Cardolite offers a unique line of cardanol-based epoxy resins, diluents, and modifiers that provide formulators with valuable tools to meet certain target properties. Cardolite portfolio is comprised of reactive and non-reactive diluents that not only lower viscosity, but also improve anti-corrosion properties, flexibility, and early water resistance. These cardanol-based diluents allow formulators to achieve performance and workability in zero and low VOC coatings and adhesives. In addition, we offer difunctional glycidyl ether resins and a polyglycidyl ether epoxy novolac to formulators that need to increase flexibility of the system without compromising barrier properties. Cardolite also offers non-CNSL monoglycidyl ethers as an option for formulations that can’t be changed to CNSL-based materials.

NON-REACTIVE DILUENTS

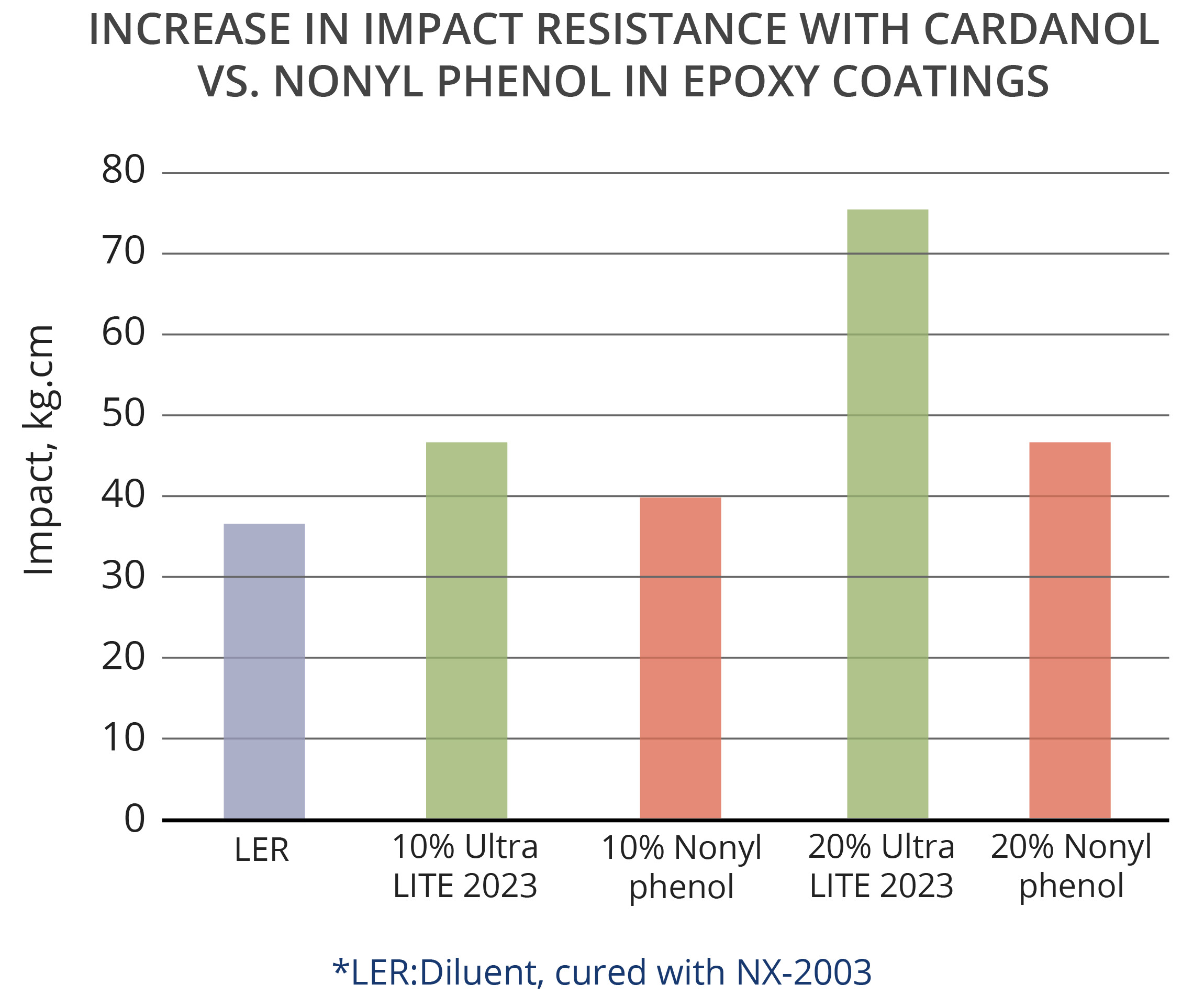

Cardolite’s line of cardanol-based non-reactive epoxy diluents are an effective way to reduce viscosity without the use of solvents. All cardanol derived grades carry the benefits of high hydrophobicity and therefore, excellent water resistance. Additionally, these diluents provide increased flexibility and impact resistance due to the long aliphatic chain in their backbone. Moreover, cardanol’s aromatic ring improves chemical resistance of those derivatives. Those combined properties help ensure our diluents have a positive effect on systems overall performance.

NON-REACTIVE DILUENTS TYPICAL PROPERTIES

| Product | Type | Color Gardner | Viscosity (cPs) | Documents |

|---|---|---|---|---|

| LITE 2020 | Non-reactive resin modifier | ≤ 14 | 30-115 | TDS MSDS (USA) MSDS (EU) |

| Ultra LITE 2020 | Non-reactive resin modifier | ≤ 2 | ≤ 115 | TDS MSDS (USA) MSDS (EU) |

| LITE 2100 | Hydrocarbon resin modifier | ≤ 4 | 450-750 | TDS MSDS (USA) MSDS (EU) |

| LITE 2100R | Hydrocarbon resin modifier | ≤ 4 | 500-1,000 | TDS MSDS (USA) MSDS (EU) |

| NX-2021 | Non-reactive resin modifier | ≤ 18 | 45-75 | TDS MSDS (USA) MSDS(EU) |

| NX-2022 | Non-reactive resin modifier | 5 - 8 | 40-60 | TDS MSDS (USA) MSDS (EU) |

| Ultra LITE 2023 | Non-reactive resin modifier | 1 | 40-100 | TDS MSDS (USA) MSDS (EU) |

| NX-2023 | Non-reactive resin modifier | ≤ 6 | 40-100 | TDS MSDS (USA) MSDS (EU) |

| NX-2023D | Non-reactive resin modifier | ≤ 15 | 80-140 | TDS MSDS (USA)MSDS (EU) |

| NX-2024 | Non-reactive resin modifier | 4 - 9 | 45-60 | TDS MSDS (USA) MSDS (EU) |

| NX-2025 | Non-reactive resin modifier | ≤ 5 | ≤ 60 | TDS MSDS (USA) MSDS (EU) |

| NX-2026 | Non-reactive resin modifier | ≤ 2 | ≤ 60 | TDS MSDS (USA) MSDS (EU) |

NX-202x Series

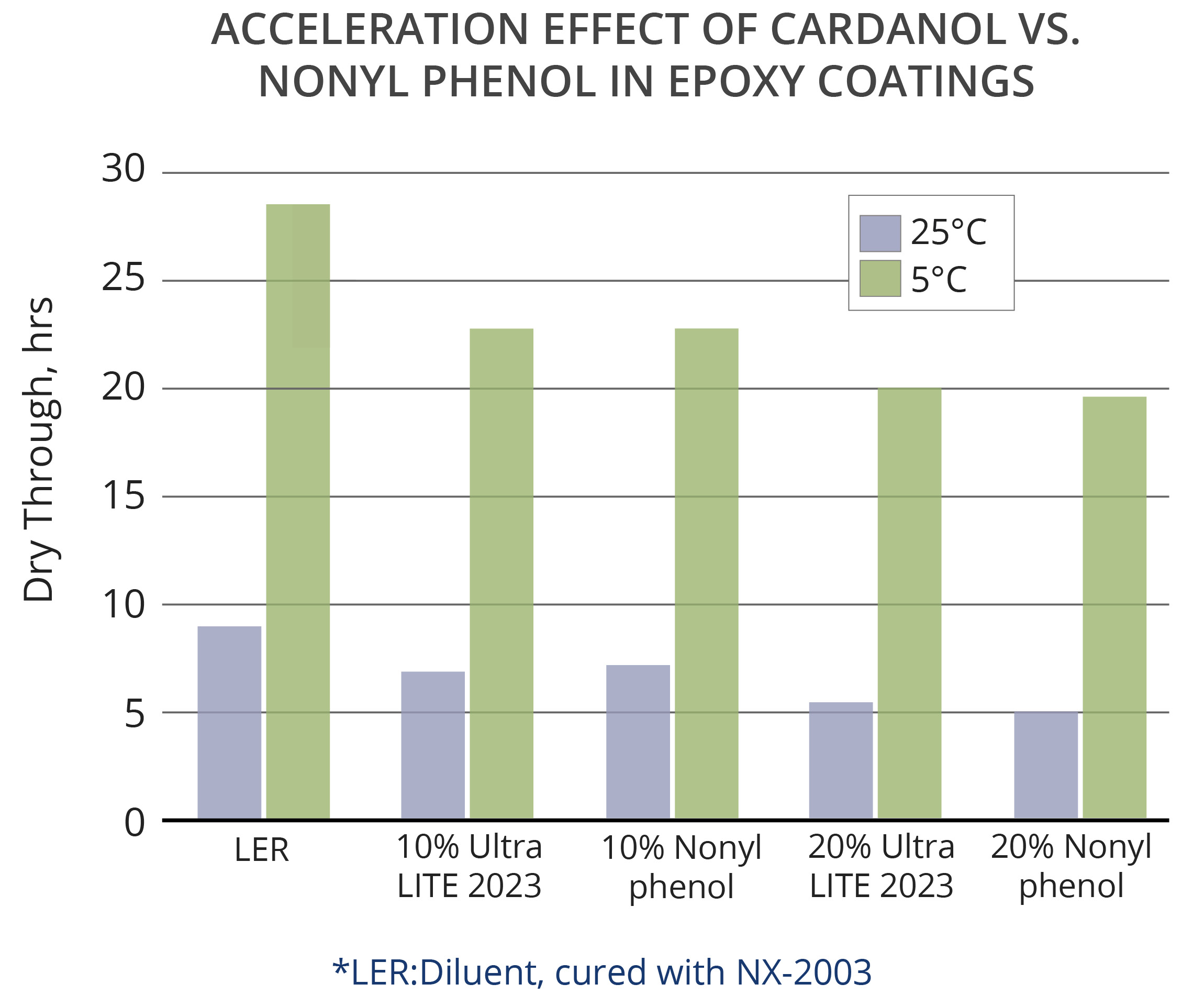

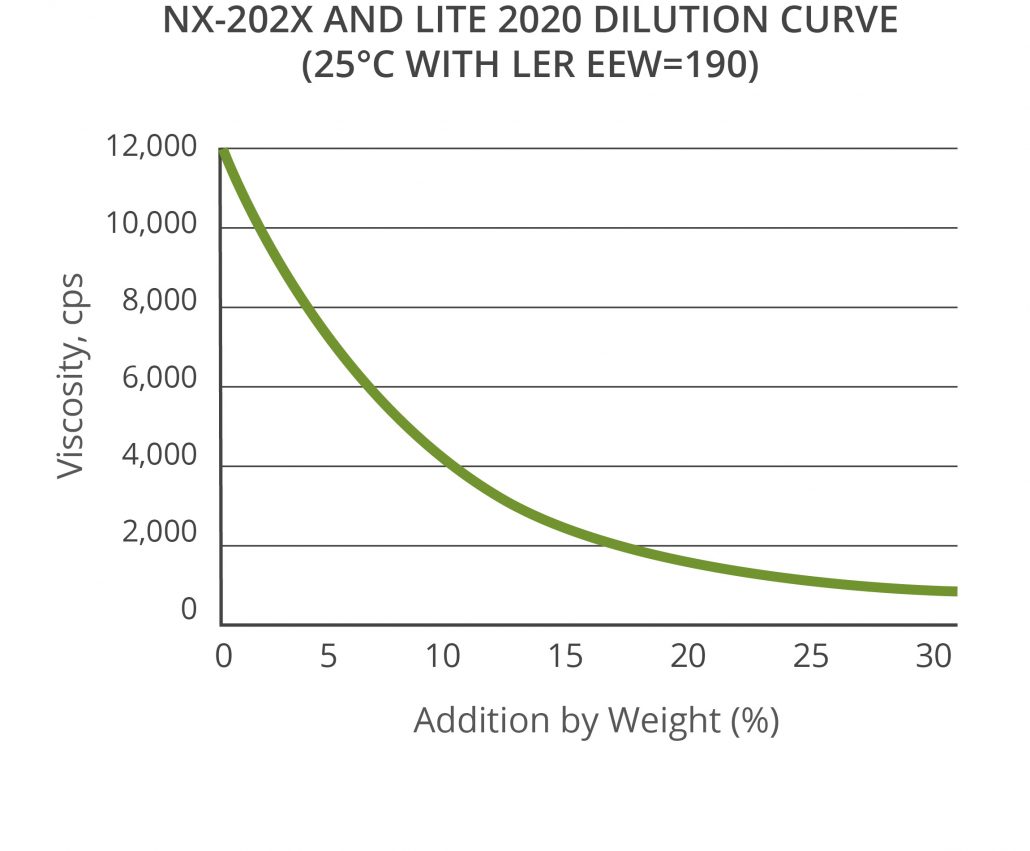

Cardolite NX-202x line represents various cardanol grades suitable for use as diluents and multipurpose resin modifiers in epoxy and polyurethane systems. Additionally, cardanol grades act as accelerators between epoxy resins and amines. Hence, they are suitable as nonyl phenol replacement. The long hydrophobic aliphatic side chain of the cardanol gives these products a very low viscosity and provides excellent water resistance and corrosion protection. Furthermore, these materials enable coatings and adhesive formulations to achieve higher solids without sacrificing other performance properties. NX-2021 is the standard modifier grade while NX-2022 is higher in purity. NX-2024 and NX-2025 are the lower odor and lighter initial color versions of NX-2021 and NX-2022, respectively. Ultra LITE 2023, NX-2023(D), and NX-2026 are the wet color stable versions of the NX-202x product family.

EXCELLENT DILUTION EFFICIENCY TO ENABLE LOW VOC COATINGS AND ADHESIVES

HYDROPHOBICITY AND AROMATICITY FOR BETTER WATER AND CHEMICAL RESISTANCE

INCREASED FLEXIBILITY AND IMPACT RESISTANCE

ULTRA LITE COLOR GRADES WITH LOW YELLOWING

NON-TOXIC ALTERNATIVE TO NONYL PHENOL WITH SIMILAR PERFORMANCE

Ultra LITE 2020 Series

Cardolite LITE 2020 and Ultra LITE 2020 are mono-ethoxylated cardanol materials suitable for use as diluents and multipurpose resin modifiers in epoxy and polyurethane systems. These resins are ideal for formulating environmentally friendly epoxy and polyurethane high solids or solvent free coatings and adhesives. Due to their unique chemical structure, they are more efficient than traditional hydrocarbon resins in reducing viscosity and provide good wetting properties. Their hydrophobic nature allows for good corrosion resistance and early water resistance. Differently from cardanol grades, the 2020 family helps lengthen gel time of resin systems. Ultra LITE 2020 is a lower color version

of LITE 2020.

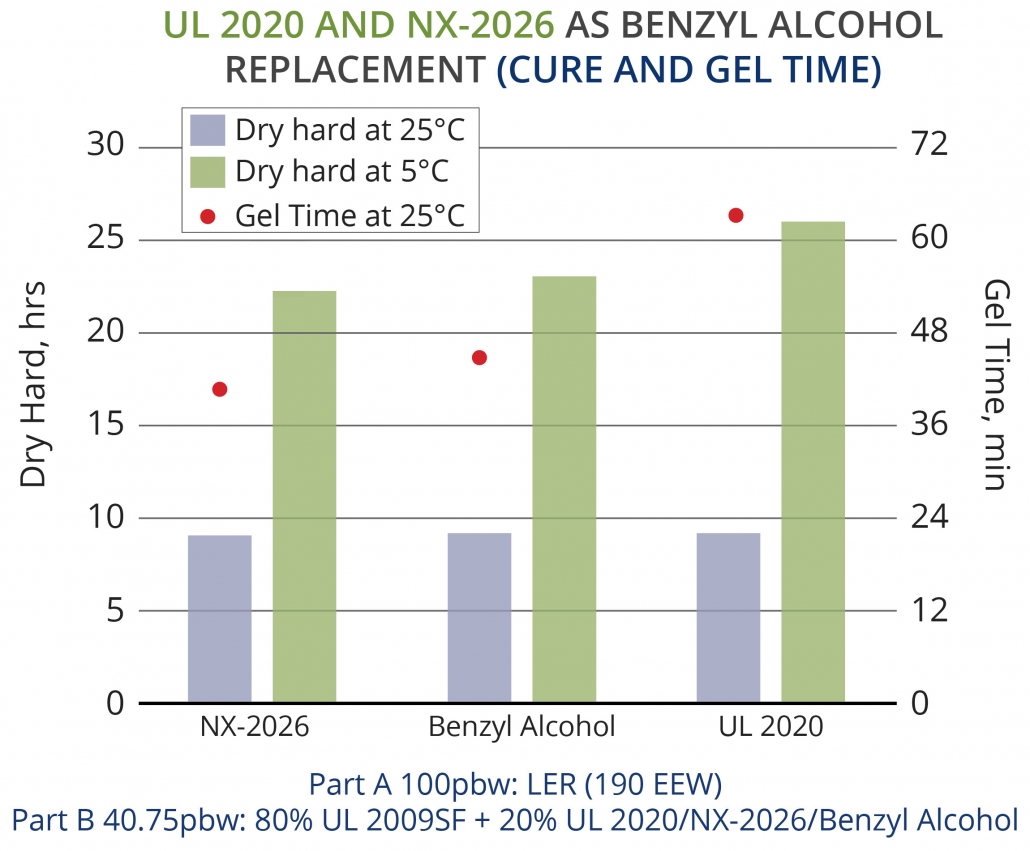

Ultra LITE color cardanol grade, NX-2026, and Ultra LITE 2020 (UL 2020) can be excellent renewable and lower volatile alternatives to Benzyl Alcohol with appropriate adjustments in formulations to account for viscosity and cure properties differences. The graph on this page shows a comparison of dry hard times and gel times between benzyl alcohol, UL 2020, and NX-2026 as reference.

Cardolite LITE 2100(R) are low color and low viscosity CNSL modified hydrocarbon resins. They are designed to enable high solids and solvent free formulations by lowering the viscosity of epoxy resins more efficiently than typical phenol based hydrocarbon resins and by improving overall system compatibility for better film formation. These products show good hardness development while providing improved flexibility and impact resistance. Their high hydrophobicity results in excellent water resistance, and more importantly, excellent corrosion protection on immersed and vapor exposed surfaces. Both products show very good UV resistance with excellent gloss retention for use in lighter color coatings.

REACTIVE DILUENTS

Cardolite’s reactive diluent line is comprised of CNSL-based mono-functional epoxy diluents (NC-513 family) and multi-functional diluent (LITE 513DF). Both lines provide the intrinsic benefits of CNSL technology such as high levels of hydrophobicity, flexibility and aromaticity while efficiently lowering the viscosity of epoxy systems. Their epoxy functionality ensures better cross linking density and overall performance and durability. A line of non-CNSL light color mono-functional epoxy diluents is also available.

REACTIVE DILUENTS TYPICAL PROPERTIES

| Product | Type | Color Gardner | Viscosity (cPs) | EEW | HyCl (%) | Documents |

|---|---|---|---|---|---|---|

| NC-513 | Monofunctional reactive diluent | 9 | 40-70 | 425-575 | ≤ 2 | TDS MSDS (USA) MSDS (EU) |

| LITE 513E | Monofunctional reactive diluent | 5 | 20-40 | 360-410 | ≤ 1000ppm total Cl | TDS MSDS (USA) MSDS (EU) |

| Ultra LITE 513 | Monofunctional reactive diluent | 1 | 20-35 | 350-425 | ≤ 0.5 | TDS MSDS (USA) MSDS (EU) |

| LITE 513DF | Multifunctional reactive diluent | < 6 | 90-200 | 250-300 | TDS MSDS (USA) | |

| NT-3000 | C12-14 Reactive diluent | ≤ 50 (APHA) | 5-10 | 275-300 | na | TDS MSDS (USA) MSDS (EU) |

| NT-3009 | C12-13 Reactive diluent | ≤ 0.5 | 5-15 | 270-300 | na | TDS MSDS (USA) |

Ultra LITE 513 Series

The Ultra LITE 513 family consists of monofunctional epoxy diluents that efficiently lower viscosity and can be excellent alternatives to traditional glycidyl ethers. NC-513 is the standard grade. Ultra LITE 513 (UL 513) is a higher purity, lower viscosity, very light color version of NC-513. LITE 513E is a very low total chlorine version of NC-513 suitable for electronic applications.

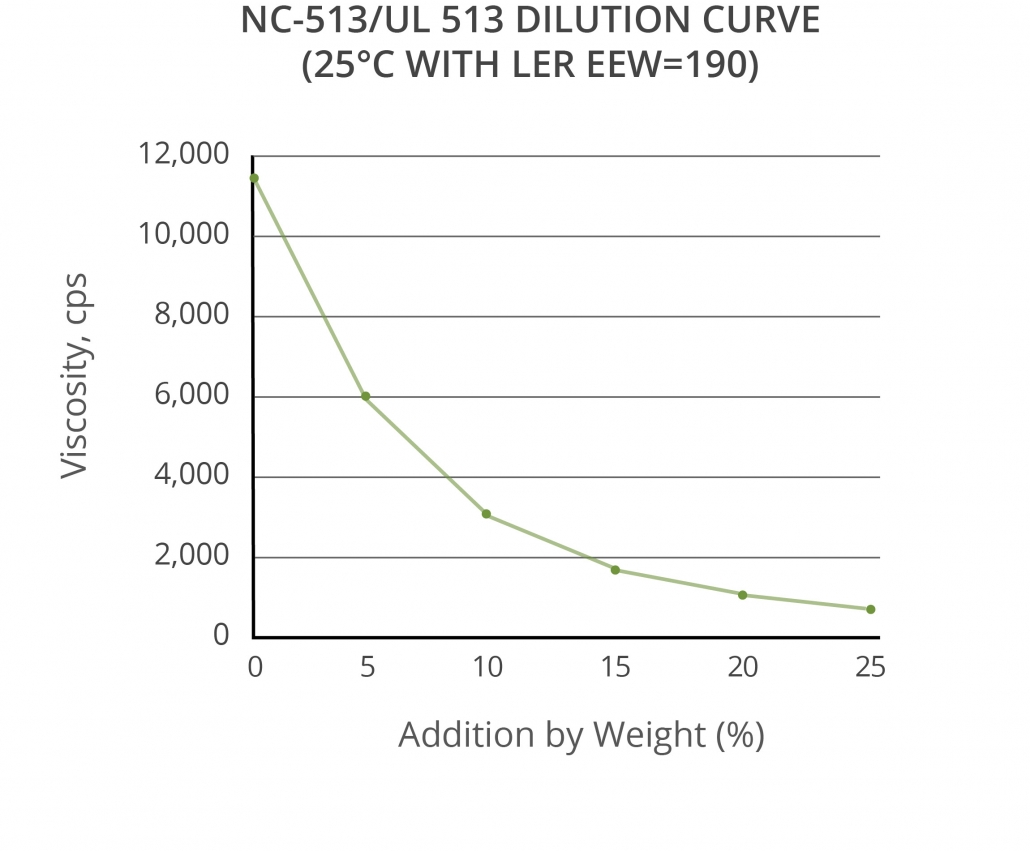

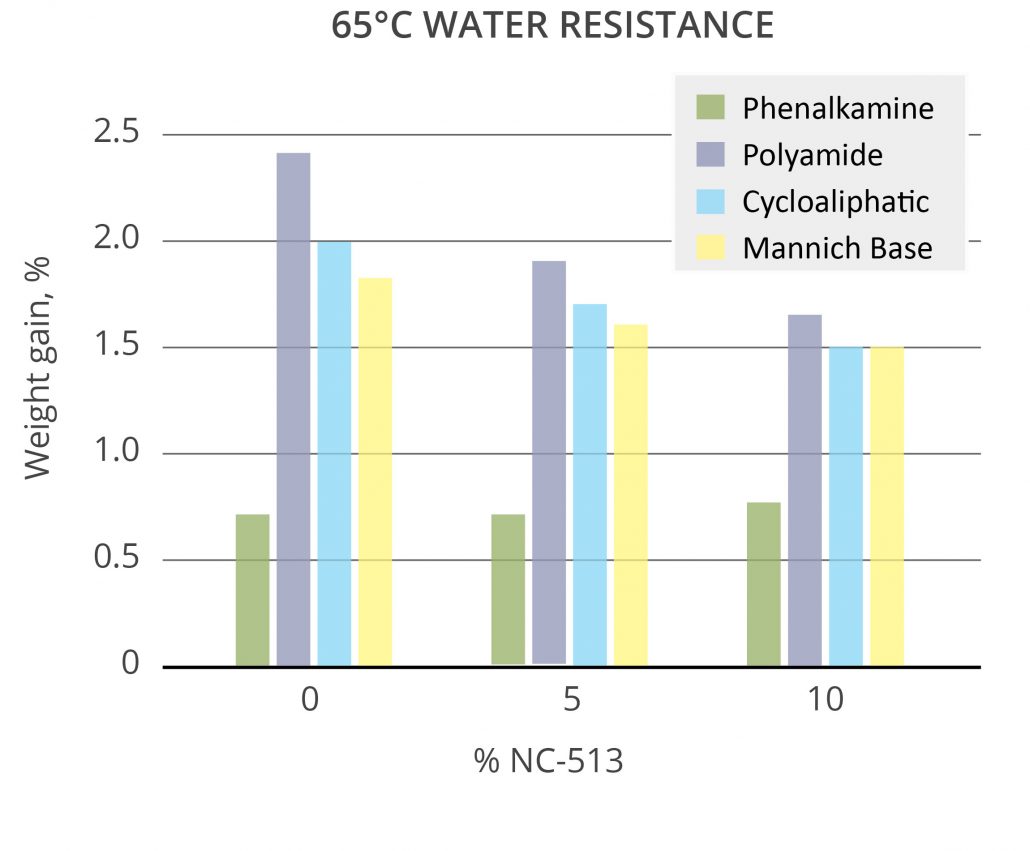

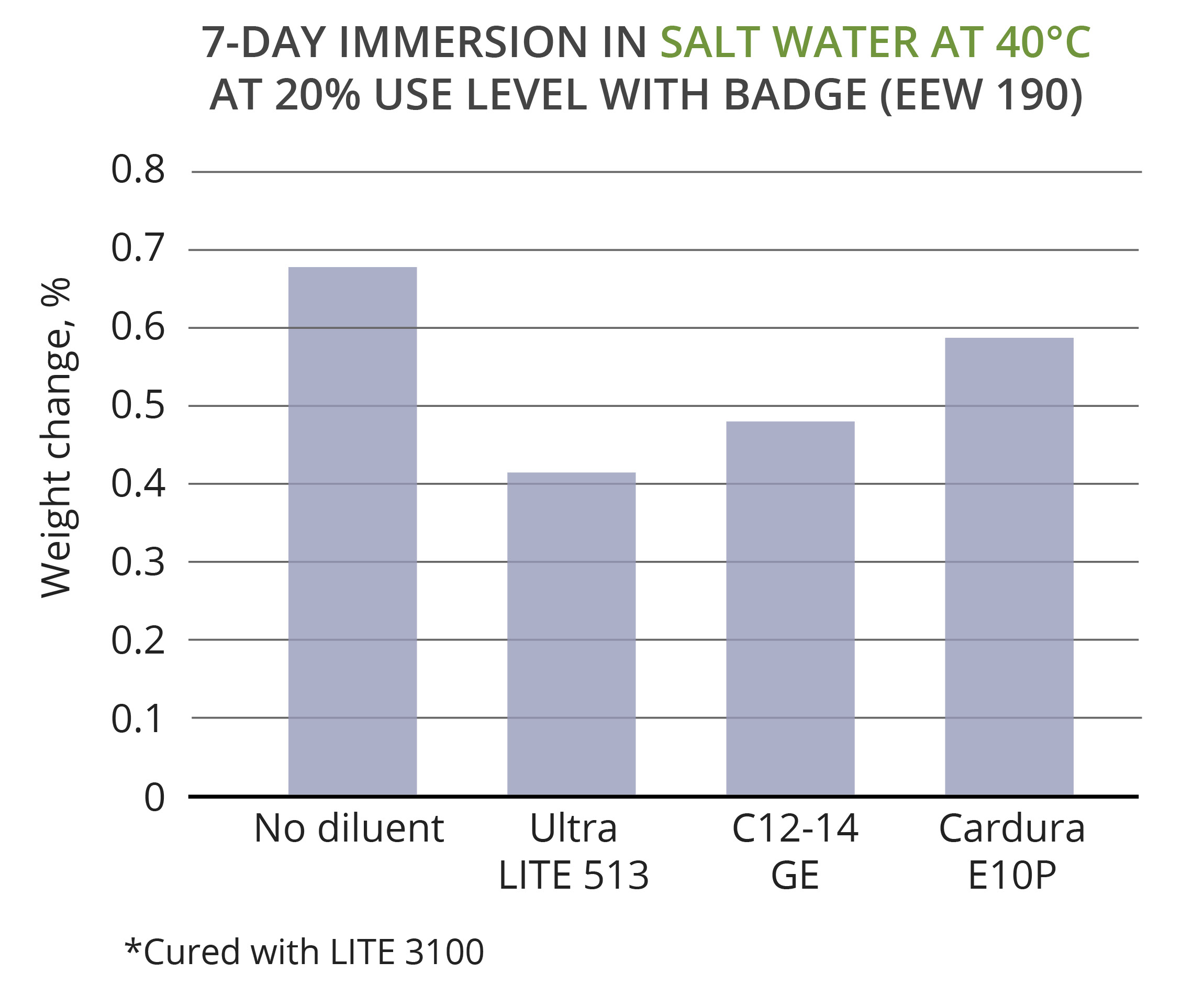

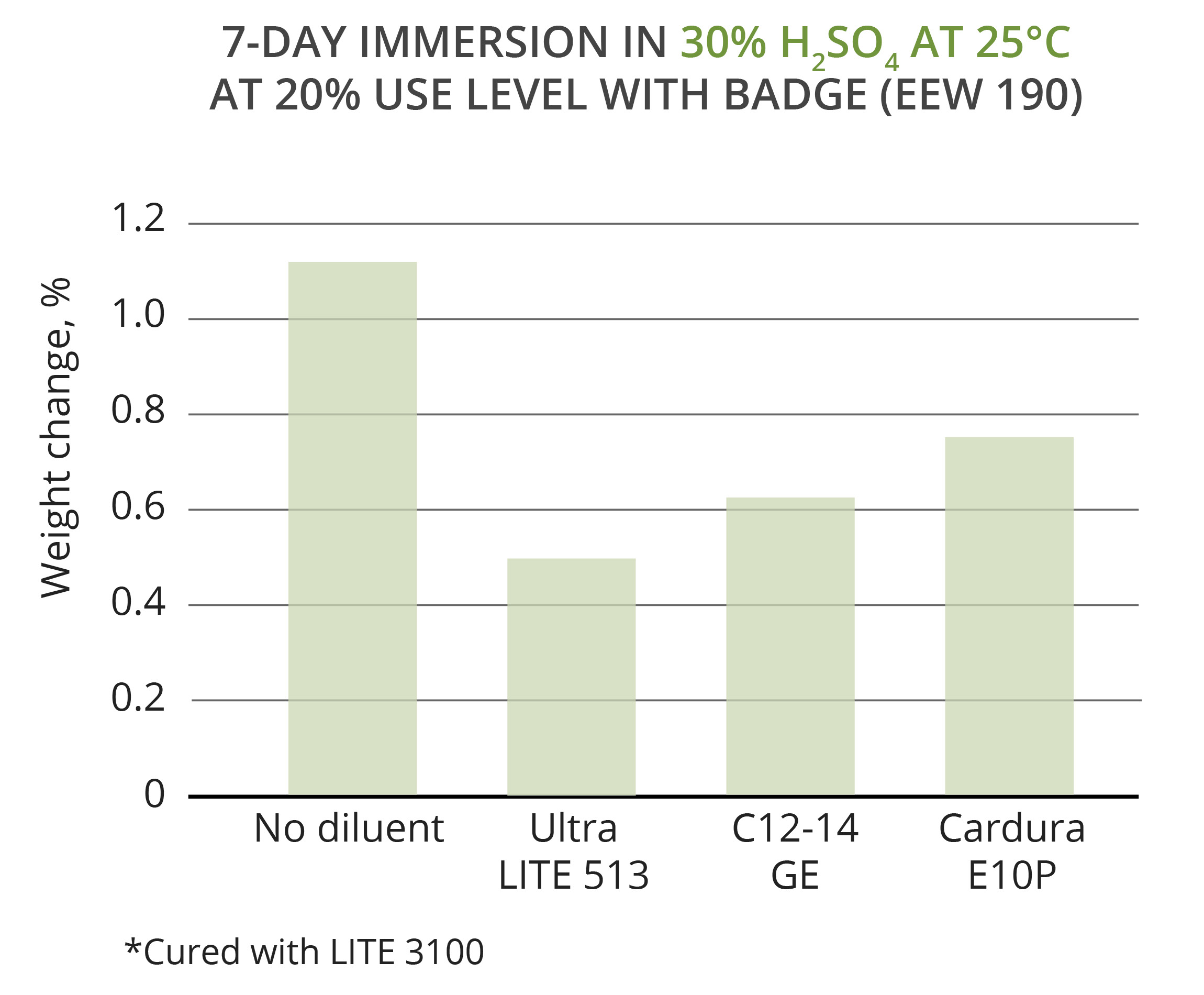

This line of cardanol-based reactive diluents is incorporated in the polymer network to minimize any effects on barrier protection. In addition, the good hydrophobicity, aromaticity (chemical and thermal resistance), and flexibility inherited from the cardanol backbone ensures good performance of the final epoxy system. The performance data shown on this page illustrates how the addition of NC-513/UL 513 to liquid epoxy resin systems improves water resistance (lower weight gains) at high temperature. Moreover, NC-513/UL 513 show better resistance to acid and salt water solutions than competitive C12-C14 GE and Cardura E10P diluents.

LITE 513DF – NEW HIGH STRENGTH DILUENT

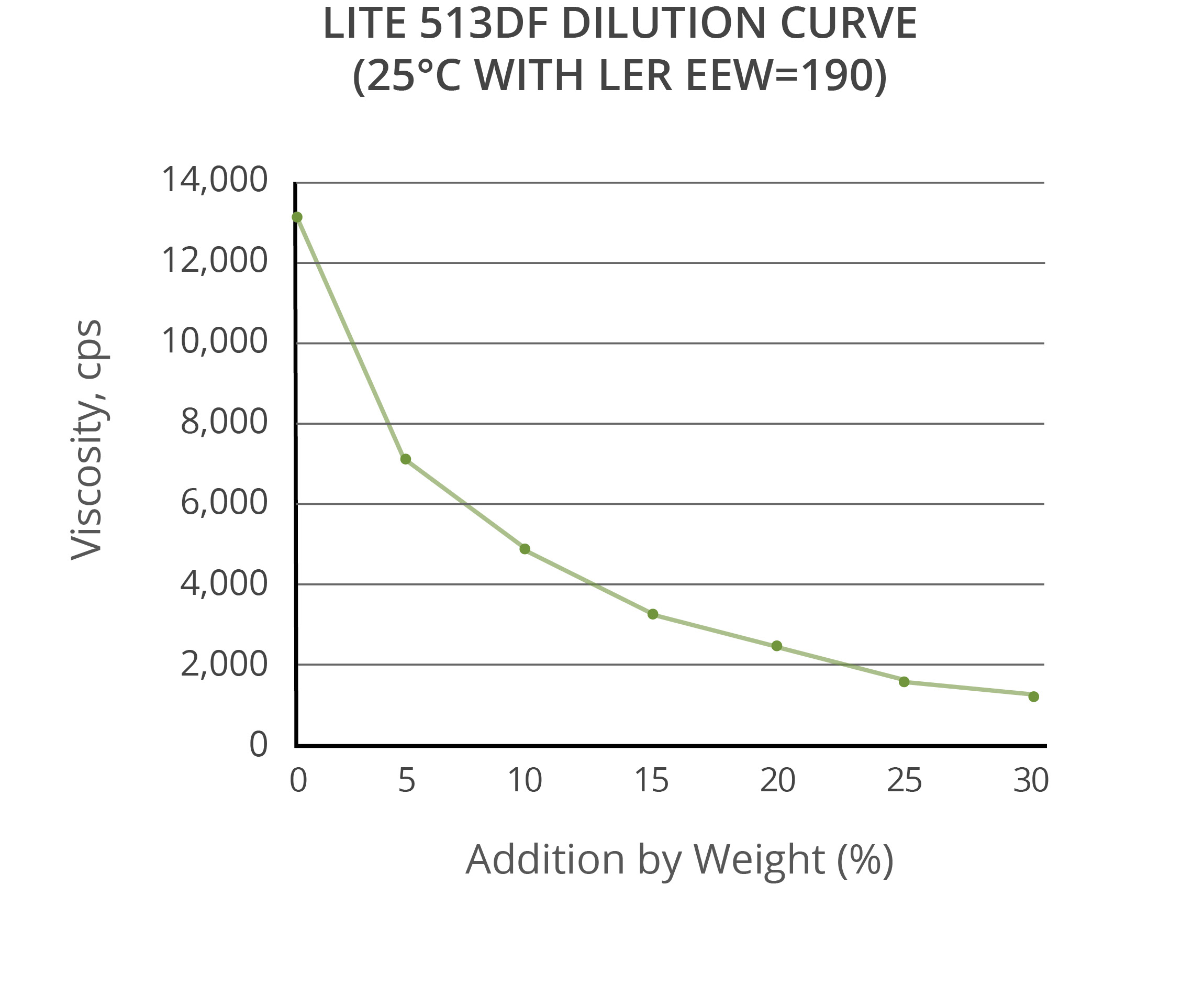

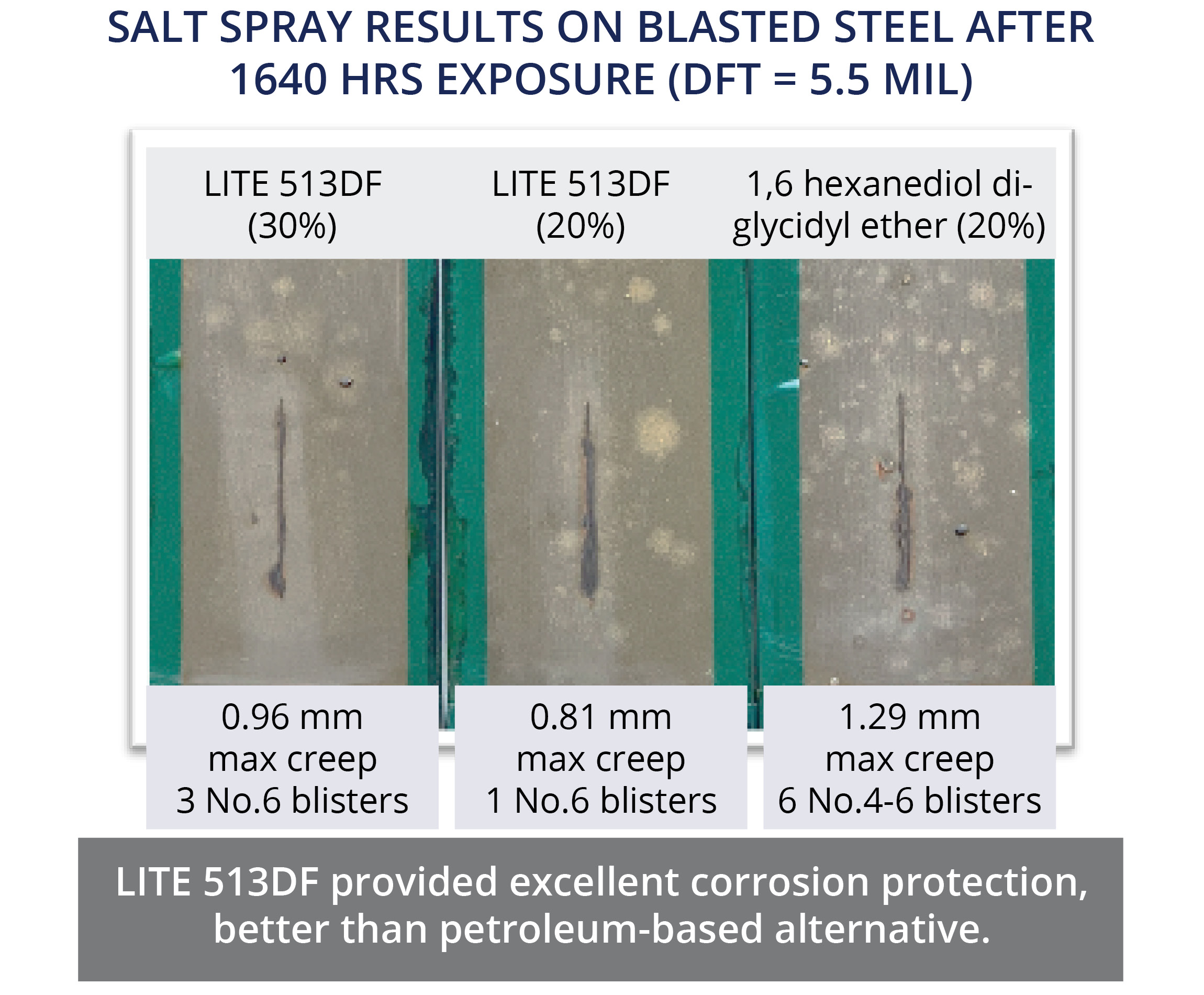

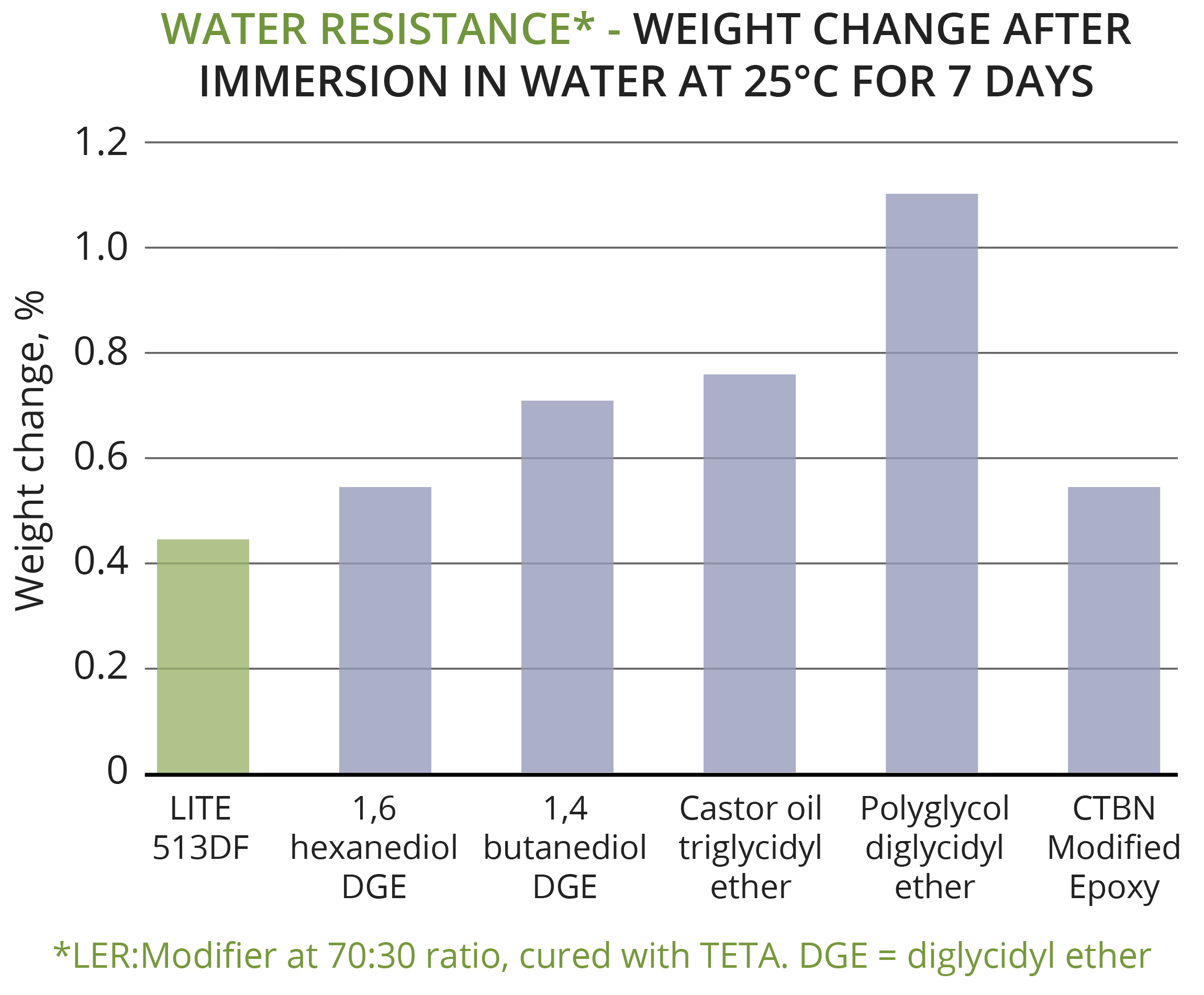

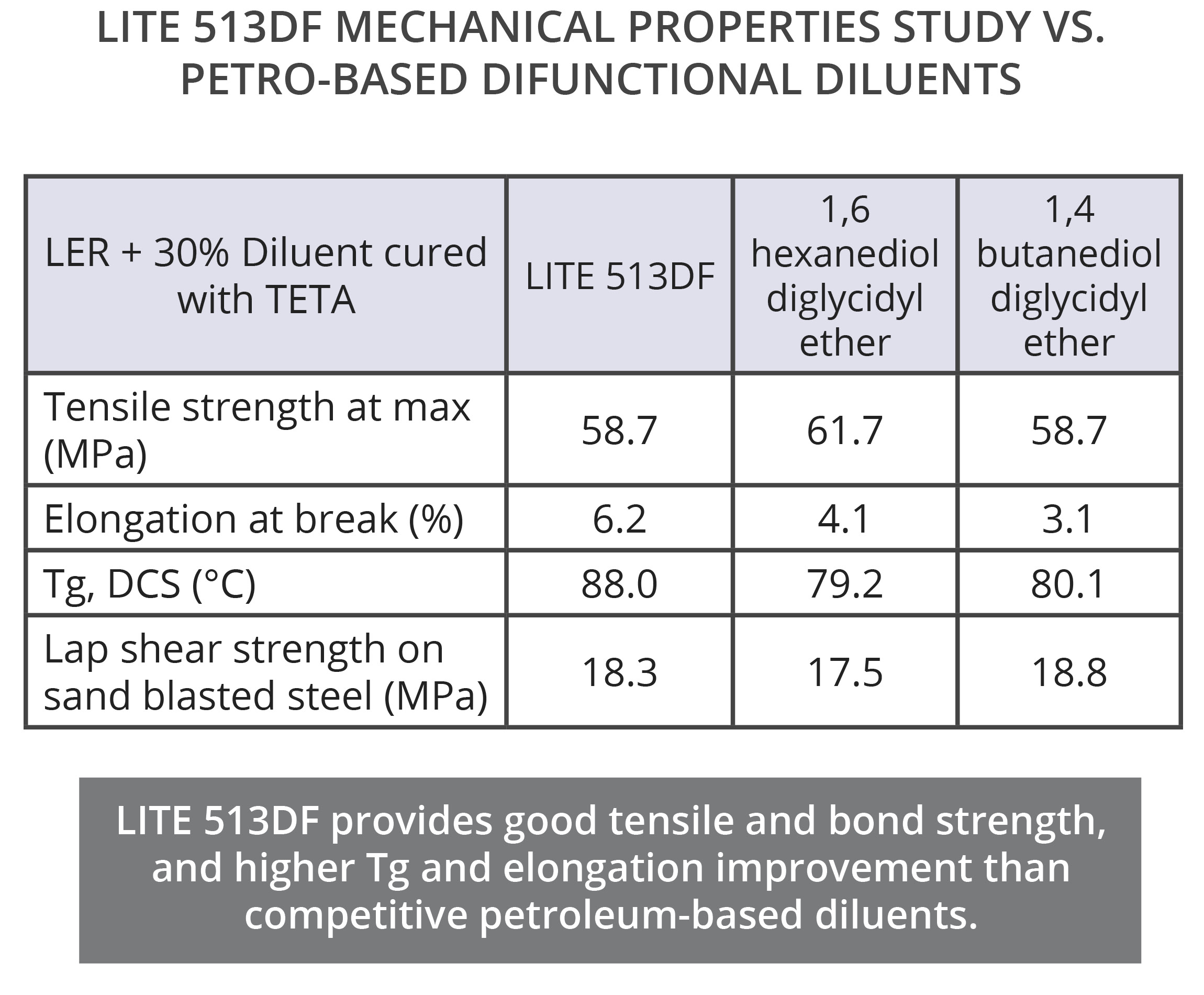

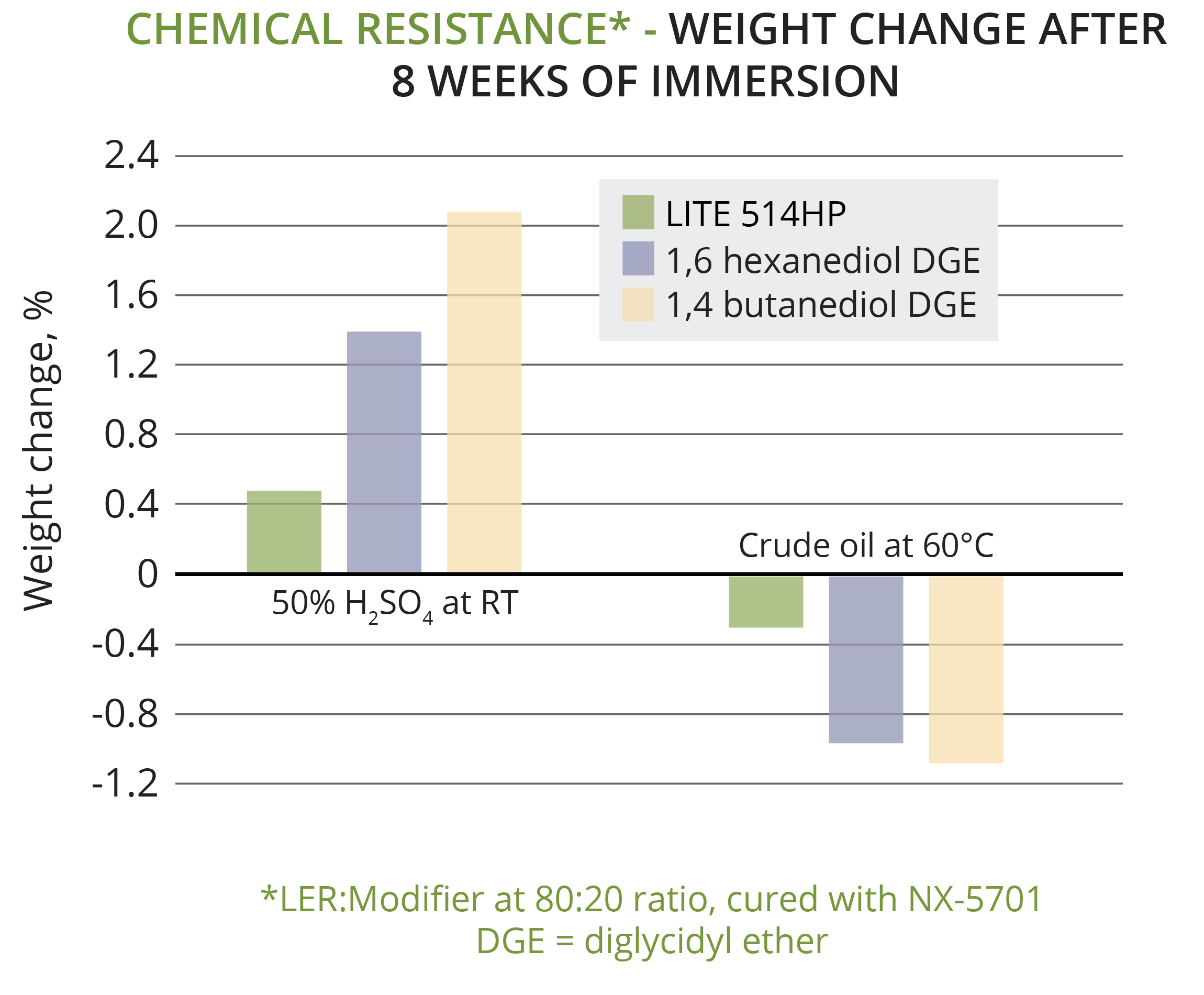

LITE 513DF is a new CNSL-based, high bio-content diluent with lower epoxy equivalent weight than standard 513. This material is suitable for epoxy systems such as coatings, one- and two- component adhesives and composites. LITE 513DF is low in viscosity and provides excellent dilution power as indicated by the addition by weight curve with bisphenol A type liquid epoxy resin. As a diluent, it provides good hardness development at ambient and low temperatures. Similar to other CNSL-based materials, LITE 513DF displays good water resistance and flexibility. In coatings applications, LITE 513DF has demonstrated very good corrosion protection properties in long-term salt sprays tests as shown by the pictures of exposed panels on this page. In adhesive applications, this epoxy functional diluent also acts as a modifier that increases elongation and bond strength while minimizing effect on Tg and tensile strength.

This material is an excellent alternative to petroleum-based difunctional diluents (e.g., 1,6 hexanediol diglycidyl ether and 1,4 butanediol diglycidyl ether).

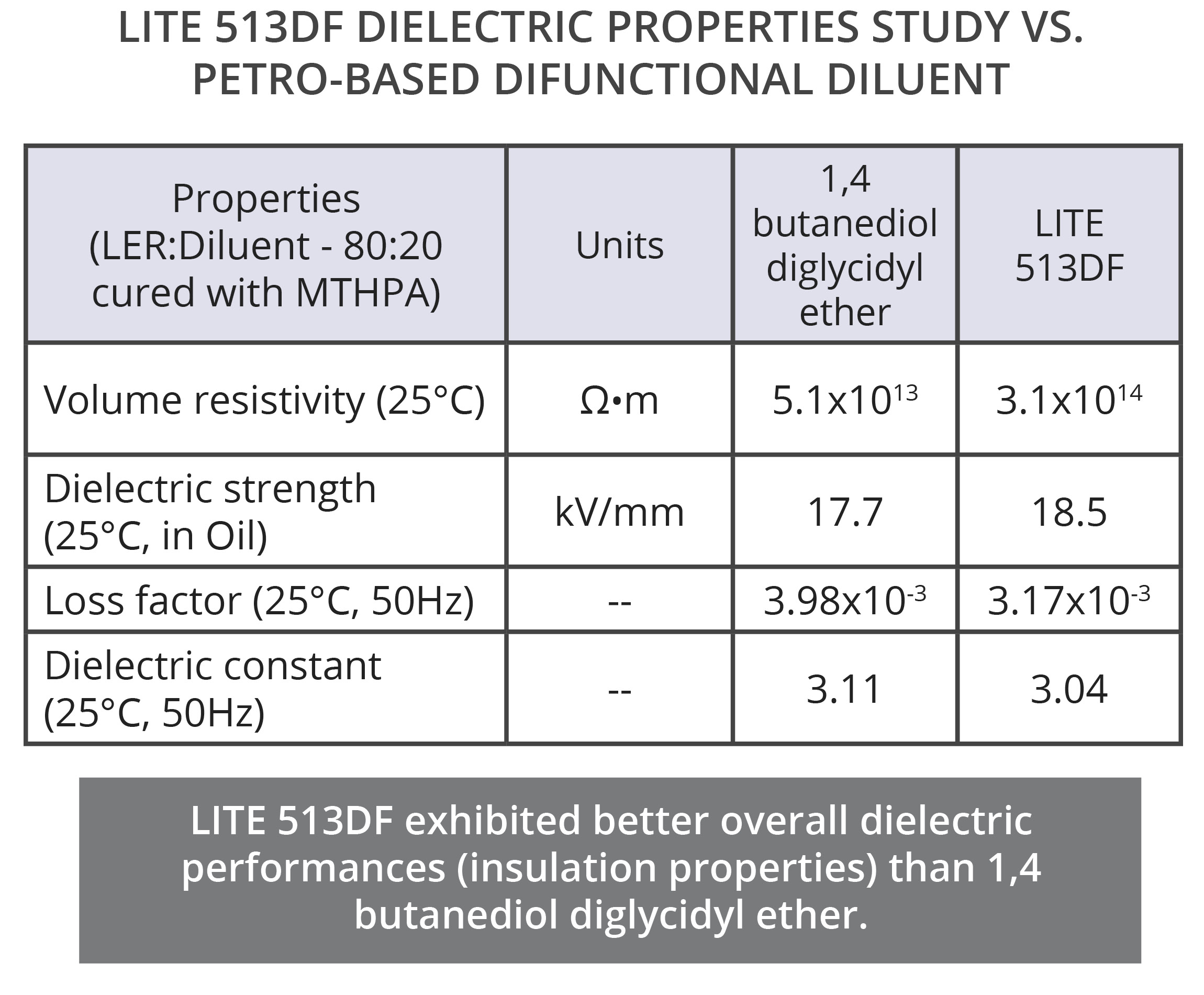

GOOD DIELECTRIC PROPERTIES

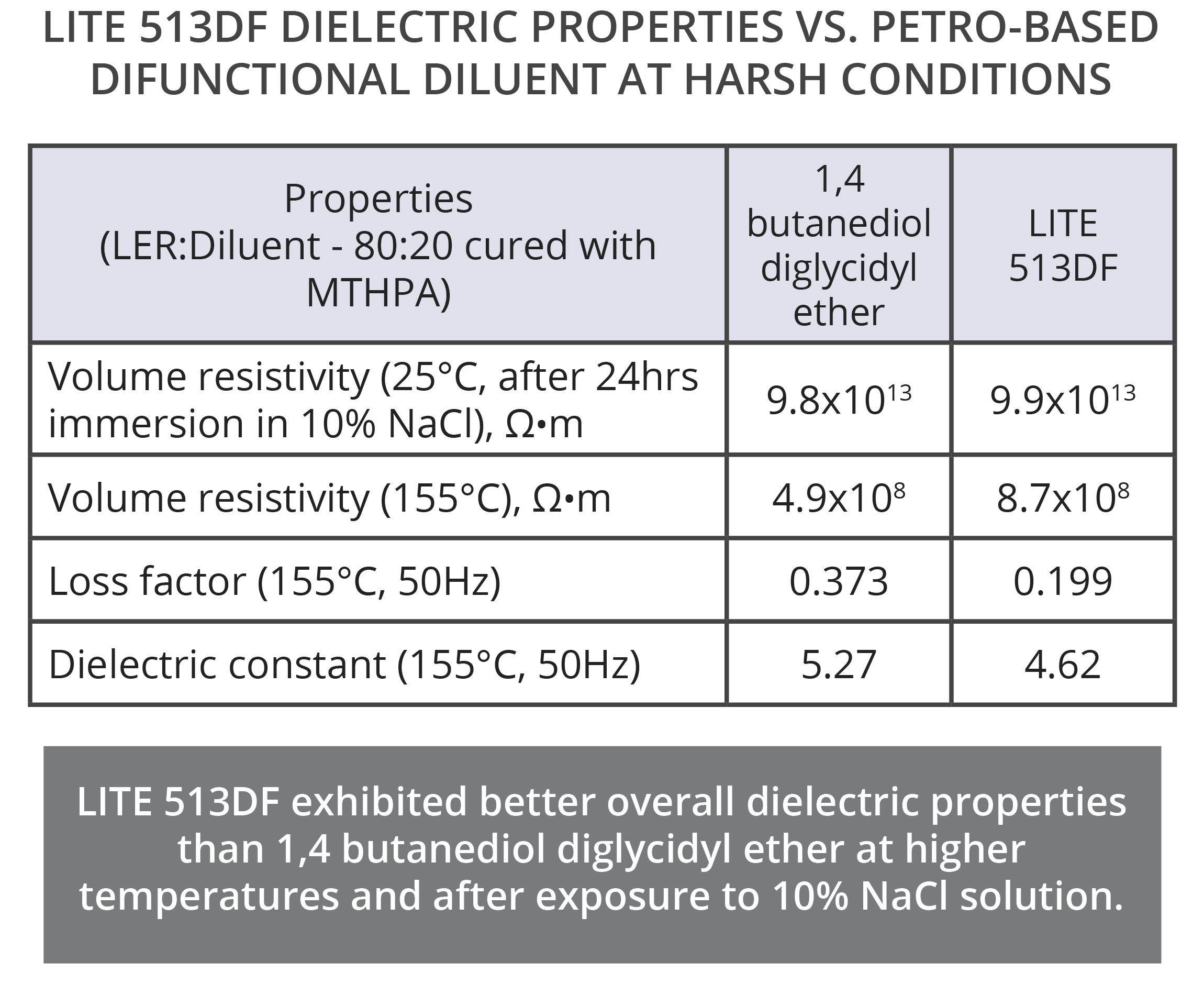

LITE 513DF provides good insulation performance as indicated by its dielectric properties when tested according to IEC 62631 and IEC 60243 standards. In a formulation with Epon 828 at use level of 20% to the resin, cured with MTHPA (Methyl Tetrahydrophthalic Anhydride) and catalyzed by BDMA (Benzyl Dimethyl Amine), LITE 513DF showed excellent results with higher volume resistivity and dielectric strength, and lower loss factor and dielectric constant than competitive 1,4 butanediol diglycidyl ether. Similarly, LITE 513DF outperformed the petroleum-based difunctional diluent when both diluted epoxy systems were exposed to elevated temperatures or a salt solution. The combined properties of LITE 513DF make it a good epoxy diluent and modifier for electrical potting, casting, and encapsulations (impregnating resin).

HIGH BIO-CONTENT EPOXY RESINS AND MODIFIERS

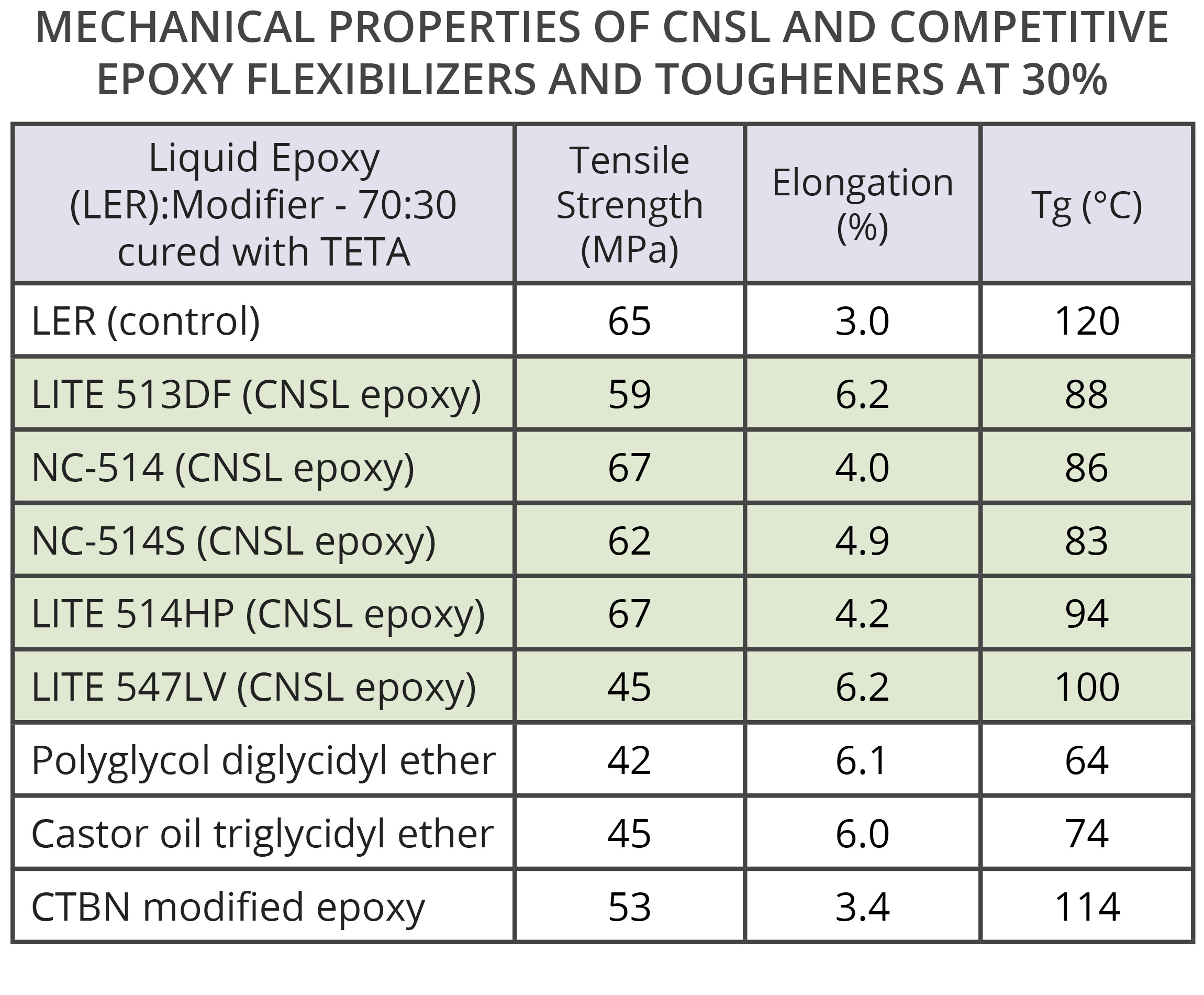

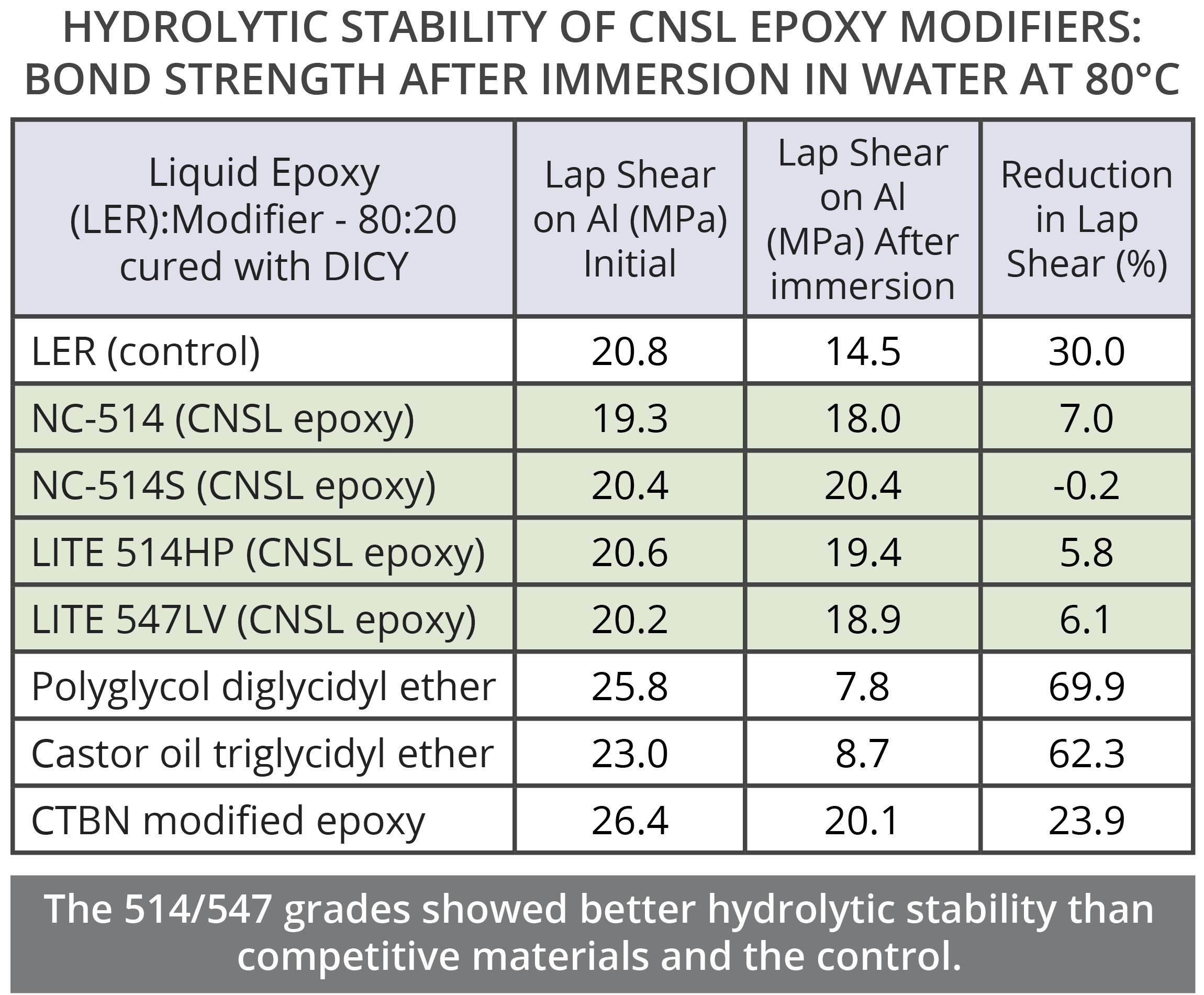

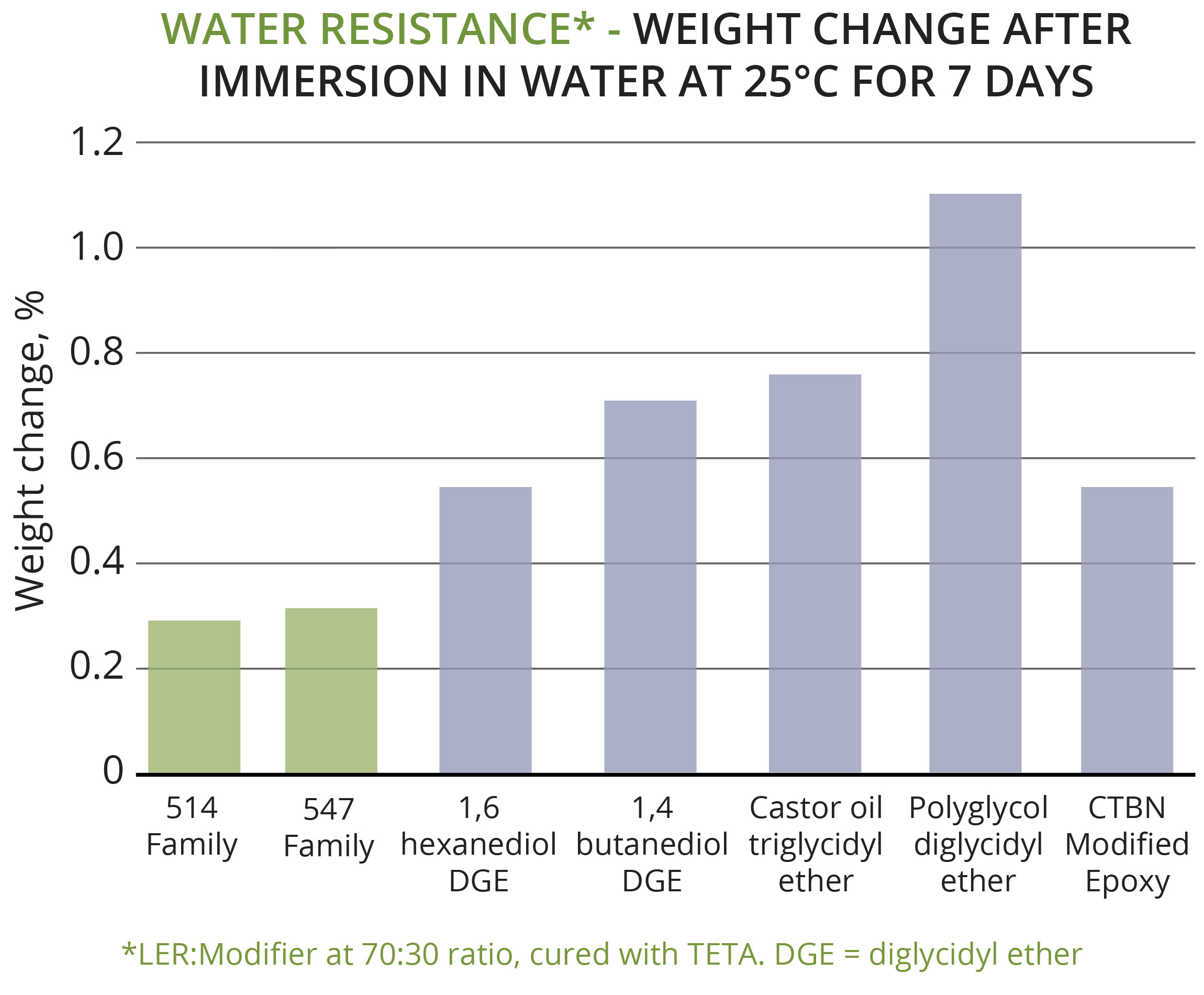

Cardolite offers CNSL-based specialty epoxy resins that can work as modifiers for standard epoxy systems. They provide increased water resistance and hydrolytic stability as well as higher impact resistance and elongation. The effect on mechanical strength can be minimized with the new LITE 514HP grade which allows for a tougher epoxy system.

EPOXY RESINS AND MODIFIERS TYPICAL PROPERTIES

| Product | Type | Color Gardner | Viscosity (cPs) | EEW | HyCl (%) | Documents |

|---|---|---|---|---|---|---|

| LITE 514HP | Epoxy resin | ≤ 10 | 4500 | 280-330 | ≤ 0.5 | TDS MSDS (USA) MSDS (EU) |

| NC-514 | Epoxy resin | 17 | 25000 | 350-500 | ≤ 2 | TDS MSDS (USA) MSDS (EU) |

| NC-514S | Epoxy resin | 12 | 2000 | 350-500 | ≤ 0.5 | TDS MSDS (USA) MSDS (EU) |

| NC-547 | Epoxy novolac resin | 18 | 28000 | 550-850 | ≤ 2.5 | TDS MSDS (USA) MSDS (EU) |

| LITE 547LV | Epoxy novolac resin | ≤ 10 | 700 | 400 | n.a. | TDS MSDS (USA) MSDS (EU) |

514 Series

Cardolite NC-514 and NC-514S are flexible difunctional glycidyl ether epoxy resins. LITE 514HP is a NEW higher purity grade version of this resin that provides higher mechanical strength. The chain of 8 carbons separating the aromatic groups allows this resin to be used in conjunction with traditional epoxy resins to increase flexibility and elongation, bond strength, and water and chemical resistance while minimizing effect on mechanical strength properties as demonstrated by the study shown on this page. In addition, these resins provide excellent water resistance and hydrolytic stability as illustrated by small reduction in lap shear strength after cured resin was immersed in hot water.

547 Series

Cardolite NC-547 is a polyglycidyl ether epoxy novolac resin derived from cardanol. LITE 547LV is a low viscosity, lower EEW and low color version of NC-547. This family of resins can be used in combination with standard epoxy resins to bring additional flexibility including at low temperature while minimizing effect on Tg. In coatings, 547 products provide longer pot life and impact resistance without adversely affecting chemical and water resistance.