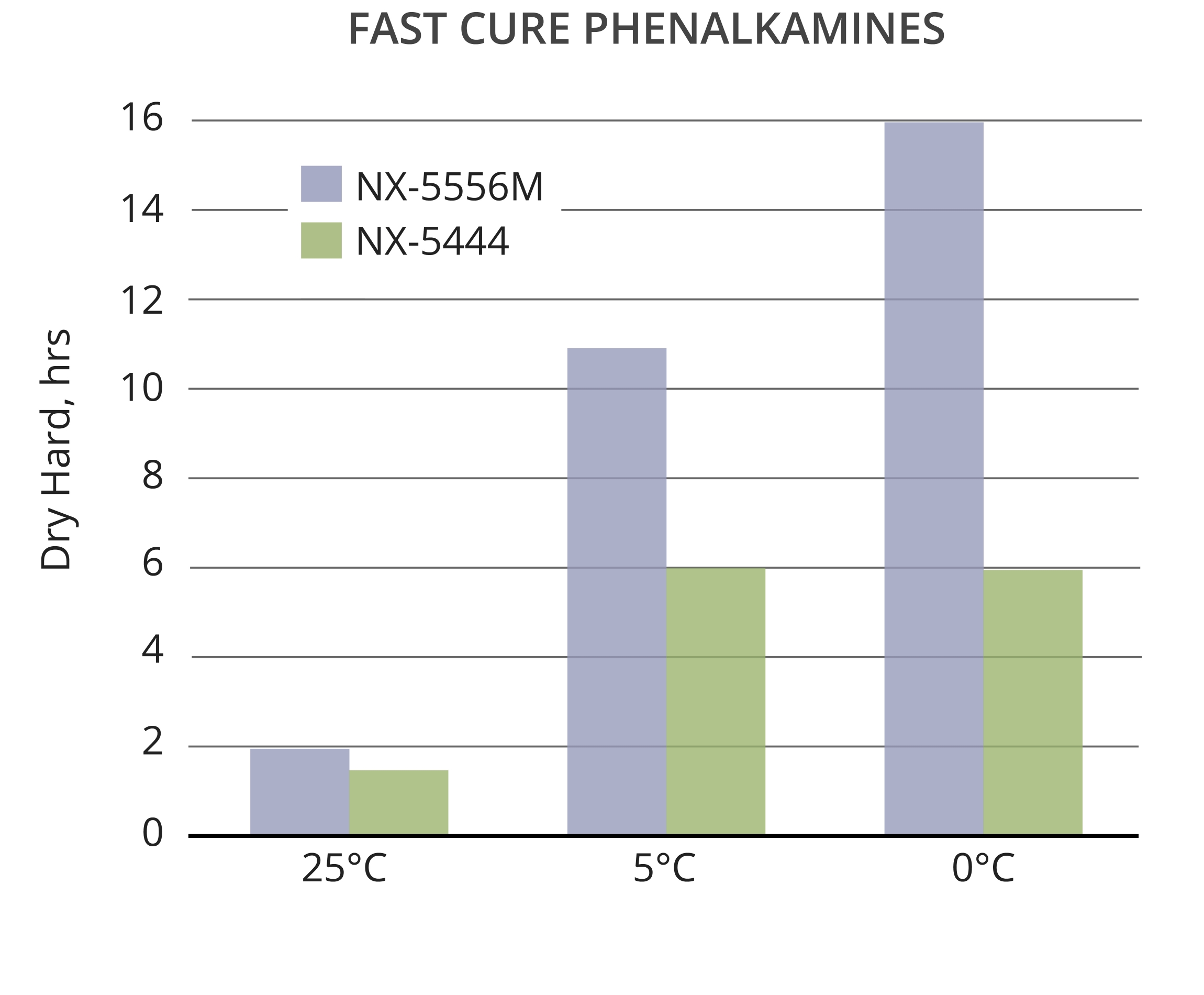

VERY FAST RECOATABILITY

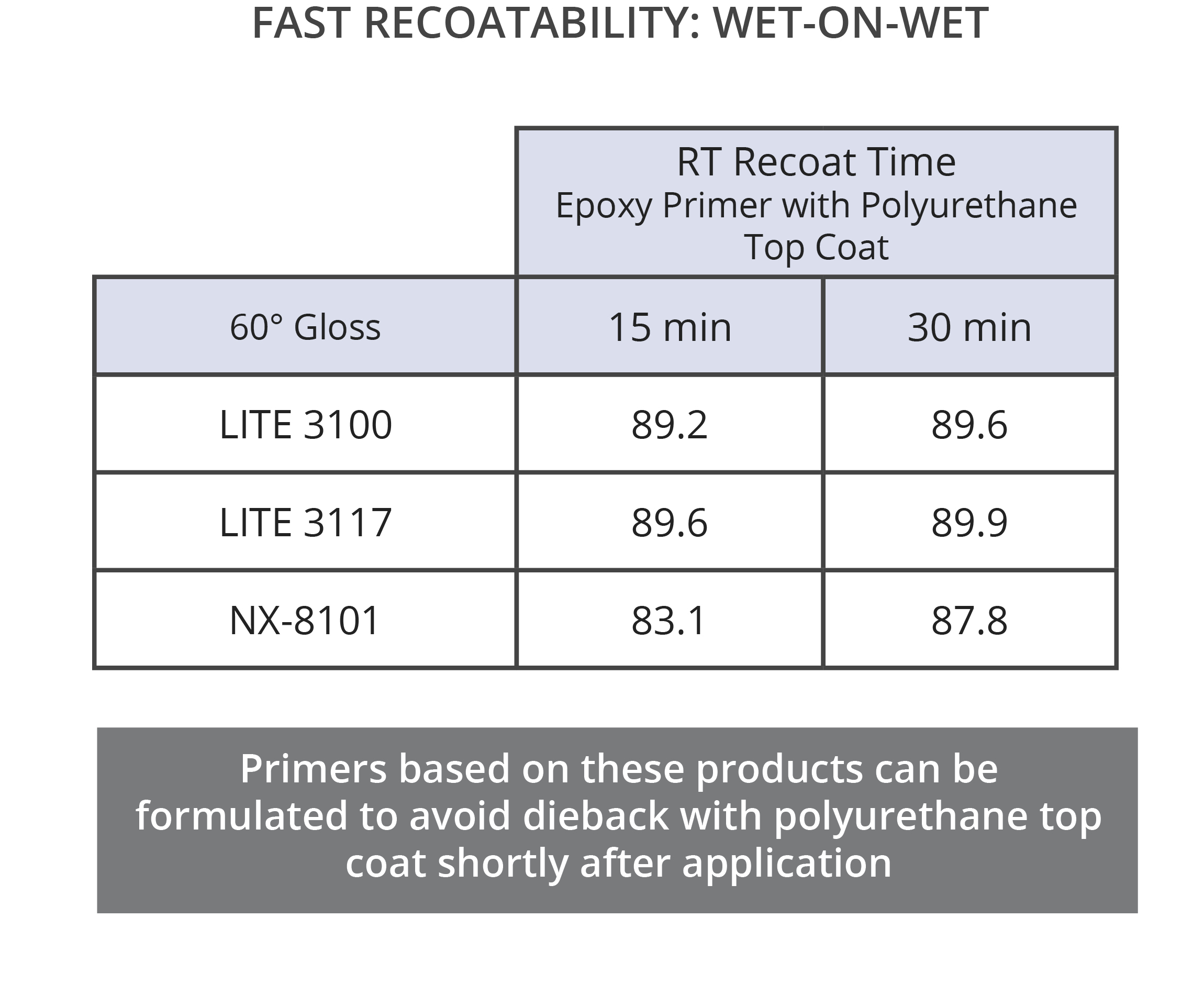

Cardolite offers epoxy curing agents for primers, midcoats, top coats, and direct-to-metal coatings for year round applications. With a broad selection of chemistries and properties, Cardolite offers phenalkamine and phenalkamide curing agents that provide very fast sandability and are also suitable for quick recoat in wet-on-wet applications resulting in fast productivity. Recoat times as quick as 15 min can be achieved with standard formulations without causing dieback with polyurethane top coat.

Moreover, the NX-8101 Series waterborne curing agents deliver fast cure in conditions as low as 10°C and 80% relative humidity and excellent wet-on-wet properties.

Our line of cardanol diluents act as an accelerator to epoxy-amine reactions in addition to increasing hydrophobicity of the system and can be used as a replacement for nonyl phenol.

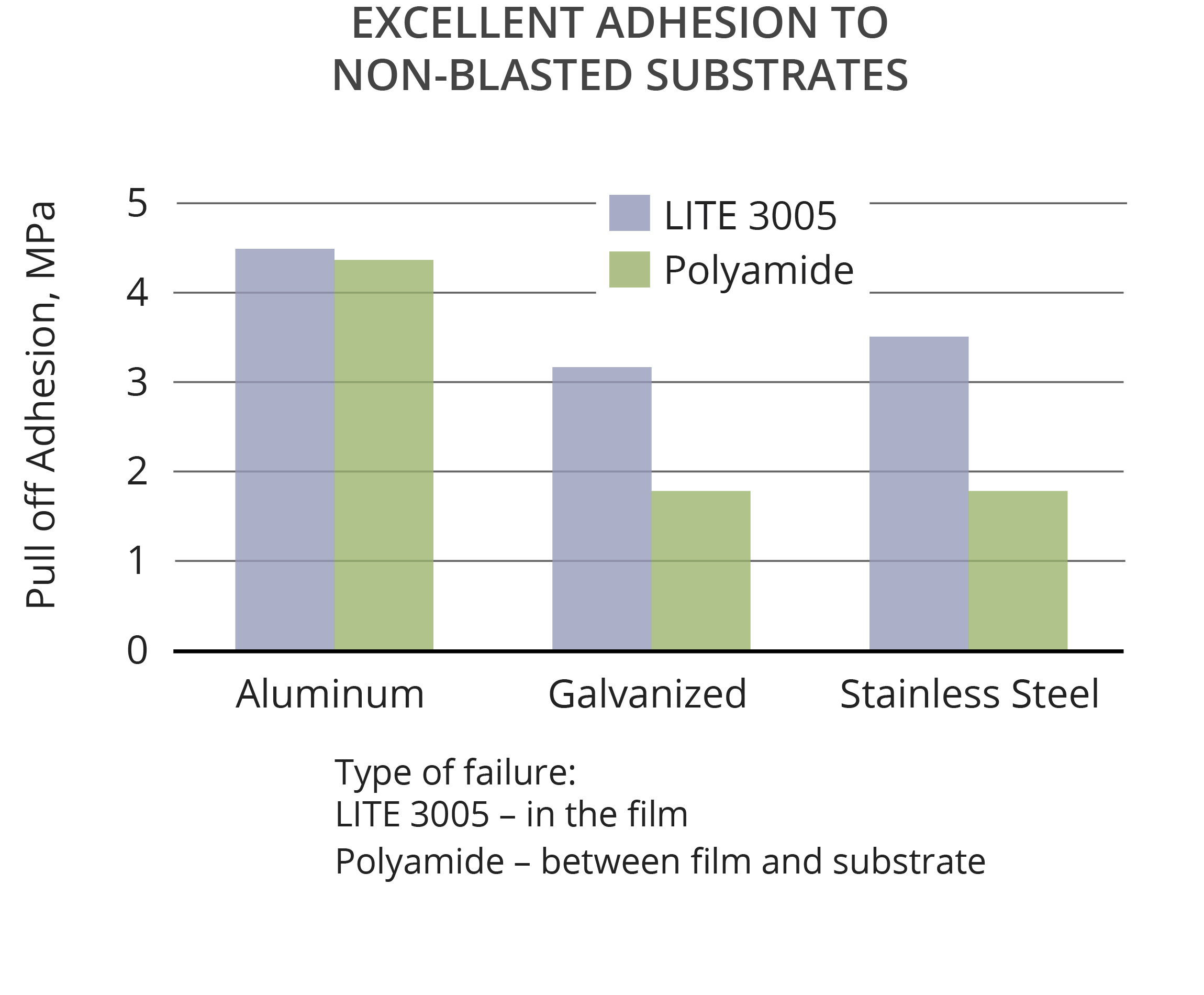

ADHESION TO NON-BLASTED SURFACES

Many industrial applications use non-blasted substrates such as aluminum and galvanized steel. Cardolite curing agents and diluents provide excellent adhesion to smoother surfaces that are typically challenging to protect. Excellent wetting properties, low viscosity and adhesion coupled with the hydrophobicity of cardanol based materials, results in long-lasting corrosion protection for superior durability.

This level of performance is true for field-applied, but also factory-applied applications encompassing application temperatures below zero degree celsius to > 40°C.

Cardolite diluents can be also considered as flexibilizers to improve impact resistance of applications that require the extra protection.

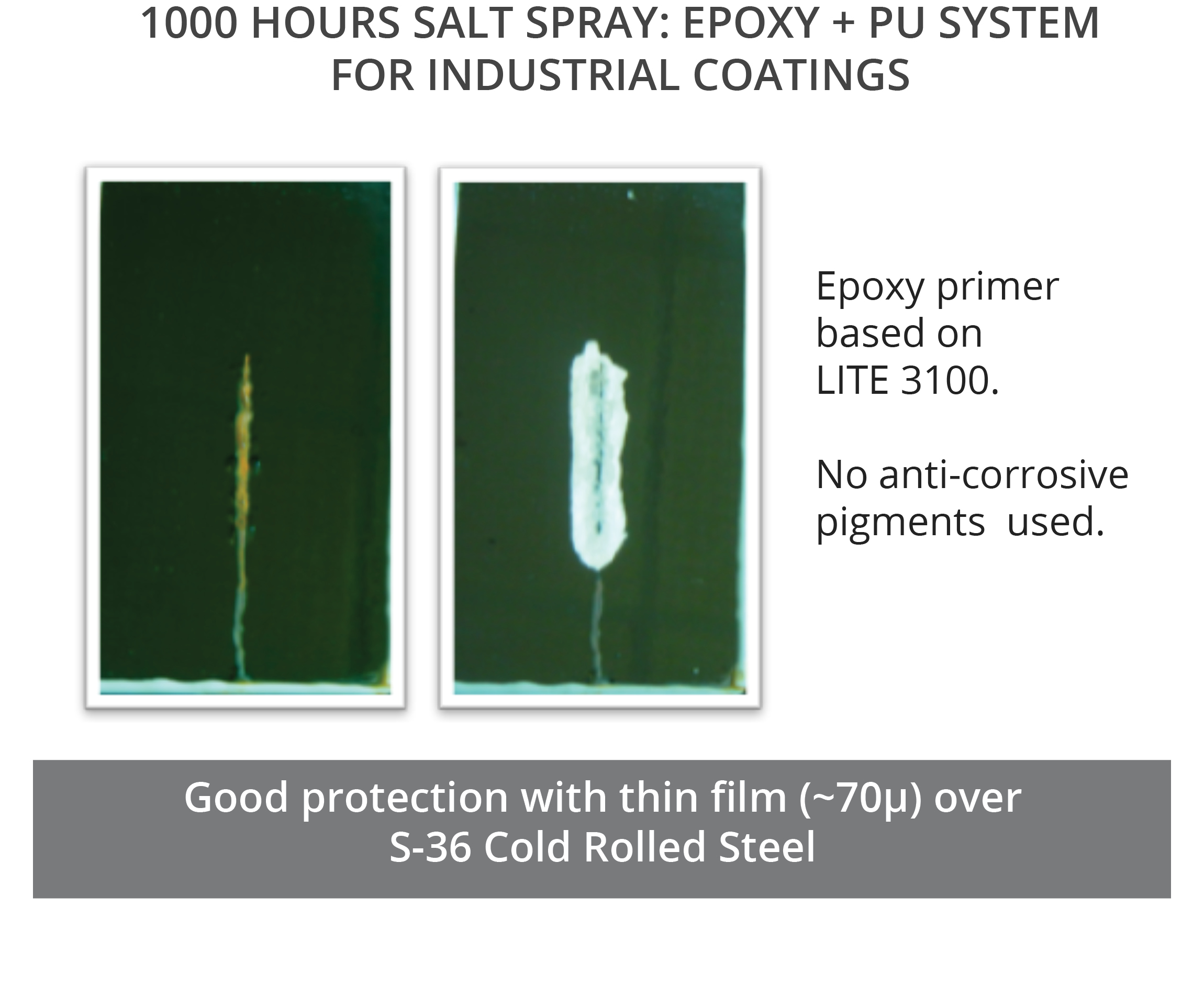

GOOD WEATHERABILITY WITHOUT COMPROMISING CORROSION PROTECTION

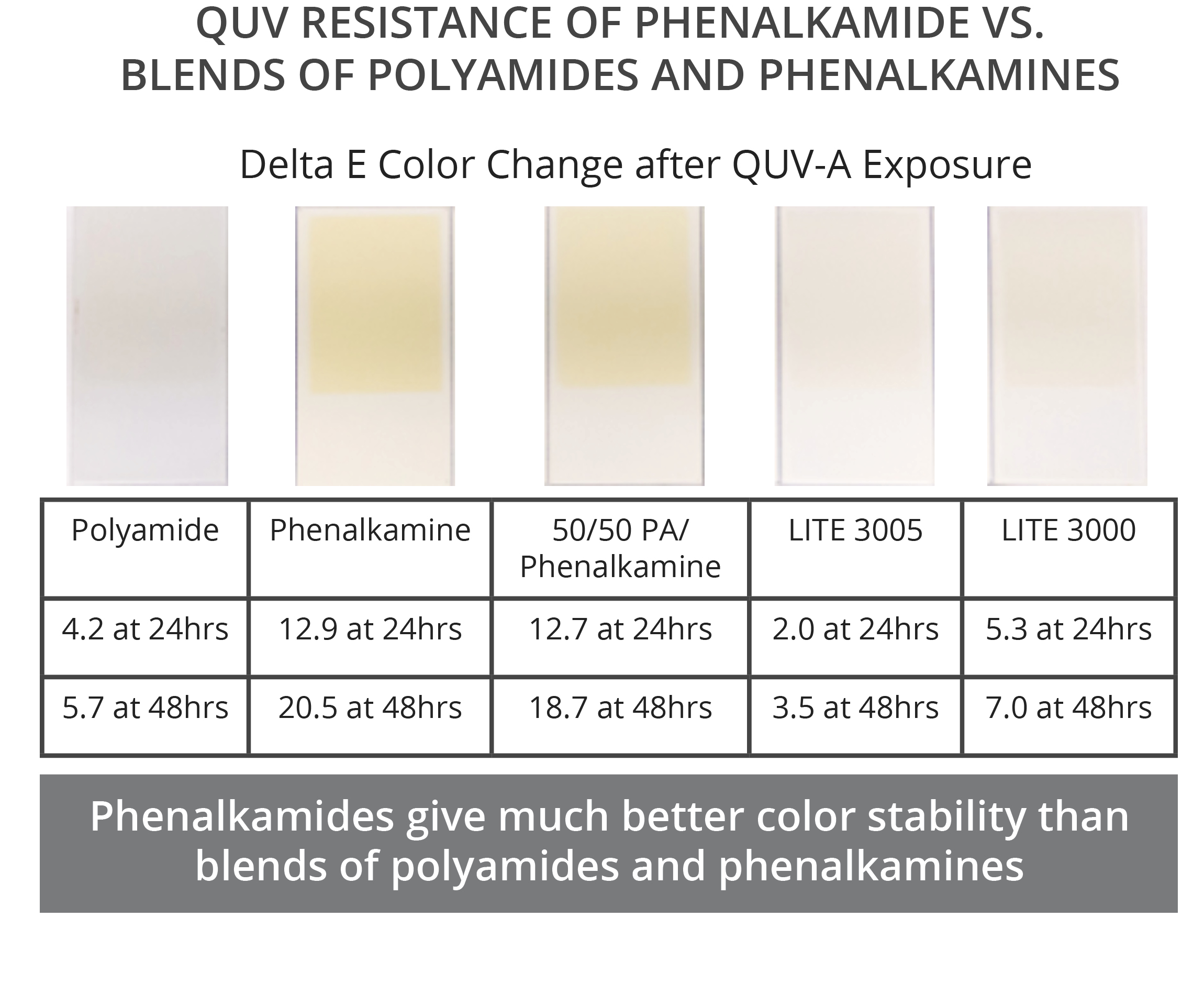

Cardolite’s phenalkamide product line, the LITE 3000 Series, was designed to provide good color and gloss retention while maintaining the excellent corrosion protection properties and fast cure speed of CNSL derived curing agents. The good UV resistance enables the use of phenalkamides in all layers, from primers to top coats as well as Direct-to-metal coatings.

Phenalkamides deliver much better yellowing resistance and gloss retention than blends of polyamides with phenalkamines due to its proprietary technology.

Cardolite’s innovative Ultra LITE diluents are also suitable for lighter epoxy coatings with good UV resistance.