Marine And Protective Coatings

OUR PRODUCT OFFERING

Cardolite offers a broad portfolio of products for marine & protective epoxy and polyurethane coatings. We provide solutions with excellent corrosion protection, ZERO and LOW V.O.C., easy handling and application, fast reactivity and long lasting protection. Please visit our epoxy curing agents, epoxy diluents and modifiers, and polyols and diols pages for more details on the grades offered for anticorrosion coatings.

OUTSTANDING PERFORMANCE IN EPOXY COATINGS

Our epoxy curing agents and diluents offering covers a wide range of performance properties. Our products are recommended for many marine and protective applications that also include oil and gas, mining, water and wastewater, tank lining, and other infrastructure markets. Formulators will find solutions with low VOC (high solids, solvent-free and waterborne), all-season curing, and for multi-layer use (zinc-rich, primer, midcoat, topcoat, direct-to-metal) in our coatings product lines.

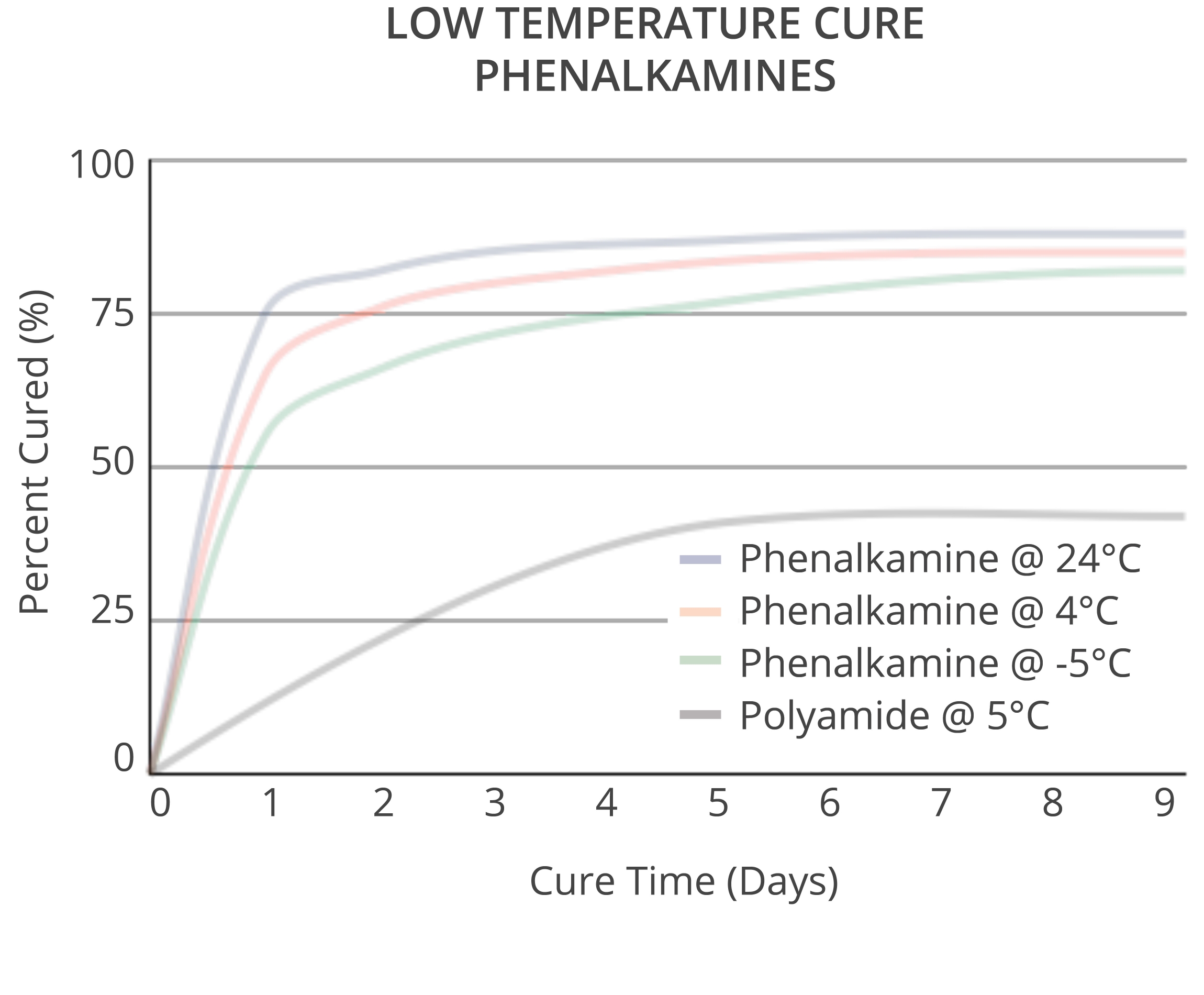

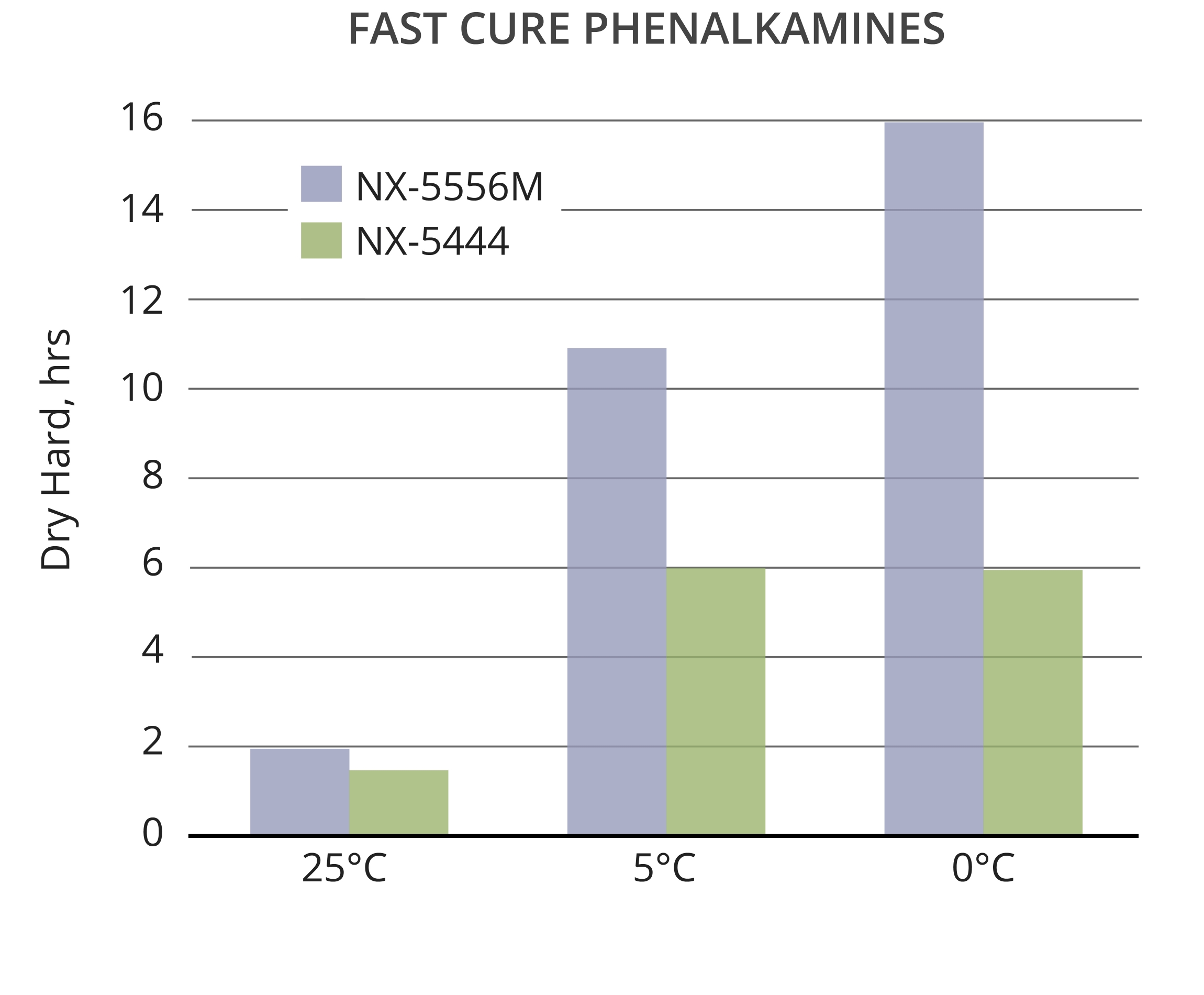

VERY FAST CURE AT LOW TEMPERATURES

Cardolite offers epoxy curing agents for primers, midcoats, top coats, and direct-to-metal coatings for year round applications. With a broad selection of chemistries and properties, Cardolite offers phenalkamine and phenalkamine adducts that cure very fast even at very low temperatures (below 0°C) and as a consequence, provide very good early water and immersion resistance. Moreover, our phenalkamides deliver faster cure speed than polyamides while maintaining long pot life. As another approach to low VOC, our NX-8000 Series waterborne curing agents also provide fast cure in conditions as challenging as 10°C and 80% relative humidity.

Our line of cardanol diluents act as an accelerator to epoxy-amine reactions in addition to increasing hydrophobicity of the system. They provide excellent corrosion protection despite being non-reactive and can be used as a replacement for nonyl phenol.

Cardolite CNSL-modified hydrocarbons are excellent options to improve intercoat adhesion and flexibility while maintaining fast cure and hardness development and good anticorrosion properties.

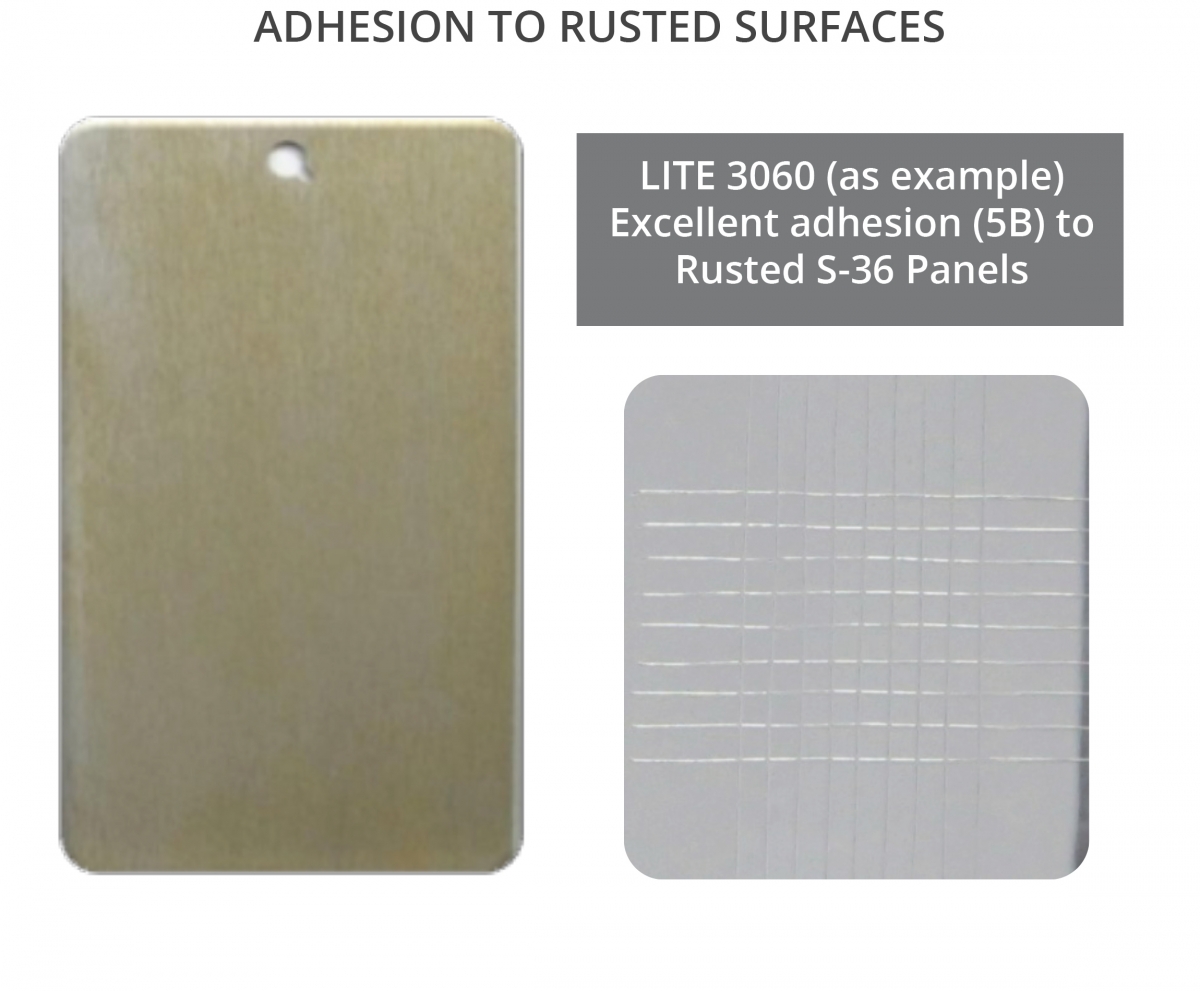

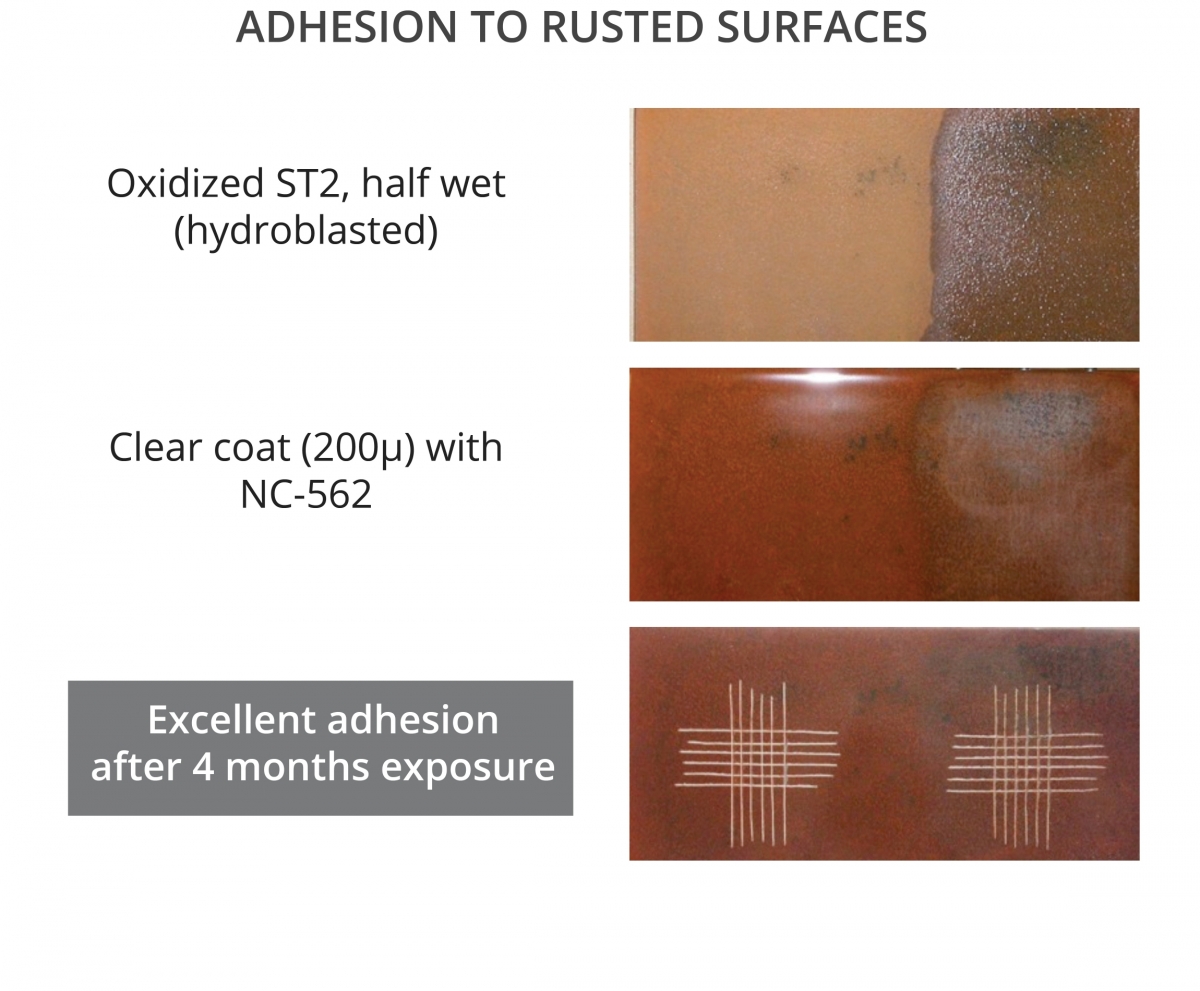

ADHESION TO UNPREPARED SUBSTRATES AND UNDERWATER

Cardolite’s CNSL curing agents are forgiving in nature. These products can adhere to surfaces that are not properly prepared due to rust or contamination. Some of our curing agents even cure under water as demonstrated by this video.

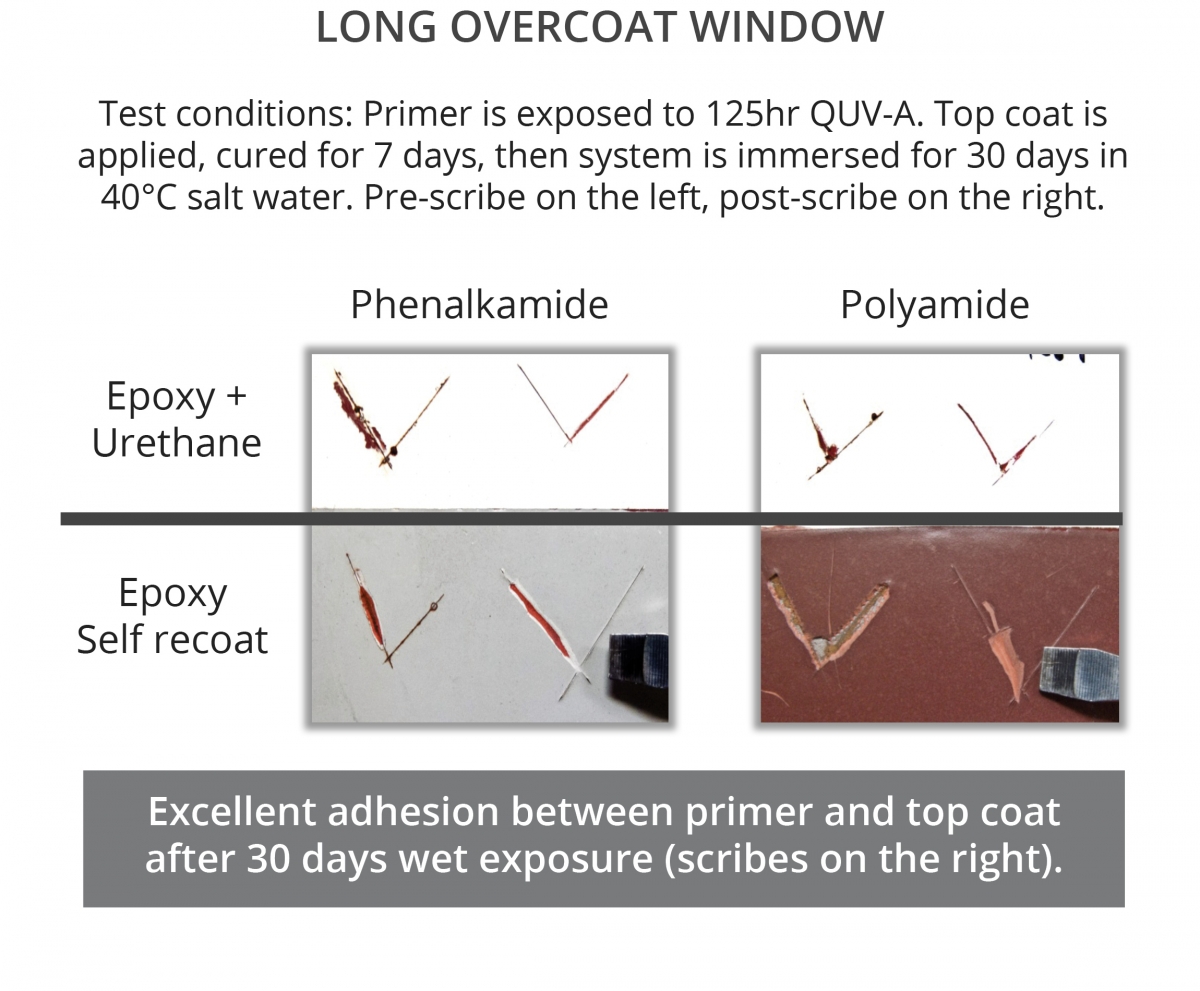

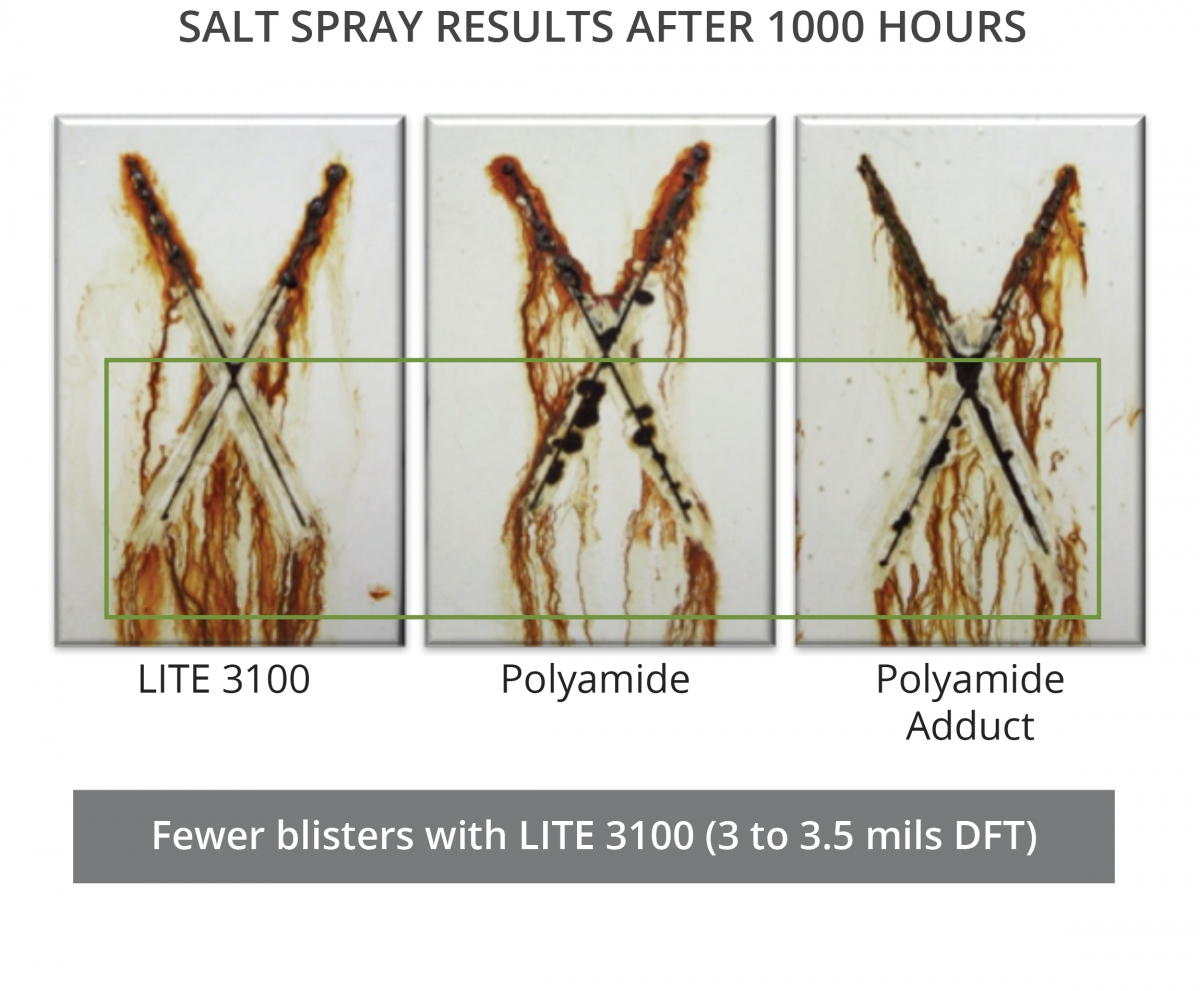

EXCELLENT CORROSION PROTECTION AND OVERCOAT WINDOW

Cardolite’s CNSL curing agents deliver excellent corrosion protection to coatings for immersed and atmospheric applications. They do such job without relying on expensive raw materials like anticorrosion pigments. Phenalkamines and phenalkamides inherited the hydrophobicity and therefore, outstanding water resistance of cardanol that coupled with the good adhesion to unprepared substrates and wetting properties result in excellent corrosion protection.

Moreover, these epoxy hardeners can be used at a broad range of mix ratios and protect surfaces even when applied in extreme temperature and humidity conditions. Phenalkamides in particular, also offer longer overcoat window which is very desirable for complex batch constructions such as off-shore platforms, ships, and windmills.

Cardolite’s cardanol derived epoxy diluents help ensure good corrosion performance while enabling low VOC coatings without hurting cure and barrier properties.

BETTER UV PROTECTION

Some epoxy coatings applications require good color stability. Cardolite offers very light color diluents and low yellowing curing agents designed to meet those needs. Please visit our industrial coatings market offering or select the technologies below for more information.