WATERBORNE CURING AGENTS

WATERBORNE CURING AGENT OFFERING

Cardolite offers a wide range of curing agents designed for waterborne epoxy coatings. Our portfolio includes solution-type and emulsion-type chemistries with excellent compatibility with most epoxy dispersions. Grades supplied in water do not contain any solvents. However, materials supplied in a variety of glycols are available for zinc rich primers and other low VOC applications. Our curing agents are great options for anticorrosion primers, self-levelers, and midcoats. Some grades are specially formulated for concrete floors and top coats.

Please watch the video on this page to learn more about our products.

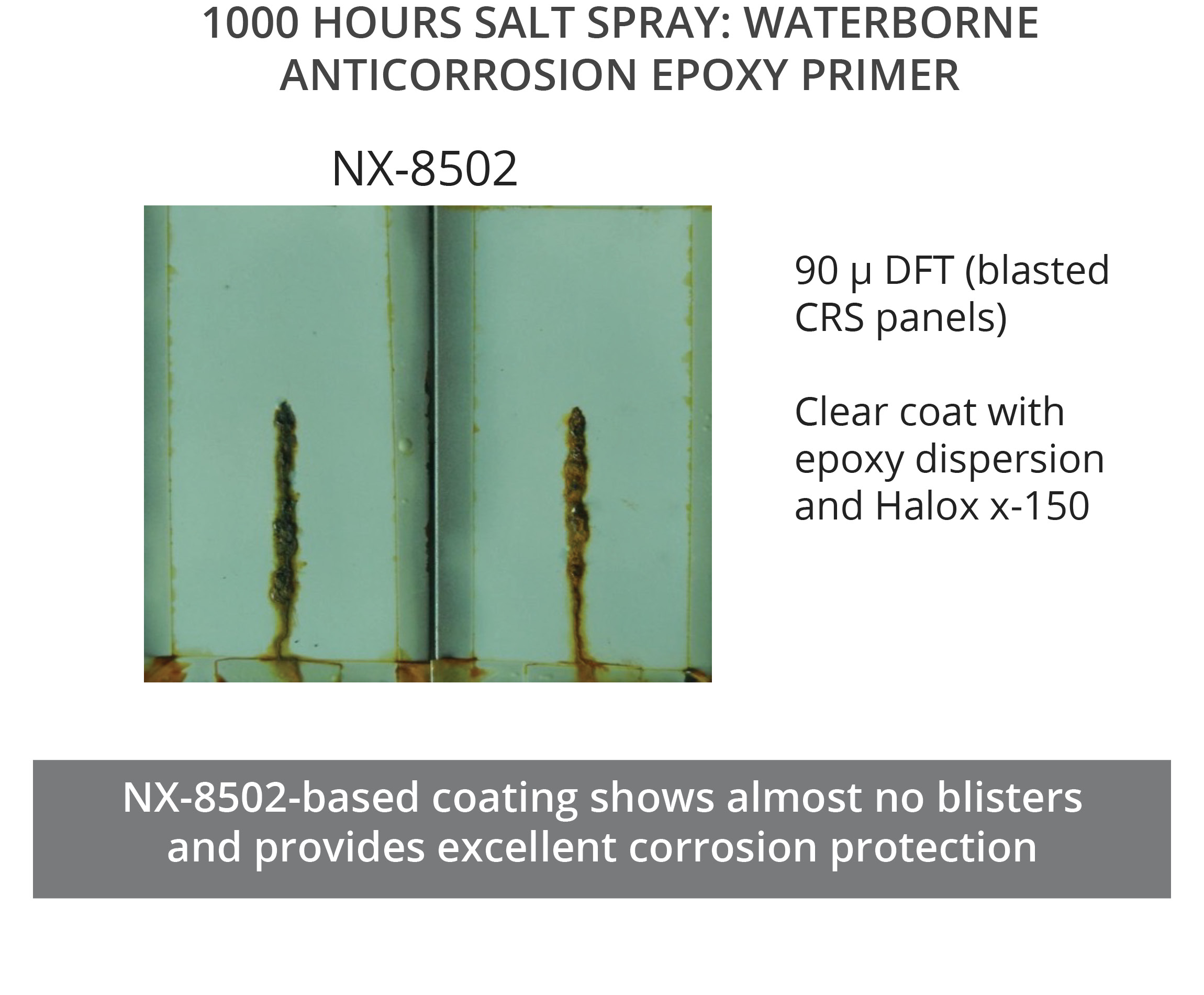

NX-8502: EXCELLENT CORROSION PROTECTION

NOVEL WATERBORNE EPOXY CURING AGENT

NX-8502 is the latest waterborne epoxy curing agent developed by Cardolite Corporation. As with most of our hardeners, this material is free of solvent and can be formulated in zero and low V.O.C. coatings. NX-8502 is designed for high performance anticorrosion coatings that demand long protection of the metal substrate.

This recently developed curing agent provides fast cure and hardness development while delivering long pot life. In addition, NX-8502 can be easily diluted with water for better spray-ability and handling. Moreover, this hardener is compatible with most epoxy dispersions in the market broadening formulation options.

Completely solvent-free!

Excellent corrosion protection

Fast cure with long pot life

Excellent dilution properties in water

Very good compatibility with various epoxy dispersions and resins

Visible end of pot life

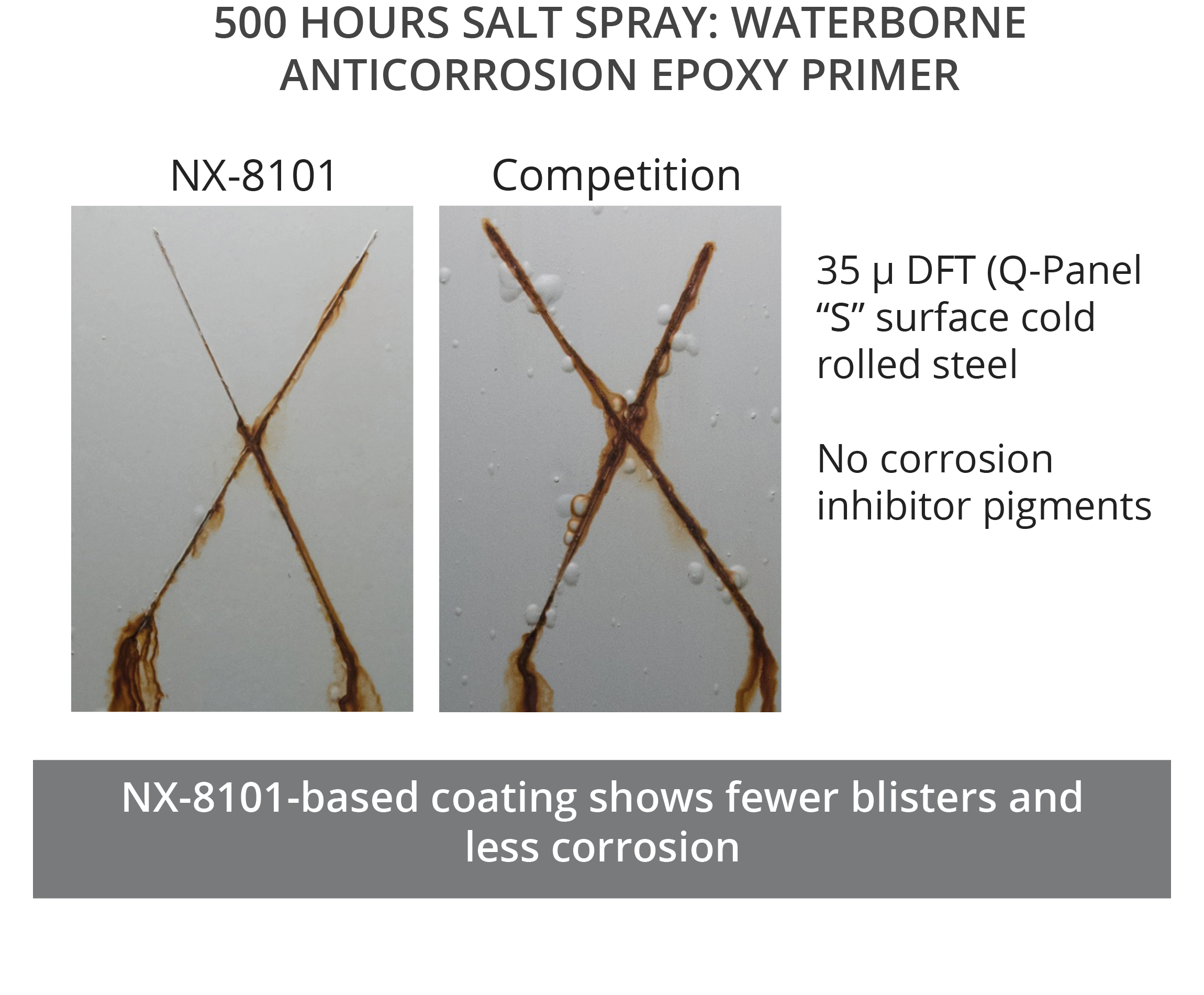

NX-8101: WATERBORNE CURING AGENT FOR ALL SEASONS

FIRST CNSL-BASED, WATERBORNE EPOXY CURING AGENT

The NX-8100 Series is the first CNSL-based waterborne curing agent product line available in the market. Phenalkamine grade NX-8101 is designed for cost effective water-based metal primers that require high corrosion protection and concrete epoxy primers and self-levelers that require quick return-to-service, and excellent adhesion to concrete and top coats.

Phenalkamines are highly hydrophobic due to the long aliphatic side chain present in cardanol, which results in excellent corrosion and water resistance. However, that also makes it very challenging to synthesize cardanol-based materials that are stable in water. Through proprietary technology, Cardolite Corporation developed NX-8101, the first phenalkamine supplied in water that does not contain solvent or glycols, and does not require the use of additional emulsifiers to work well in epoxy systems.

This new low odor epoxy curing agent is supplied in water and does not contain or require any solvents in the formulation to deliver excellent performance. Its good compatibility with standard liquid epoxy and solid epoxy dispersions, and easy reducibility in water, broadens its use and allows for cost effective industrial coatings.

Completely solvent-free!

Excellent corrosion protection

Fast cure and hardness development even at 10°C/80% RH

Excellent adhesion over dry and damp concrete and to various substrates

Compatible with standard liquid epoxy and solid epoxy dispersions

Does not demand emulsifiers and it is easily reducible in water in epoxy systems

Visible end of pot life

Cost effective!

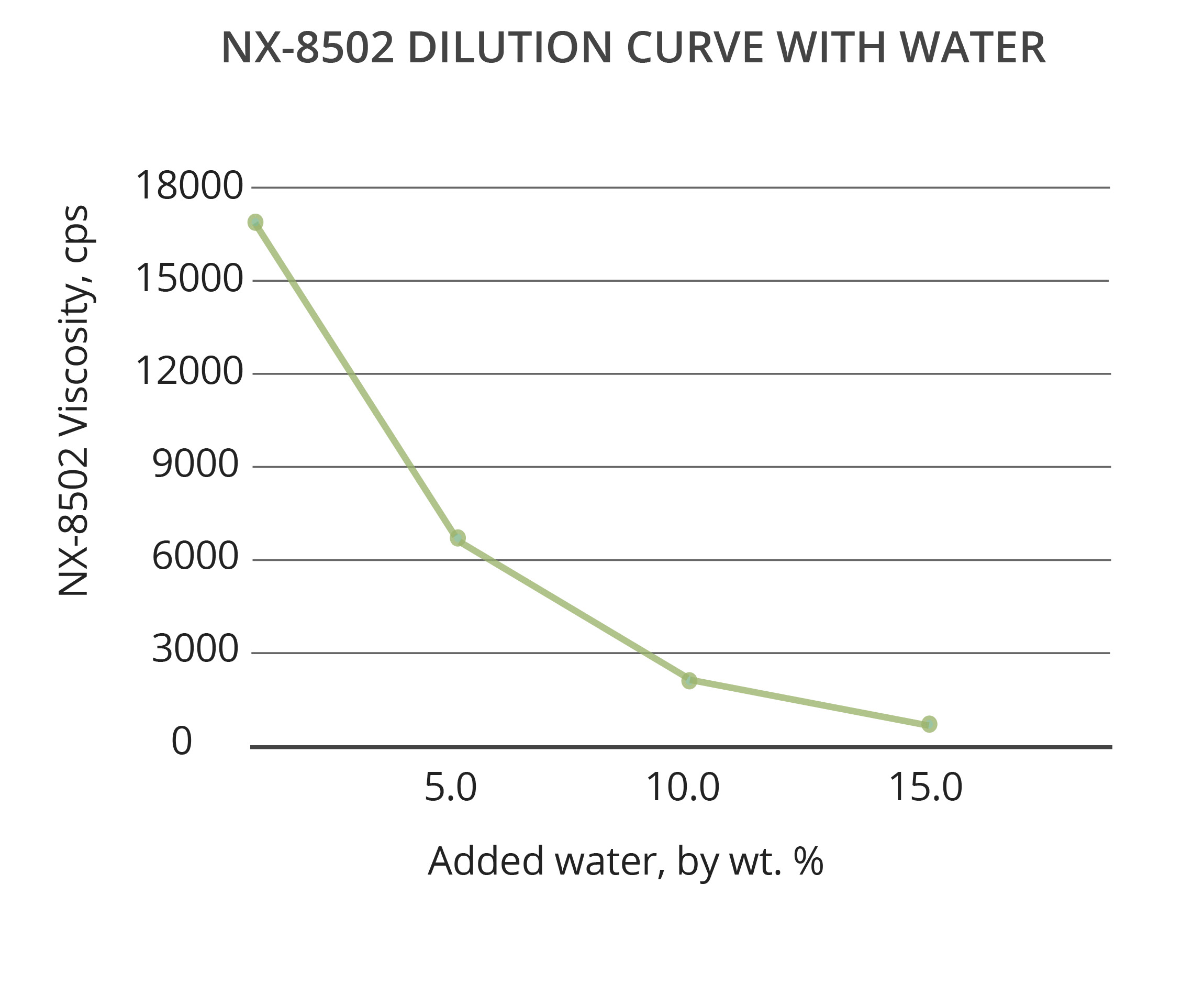

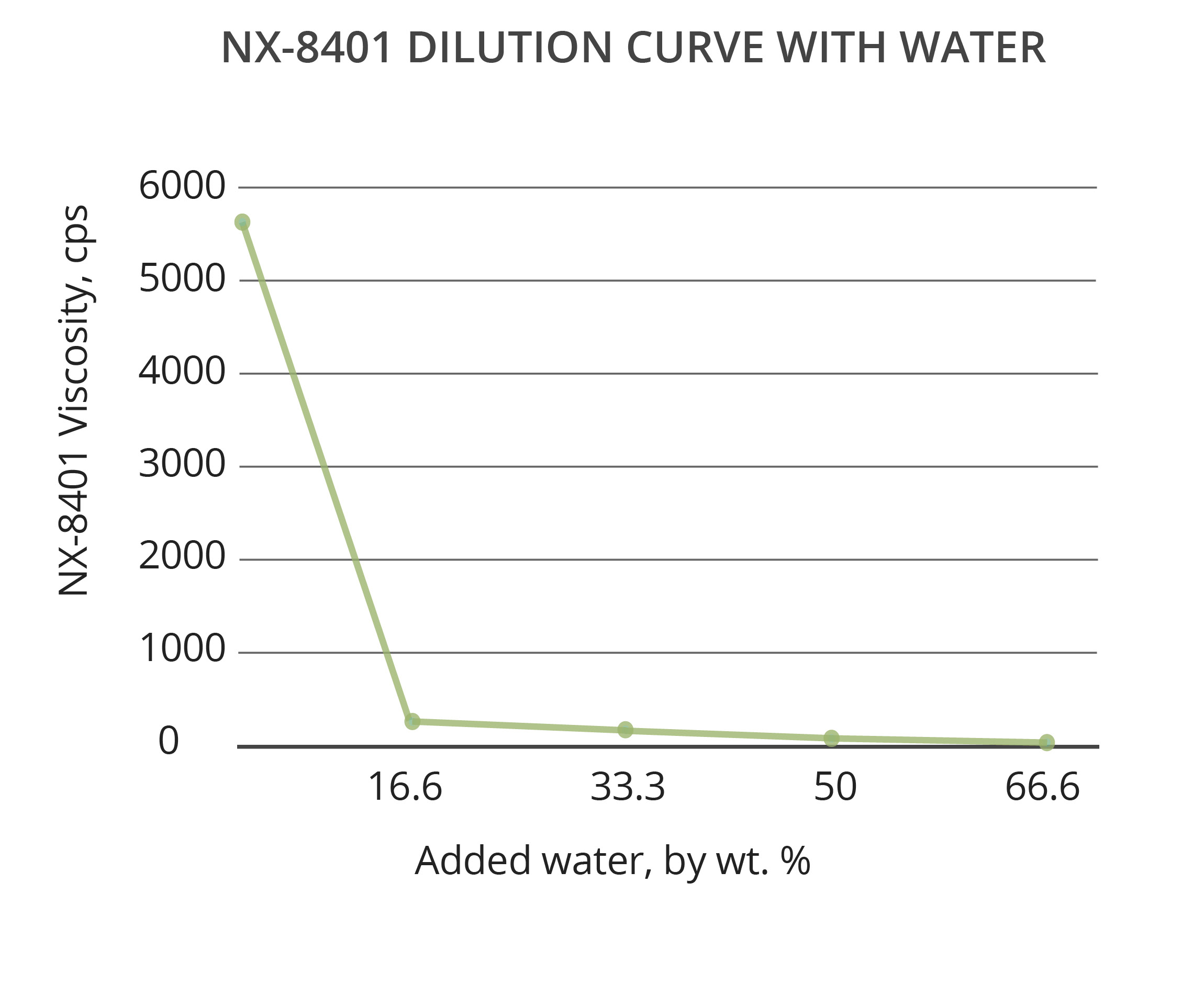

EASILY REDUCIBLE WITH WATER IN EPOXY SYSTEMS

Even tough NX-8101 is high in viscosity, it can be easily reduced to very low viscosities with the addition of water once mixed with an epoxy resin.

CONCRETE AND METAL PROTECTION

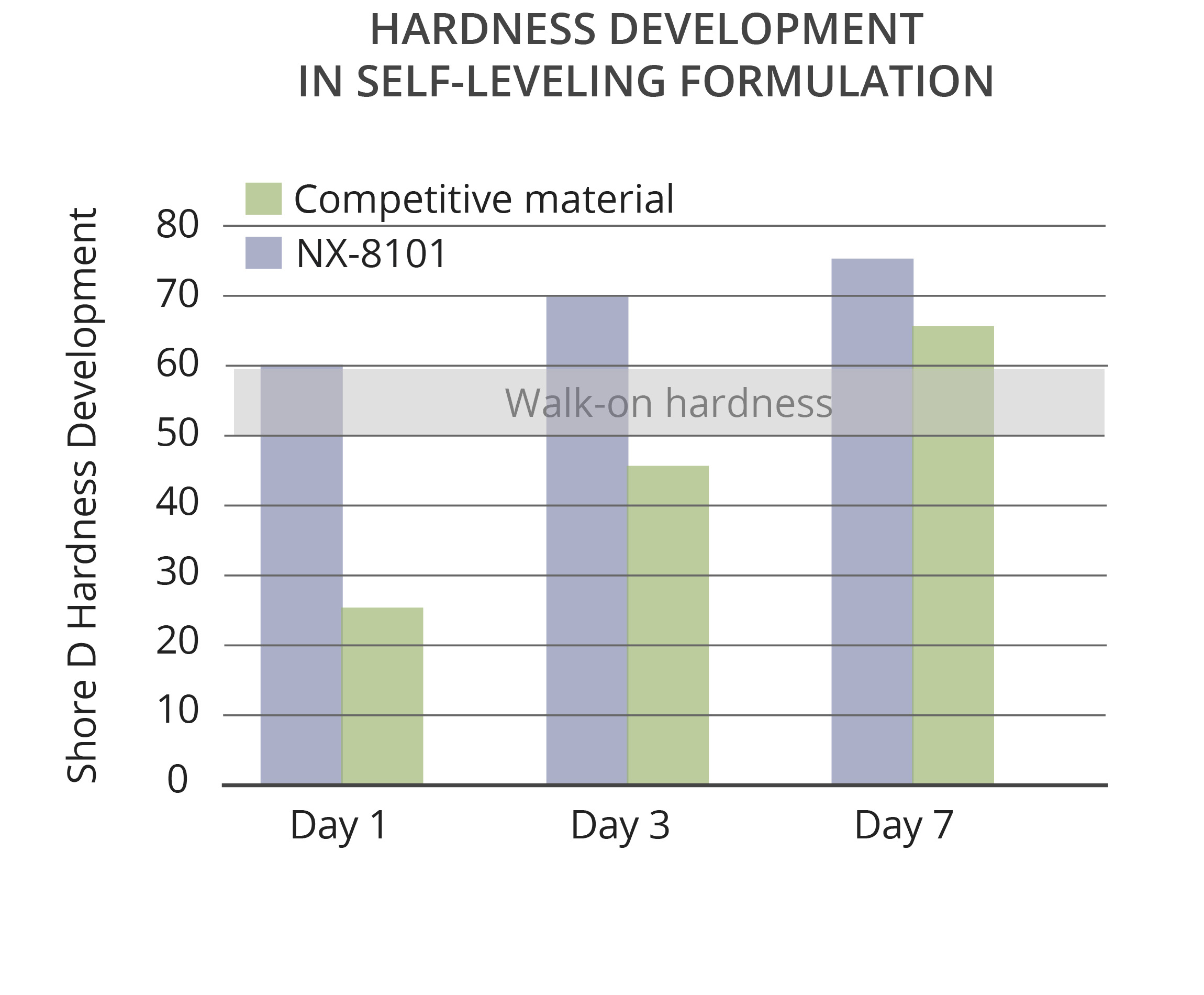

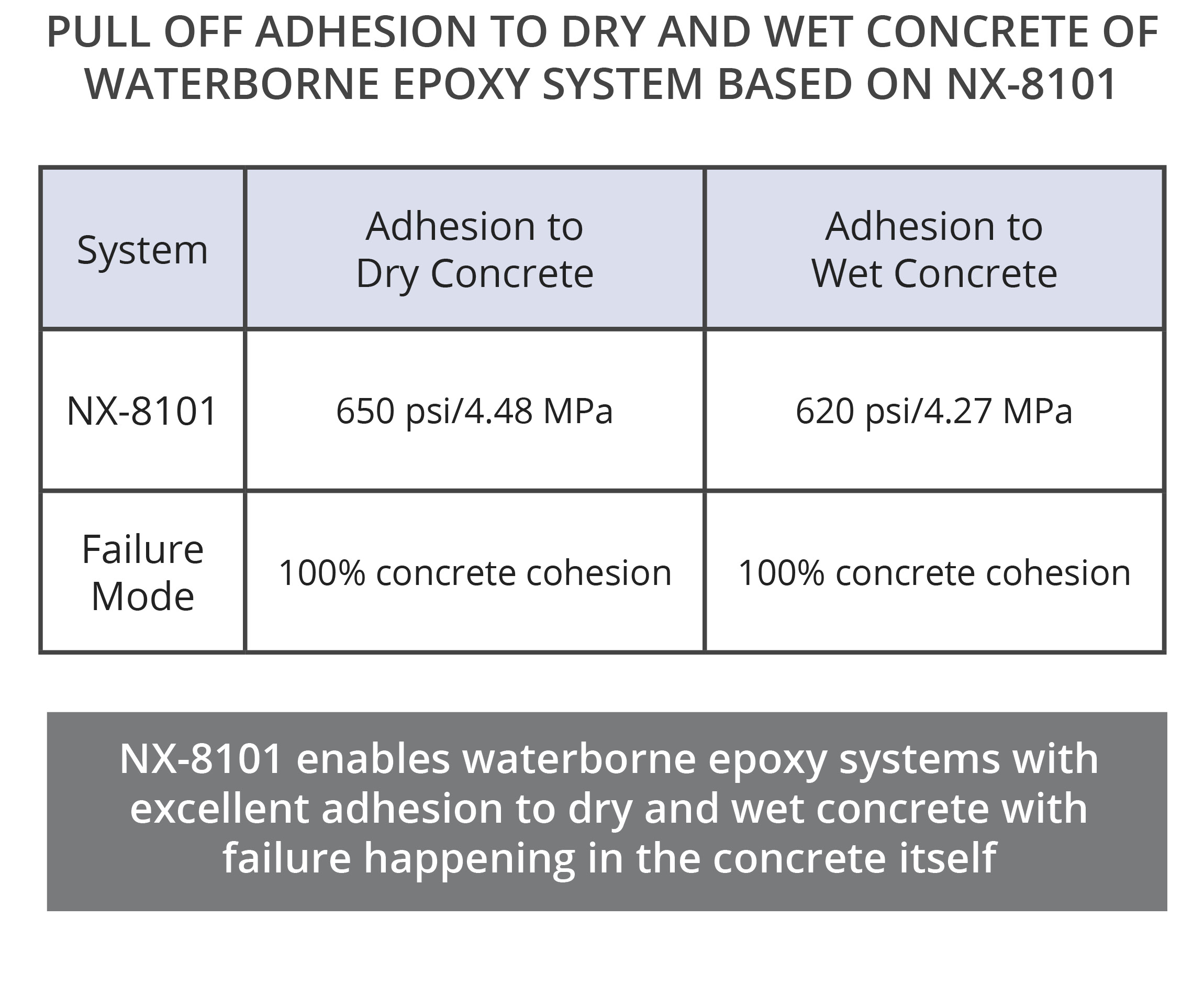

NX-8101 provides very fast hardness development at room temperature and at lower temperature and higher humidity (10°C/80%RH), which are properties inherited from CNSL technology. This hardener is ideal for concrete primers and self-levelers for fast walk on times. Moreover, this waterborne curing agent provides high pull off adhesion values on dry and wet concrete that lower failure risks on poorly prepared surfaces.

Furthermore, NX-8101 also maintained the excellent corrosion performance of solvent-borne phenalkamine counterparts. The hydrophobicity and adhesion and wetting properties of NX-8101 lead to long-term corrosion protection as demonstrated by salt spray performance. However, different from many competitive materials, NX-8101 also delivers early corrosion resistance due to the fast cure and consequently, sufficient crosslinking shortly after application as shown by results after a 16-hour cure at 25°C followed by immersion in 50°C tap water for 48 hours. NX-8101-based epoxy clear coats provided good corrosion performance after a 16-hour cure showing no blisters and similar performance to the same system immersed after a 5-day cure.

NX-8101 IN CONSTRUCTION ADHESIVES

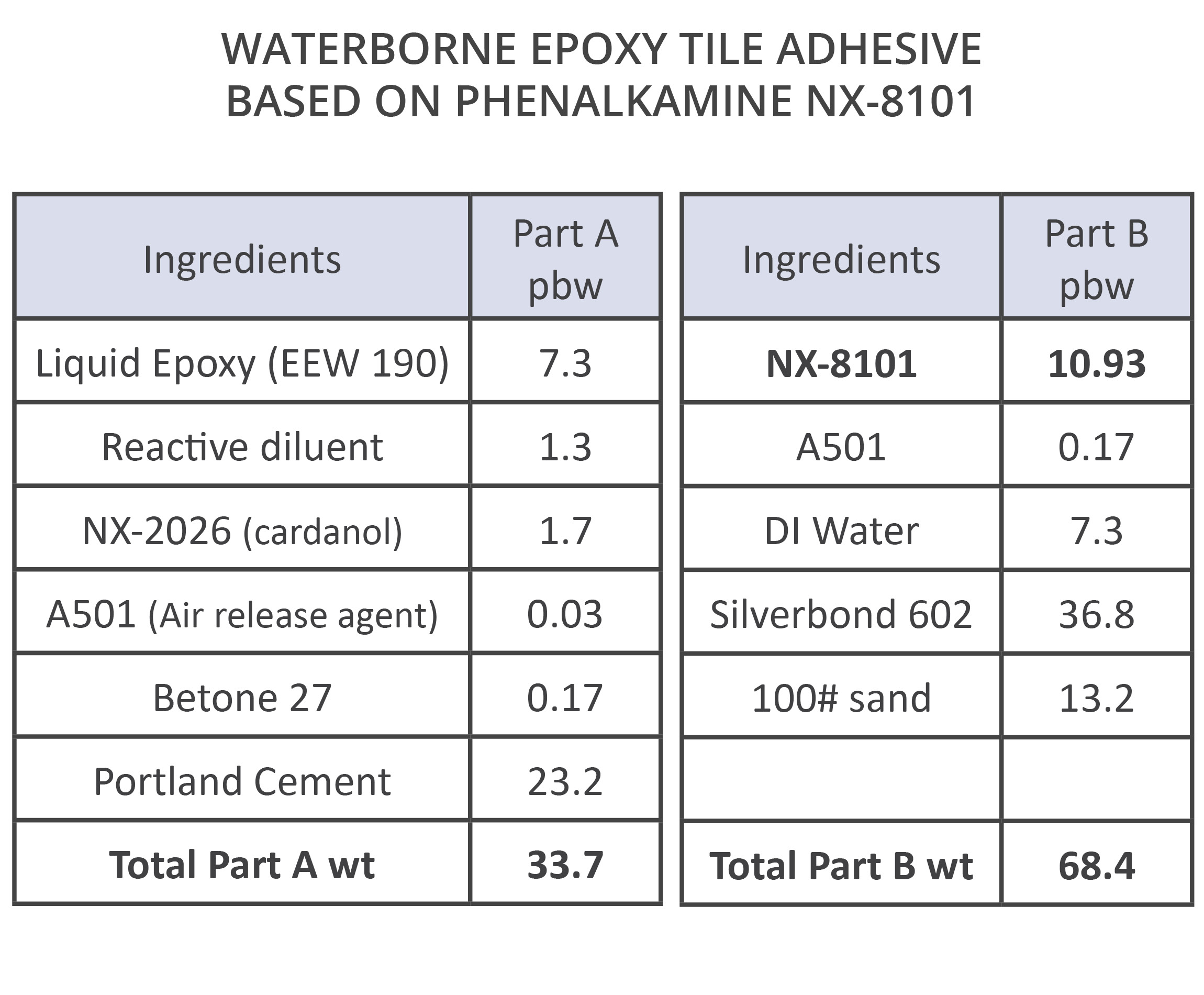

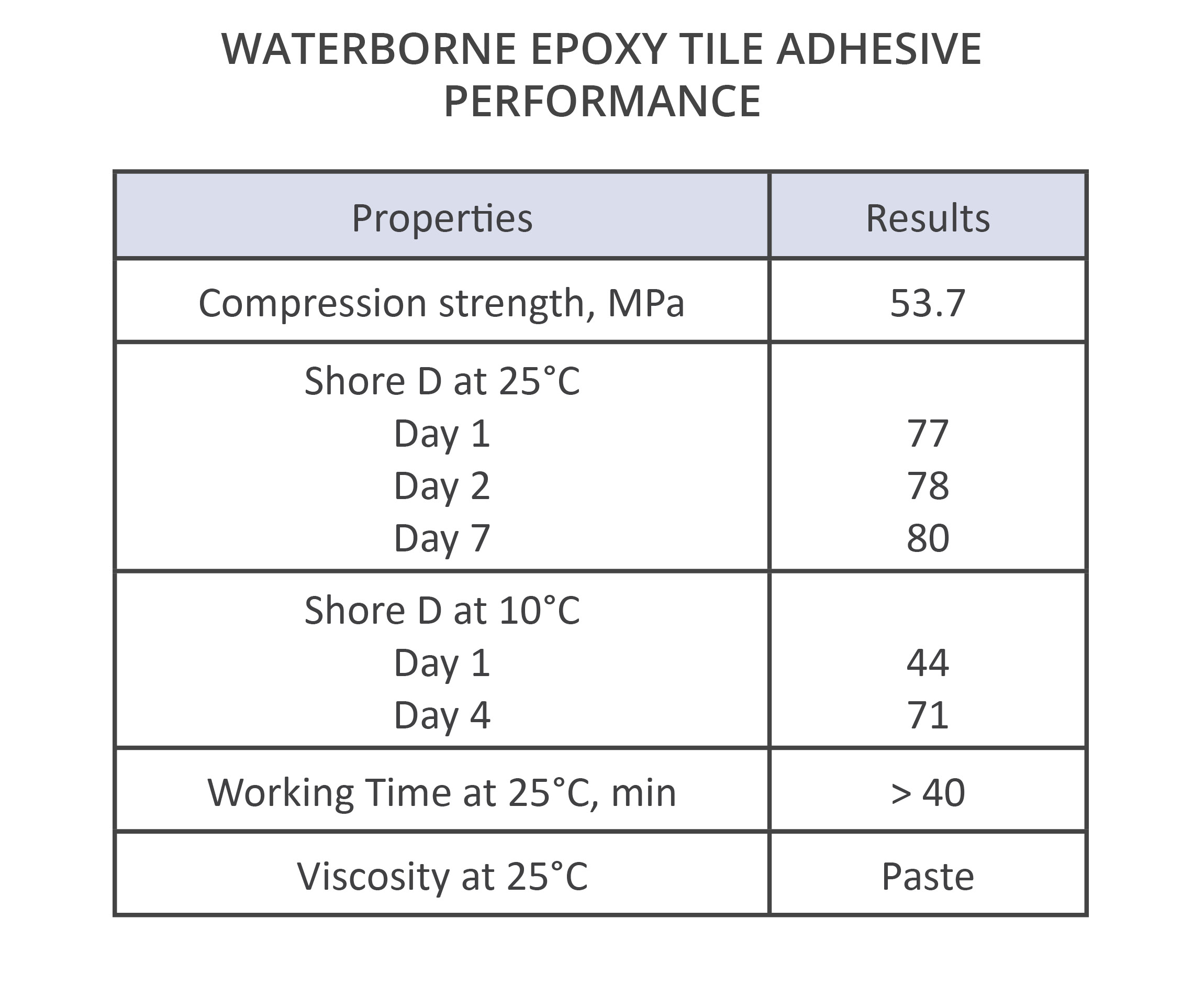

NX-8101 is also suitable for adhesive applications such as grouts and tile adhesives. In those systems, NX-8101 can be formulated without solvents to deliver fast ShoreD hardness development even at lower temperatures. In the formulation below, NX-8101 enables tile adhesives with high compression strength, longer working hour (good washability), and good handling properties (ease of mixing).

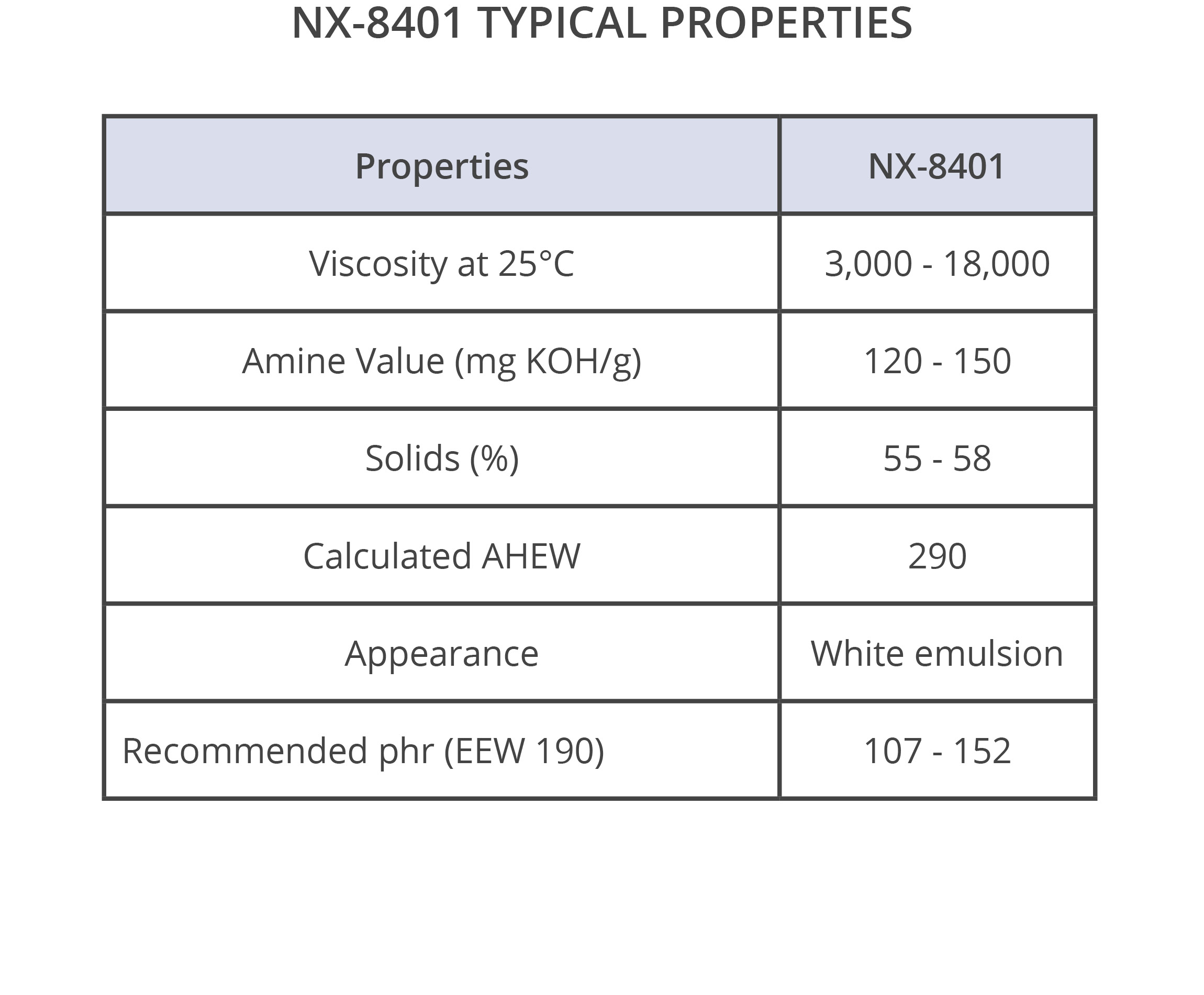

NX-8401: EMULSION TYPE CURING AGENT

NX-8401 WATERBORNE EMULSION CURING AGENT

NX-8401 is a new, completely free of solvent, low viscosity and easily reducible with water curing agent for the formulation of zero and very low V.O.C. coatings. The excellent compatibility of NX-8401 with various epoxy dispersions and its ability to easily disperse pigments and fillers give coatings scientists wide latitude to formulate high performance waterborne epoxy coatings.

NX-8401 was specially designed for anticorrosion coatings applications that require long lasting substrate protection. Coatings based on NX-8401 provide superior corrosion protection even at thin film thickness with excellent adhesion to various types substrates such as blasted and cold rolled steel, galvanized steel, aluminum, and concrete. These coatings can be quickly recoated with typical topcoat technologies such as acrylics and polyurethanes in room temperature or baked cure applications. The development of good anticorrosion properties after short cure cycles enables fast productivity and cost savings. Moreover, the fast recoatability does not come at the price of workability. On the contrary, coatings based on NX-8401 are of long pot life regardless of the epoxy dispersion used lowering risks of failure in the field.

Additional benefits of NX-8401 include increased flexibility and improved color retention for formulators considering epoxy coatings as an option for topcoats.

Solvent-free, low viscosity easily diluted with water

Good compatibility with various epoxy dispersions

Excellent adhesion to various metals

Superior anticorrosion properties even after short cure cycles

Fast recoatability with topcoats

Very long pot life with improved flexibility

Good color stability

Easily disperses pigments and fillers

Cost-effective!

EASILY REDUCIBLE WITH WATER IN EPOXY SYSTEMS

NX-8401 can be easily diluted with water by itself or after the addition of an epoxy dispersion.

NX-8501: WATERBORNE CURING AGENT WITH IMPROVED UV RESISTANCE

VERSATILE CURING AGENT FOR METALS: NX-8501

Our new NX-8501 is a waterborne curing agent for epoxy coatings and adhesives. This completely solvent free curing agent enables zero and low VOC formulations without compromising performance. NX-8501 is a solution-type curing agent supplied at 80% solids in water. This material is easy to handle due to its low viscosity and ability to be further diluted by water or other co-solvents. NX-8501 is also compatible with various epoxy dispersion resins giving formulators latitude to work.

NX-8501 provides fast cure properties and hardness development regardless of the epoxy resin selected. Despite the fast dry speed, NX-8501 delivers long pot life with 3 to 4 hours working time achieved in our studies. Amongst all Cardolite’s waterborne epoxy curing agents, NX-8501 shows the best weatherability properties with low yellowing upon exposure to UV light.

Solution-type, solvent-free and low viscosity at high solids

Good compatibility with various epoxy dispersions

Excellent adhesion to various metals (blasted and non-blasted)

Superior anticorrosion properties to challenging substrates

Fast recoatability with topcoats (as fast as 15 minutes)

Long pot life

Very good color stability

Easily disperses pigments and fillers

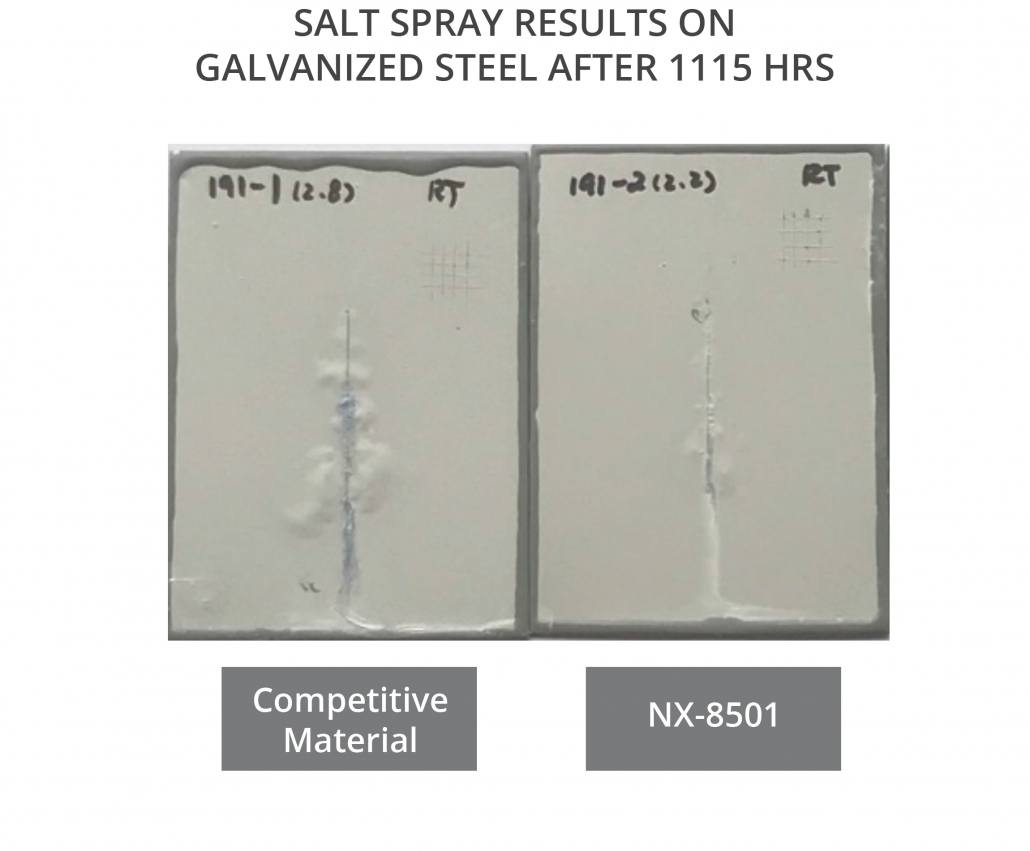

Corrosion Protection for Various Substrates

Coatings based on NX-8501 demonstrated excellent adhesion and anticorrosion performance to a wide range of substrates. That included challenging non-blasted surfaces commonly used in automotive and agricultural and machinery equipment. More specifically, our evaluation looked at NX-8501 based primers on untreated cold rolled steel, aluminum alloy, galvanized steel, and stainless steel panels. All those systems successfully withstood long exposure of over 1500 hours in the salt spray cabinet. NX-8501 based primers also did very well on blasted steel surfaces as encountered in marine and protective coating applications. These coatings demonstrated good surface tolerance by providing excellent corrosion protection even over rusted panels. All systems were tested at low film thickness and were suitable options as primers, midcoats and direct-to-metal (DTM) coatings.

Moreover, NX-8501 based primers can be quickly recoated by top coats in wet-on-wet applications. Our evaluations show that NX-8501 based epoxies can be recoated with polyurethanes in as fast as 15 minutes after application. Cure can take place at room temperature or in a 60°C oven. The final epoxy-polyurethane system provides excellent gloss (no die-back) and long lasting corrosion protection. This makes NX-8501 a great option for automotive refinish and other applications that require quick turnaround time.

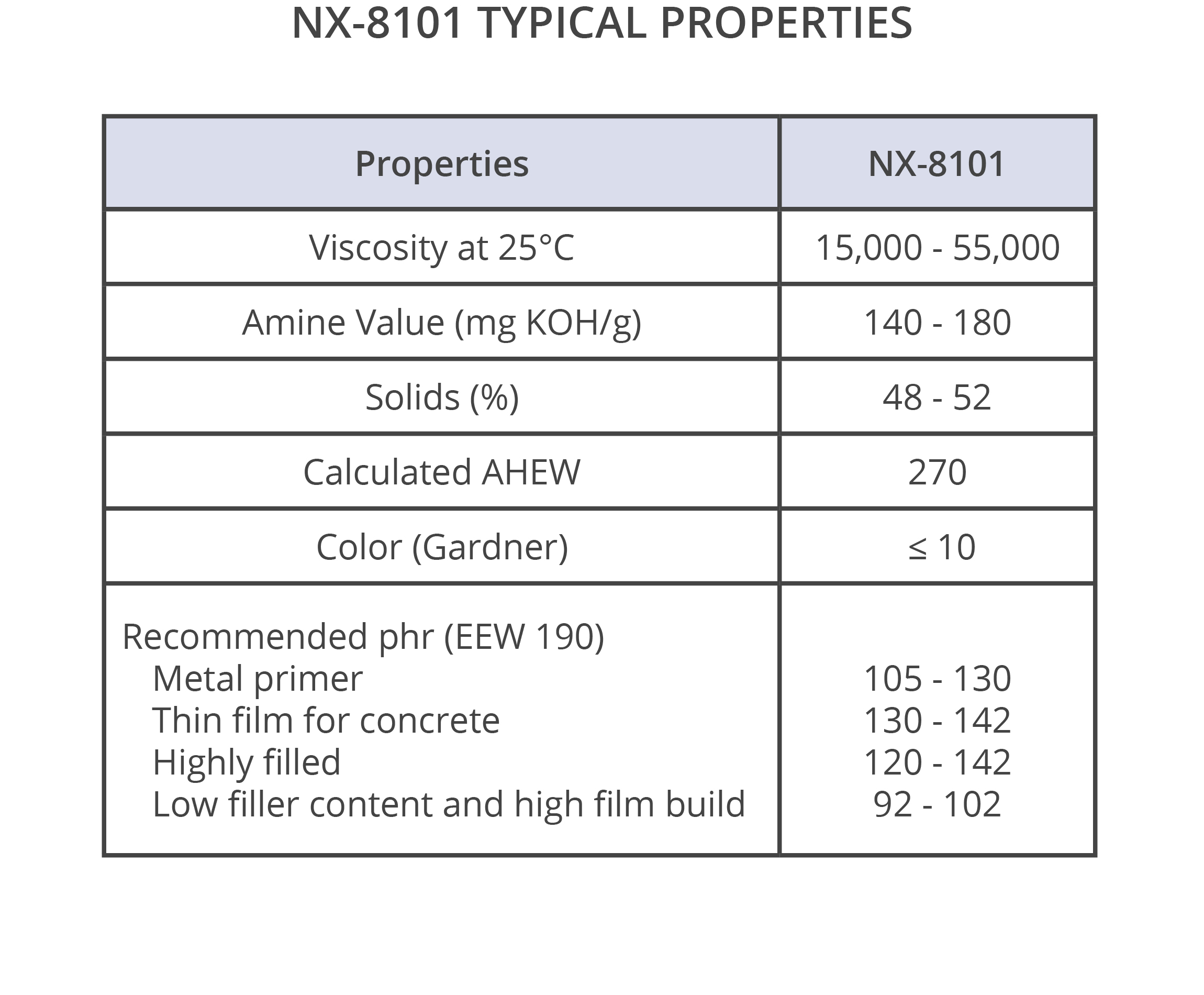

WATERBORNE CURING AGENTS OFFERING

| Curing Agent | Color (Gardner) | Solids (%) | Viscosity (cPs) @25C | AHEW | Chemistry | Description | Recommended Applications* | Documents |

|---|---|---|---|---|---|---|---|---|

| NX-8101 | 8 | 50% in water | 35000 | 270 | Waterborne | Fast hardness development, excellent corrosion protection and stain resistance. Versions in glycols available. | M&P, Ind&Trans, CP, B&C Adh | TDS MSDS (USA) MSDS (EU) |

| NX-8401 | white emulsion | 55% in water | 7000 | 290 | Waterborne | Easy handling, fast recoatability, excellent corrosion protection. | M&P, Ind&Trans, B&C Adh | TDS MSDS (USA) MSDS (EU) |

| NX-8402 | white emulsion | 45% in water | 18000 | 316 | Waterborne | Easy handling, fast cure speed, excellent corrosion protection. | M&P, Ind&Trans, CP, B&C Adh | TDS MSDS (USA) MSDS (EU) |

| NX-8501 | 8 | 80% in water | 5600 | 165 | Waterborne | Excellent corrosion protection and good yellowing resistance. | M&P, Ind&Trans, CP, B&C Adh | TDS MSDS (USA) MSDS (EU) |

| NX-8502 | 6 | 45% in water | 15000 | 424 | Waterborne | Excellent corrosion protection and fast cure with long pot life | M&P, Ind&Trans, CP, B&C Adh | TDS |

*Abbreviations in the Applications column:

Marine and Protective Coatings – M&P

Industrial and Transportation Coatings – Ind&Trans

Solvent-free Floor Primers – CP

Top Coats – TP

Building and Construction Adhesives -B&C Adh

Industrial and Transportation Adhesives – I&T Adh

Two-component Composites – 2k Comp