CNSL RESINS FOR RUBBER APPLICATIONS

Cardolite offers a wide variety of Cashew Nutshell Liquid (CNSL) derived resins for rubber applications. CNSL-based resins can substitute petroleum based phenolic resins as rubber modifiers to improve carbon footprint and lower toxicity of the final compound. CNSL resins can be used as tackifying resins and as plasticizers for polar and non polar rubber while providing additional benefits that could include antioxidant properties and adhesion improvement.

PLASTICIZER AND ANTIOXIDANT FOR ISOPRENE RUBBER

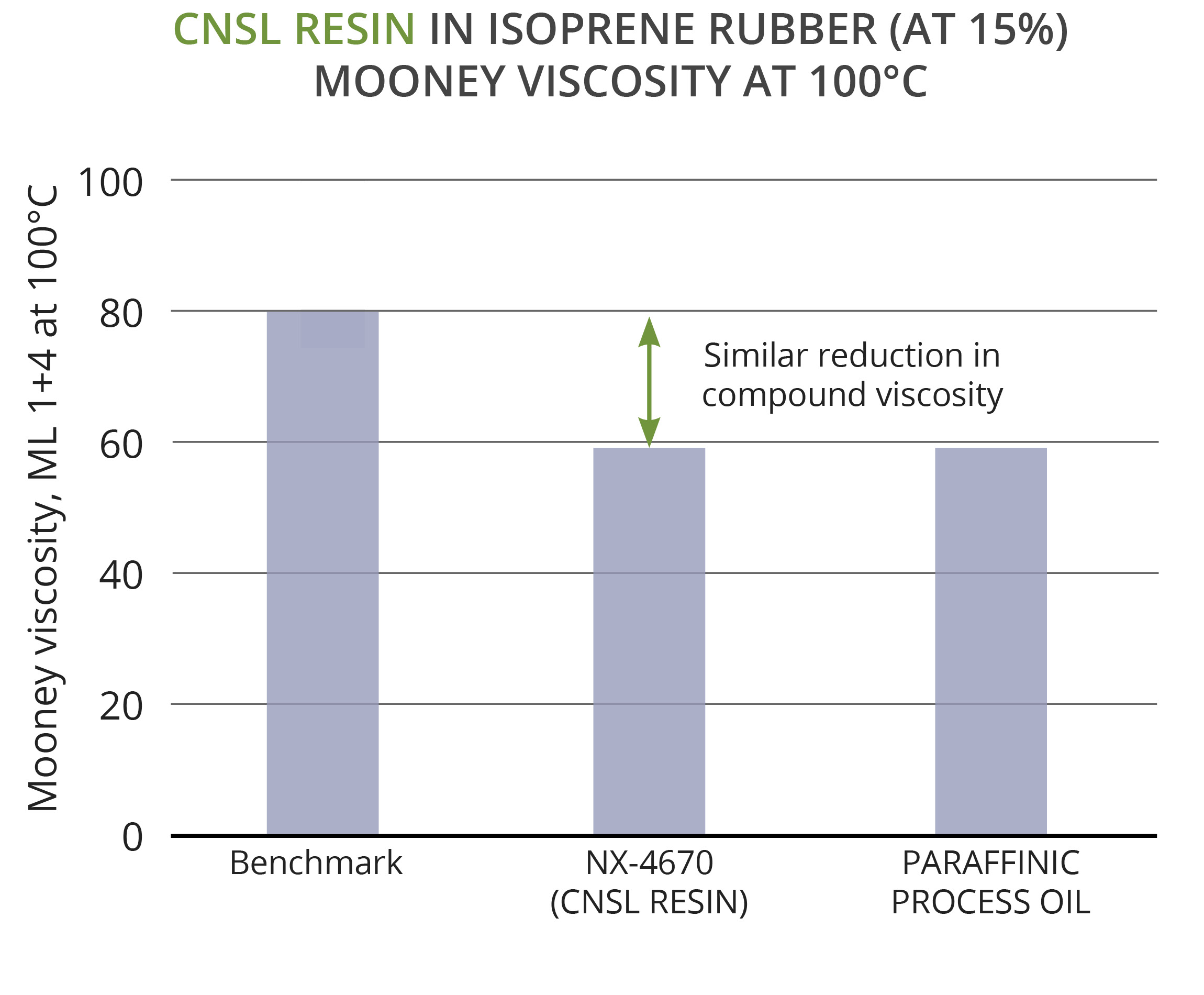

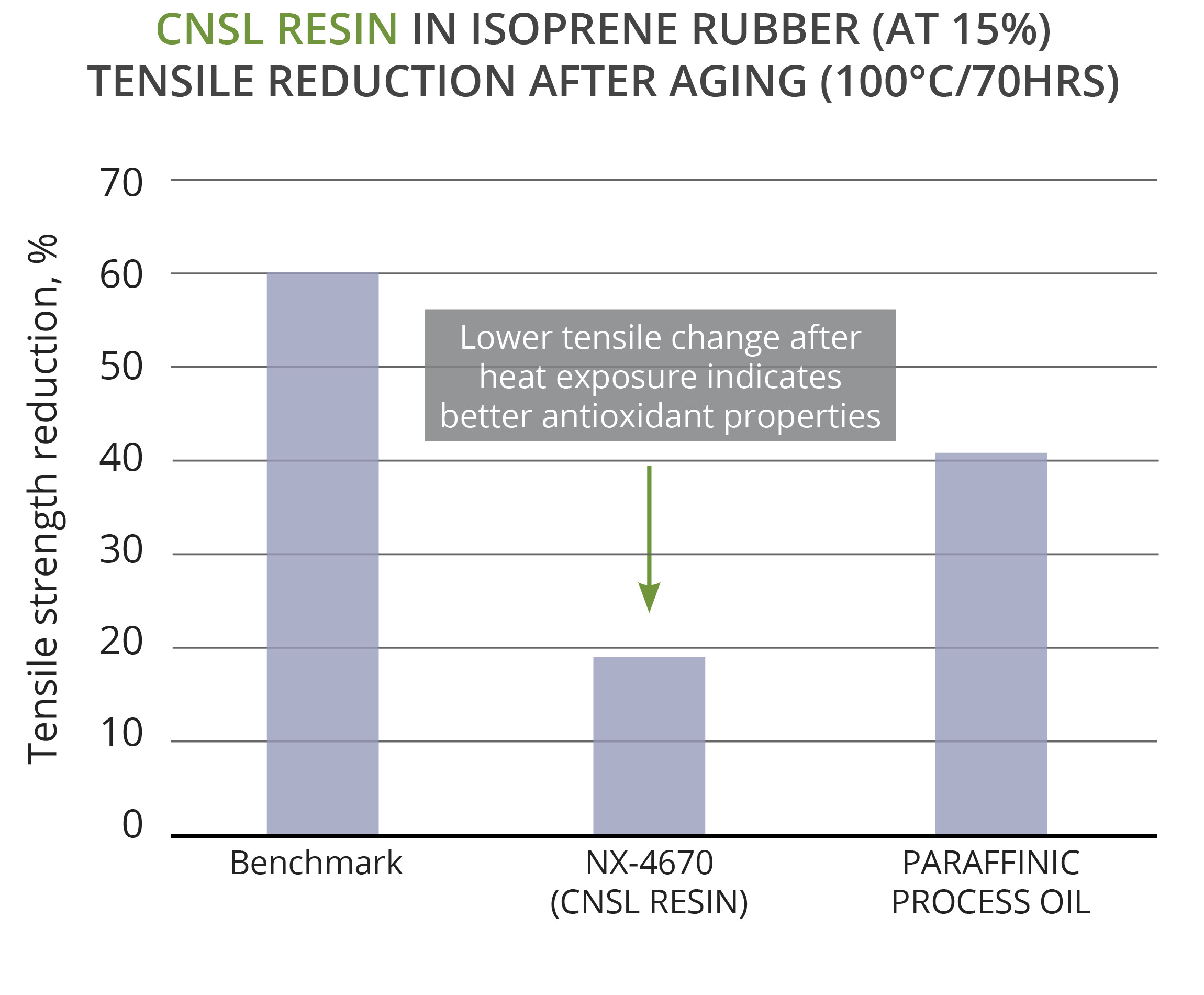

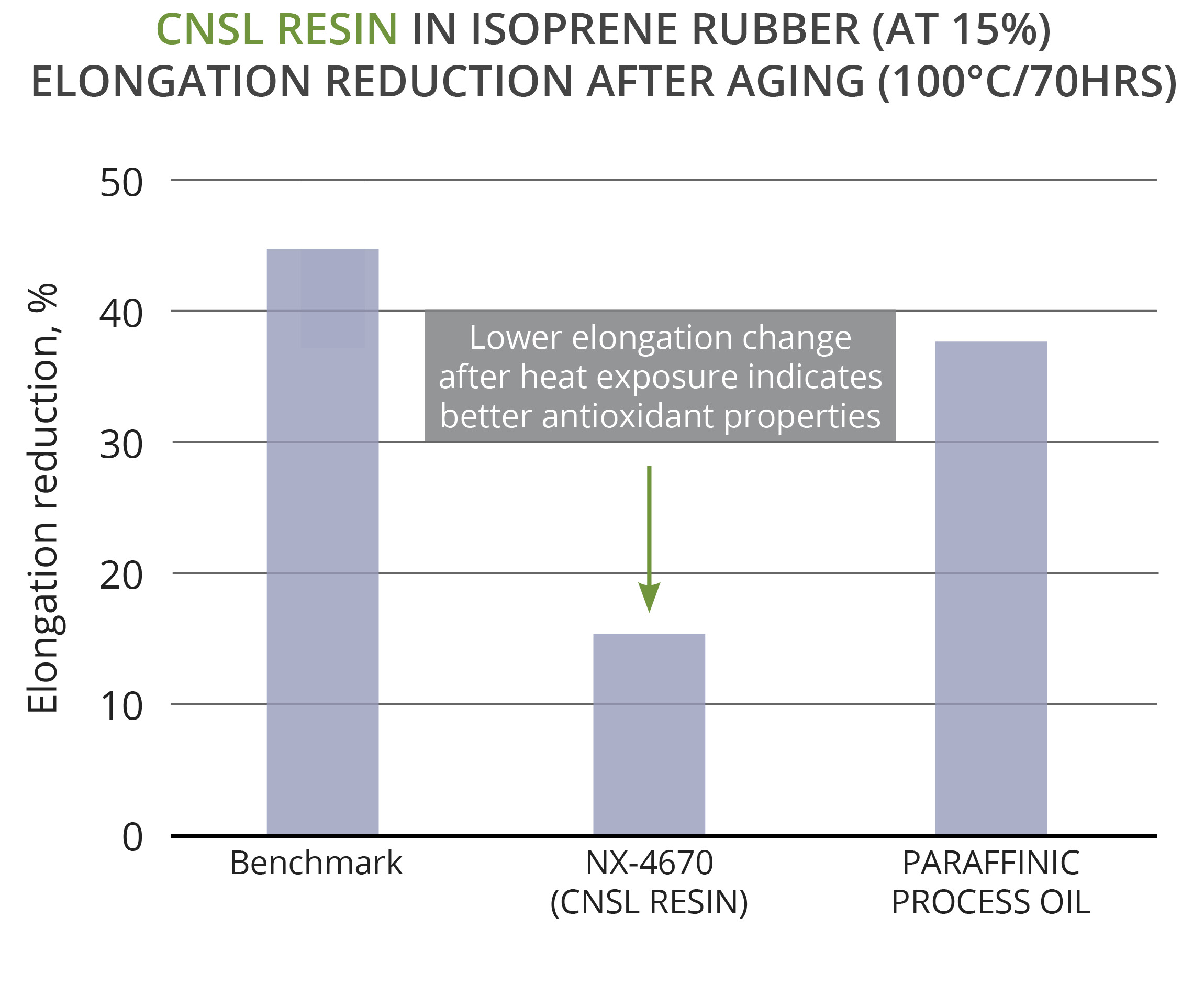

Cardolite CNSL-based phenolic resins can be formulated into synthetic natural rubber to act as plasticizers or process aids that also provide antioxidant properties. These higher molecular weight CNSL polymers are rubber modifiers that help reduce compound Mooney viscosity to similar levels to paraffinic process oils. Moreover, the incorporation of CNSL resins results in enhanced resistance to aging by heat as indicated by lower change in mechanical properties.

Adding Cashew Nutshell Liquid derived resins to rubber results in…

Lower compound viscosity and improved fluidity before vulcanization

Better antioxidant properties

Higher rubber hardness after vulcanization

Lower rubber modulus at high strain that can be adjusted by increased cure with little effect on elongation

PLASTICIZER AND RUBBER MODIFIER FOR NITRILE RUBBER (NBR)

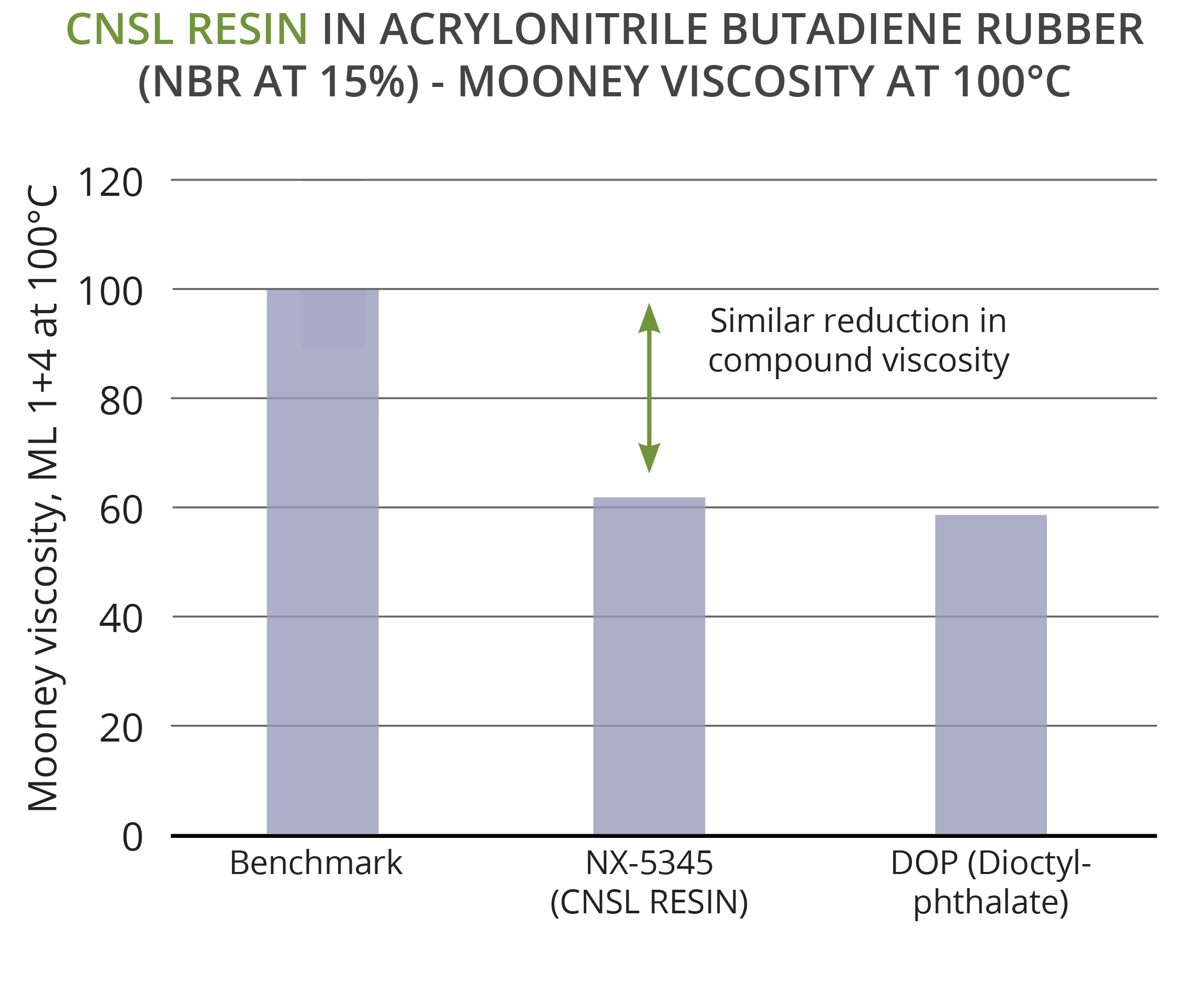

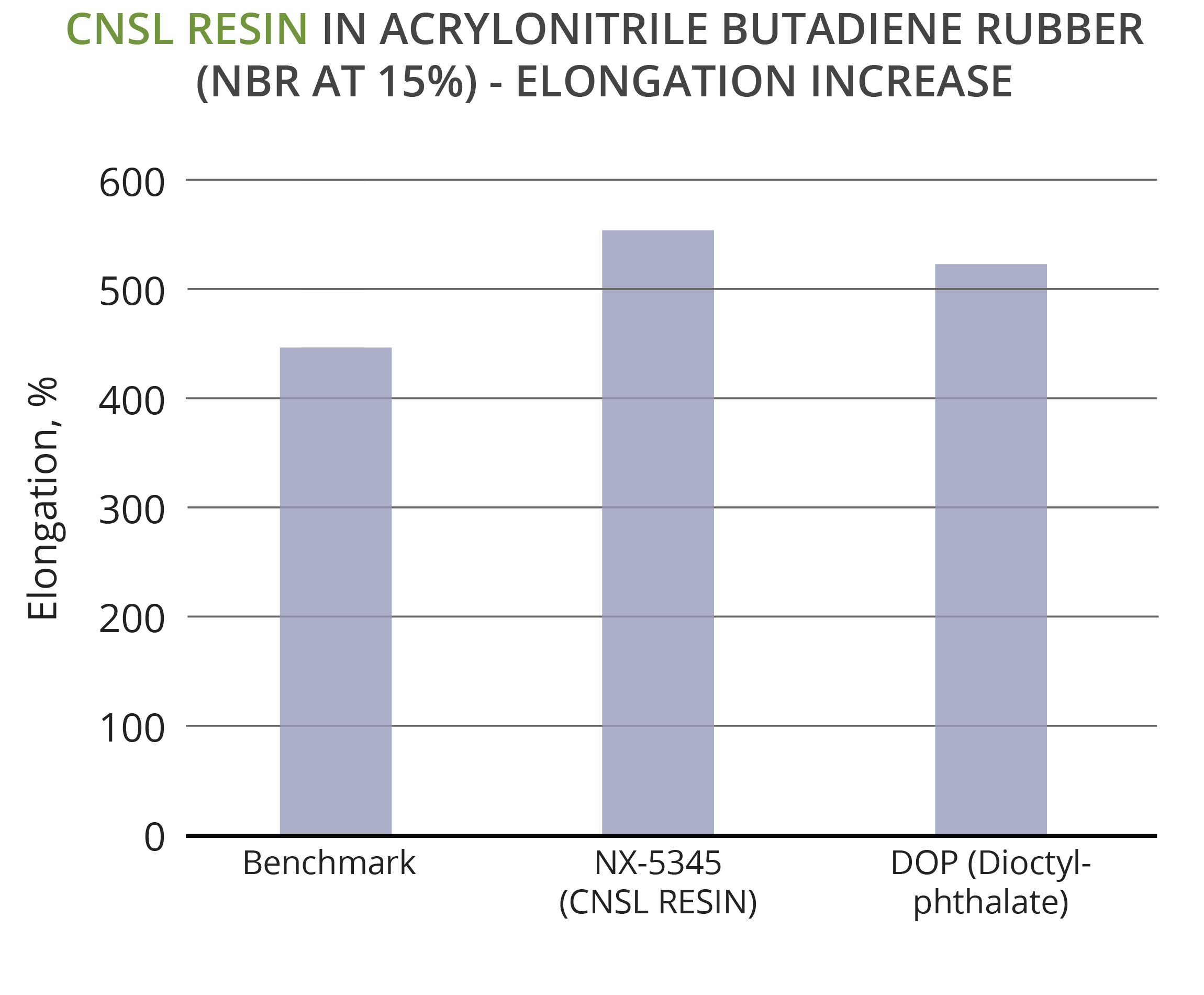

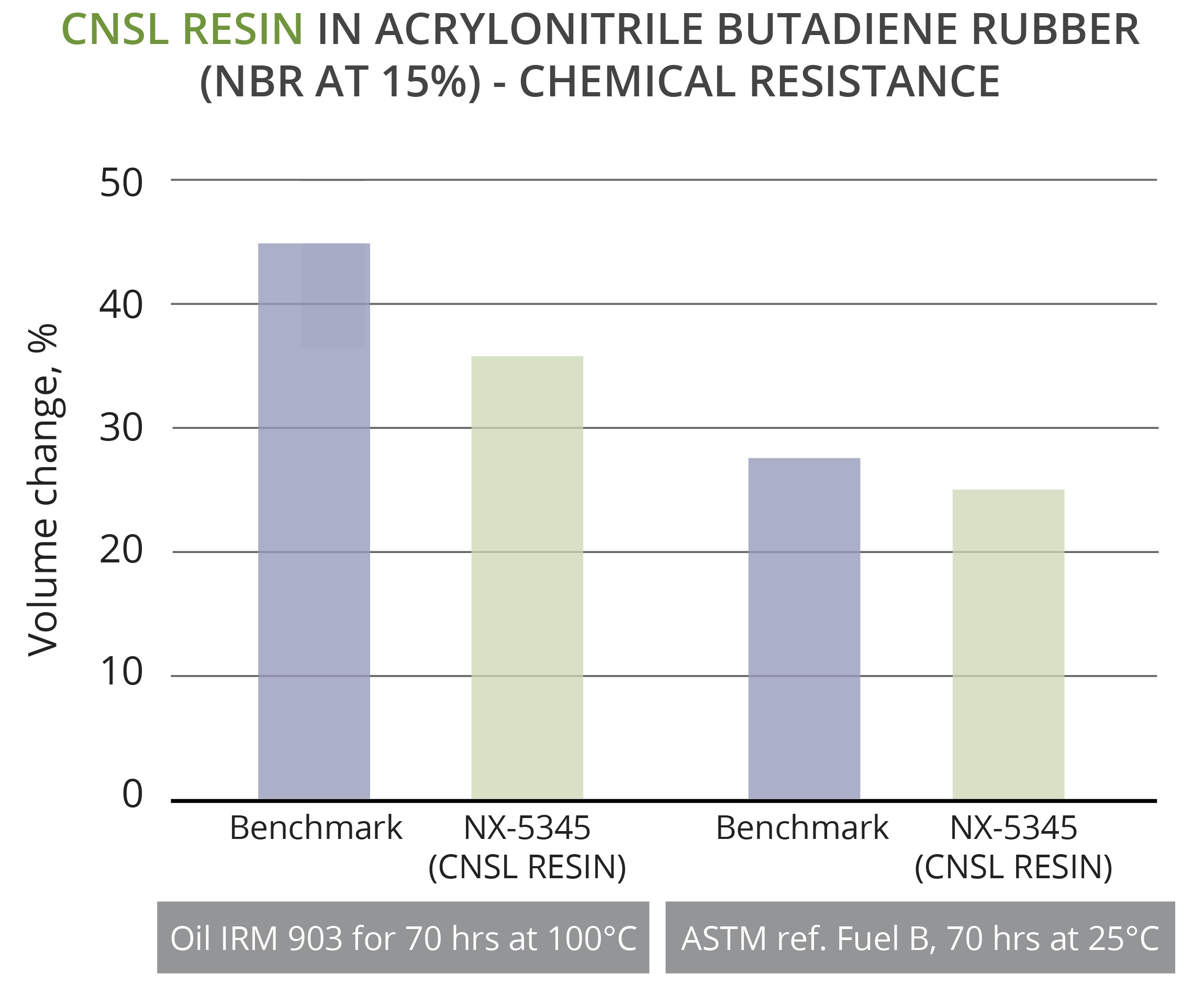

Cardolite CNSL-based phenolic resins are high bio-content plasticizer and rubber modifier alternatives for acrylonitrile butadiene rubber (or NBR). These renewable resins help lower compound viscosity and increase elongation due in part to the long aliphatic side chain inherited from CNSL. The unique structure of these resins enables rubbers to retain good elongation even after aging. As plasticizers, they show good resistance to brittleness even at lower temperatures. Moreover, the incorporation of CNSL resins reduces changes in volume upon exposure to certain chemicals compared to unmodified rubber.

Adding Cashew Nutshell Liquid derived resins to nitrile rubber results in…

Reduced compound viscosity and improved fluidity before vulcanization

Similar rubber hardness as when DOP and P6310 are incorporated

Better heat aging resistance, specially for elongation

Lower rubber low temperature brittleness

Improved and higher oil and fuel resistance than DOP and P6310

OUR OFFERING FOR RUBBER MATERIALS

The table below provides a list of CNSL resins in our offering that are recommended for use as rubber modifiers. For more information, please contact your sales representative or submit an inquiry on our site.

| CNSL Resin Grade | Viscosity (cPs) at 25°C | pH Value |

| NX-4670 | ≤ 12,000 | 10 – 12.1 |

| NC-360 | 32,000 – 42,000 | 10 – 12 |

| NC-370 | 25,000 – 80,000 (at 50°C) | 2 – 4 |

| NX-5341 | 40,000 – 51,000 | 2 – 4 |

| NX-5345 | 400 – 3,000 | 6 – 9 |

| NX-5205 | 25,000 – 40,000 | 8 – 12.5 |